A common request across Eddyfi Technologies relates to the integration of ultrasonic scanning for wall thickness and corrosion mapping within pipelines. We have demonstrated quite frequently the ability to add ultrasonic testing (UT), pulsed eddy current (PEC), or even phased array (PA) integration to our surface mounted crawlers. However, a major consideration recently is the shift from the market to move towards more and more unmanned inspections. Generally, these inspections take place inside pipelines and other vessels, and the type of inspection robot used must be considered. Several solutions exist for short distance UT or corrosion mapping, and we offer a number of these already.

The current market demands for UT integration to add analytical acquisition data to visual inspection. We are progressing to a time where unmanned entry is mandatory and as an advanced NDT technology company, it is paramount that we act swiftly to this demand to ensure our customers are furnished with a technology solution as industry develops.

Playing to our strengths

As a customer – if you intend to shut down a pipeline, or some plant, then in certain circumstances it would be beneficial to obtain more information than what visual inspection would deliver alone. Therefore, being able to collaborate internally and make use of the vast array of sensor technology available by Eddyfi Technologies is incredibly advantageous.

Eddyfi Technologies is backed by multiple centers of excellence and sales offices worldwide, boasting powerful NDT methods:

- Phased Array and Conventional Ultrasonics

- Eddy Current Array

- Pulsed Eddy Current

- Magnetic Flux Leakage

- Alternating Current Field Measurement

- Guided Wave Ultrasonics

- Remote Visual Inspection and Robotics

No other company, operating under one umbrella, has the same access to this technology in house. Paired with Eddyfi Technologies’ dynamic approach to business, we are able to develop a corporate environment where communication flows quickly and precisely through centers of excellence, and through strong connections within product management and engineering departments, we are in a great position that facilitates interaction, ideation, and integration to develop multi-faceted solutions, spanning multiple technologies.

Robotics are the glue that binds us

In considering robots as platforms for inspection, rather than an enveloped inspection system, we can start to see how we can use our vast experience in robotic delivery and integrate with sensors from other centers of excellence (and sometimes external partners) to deliver true, value added solutions, rather than just boxed products.

The ability to obtain more than just visual data when closing large value assets, or sections of pipeline for inspection is becoming more and more important. Collecting additional ultrasonic/eddy current data has become the number one request for these inspections using robotic crawlers. Unfortunately, most solutions available either cannot incorporate ultrasonic/eddy current or can only integrate over short distances. As such, solutions have historically been limited to custom solutions with low volume, long turnaround times, high maintenance costs, and even higher prices.

Eddyfi Technologies looks to change that using this platform to highlight the combination of two technologies resulting in a solution that answers a question that has had no answer for some time.

How to get more data without more work

For the application considered here, we look at a section of pipeline nominally 50 meters (164 feet) in length with a nominal diameter of 700 millimeters (28 inches).

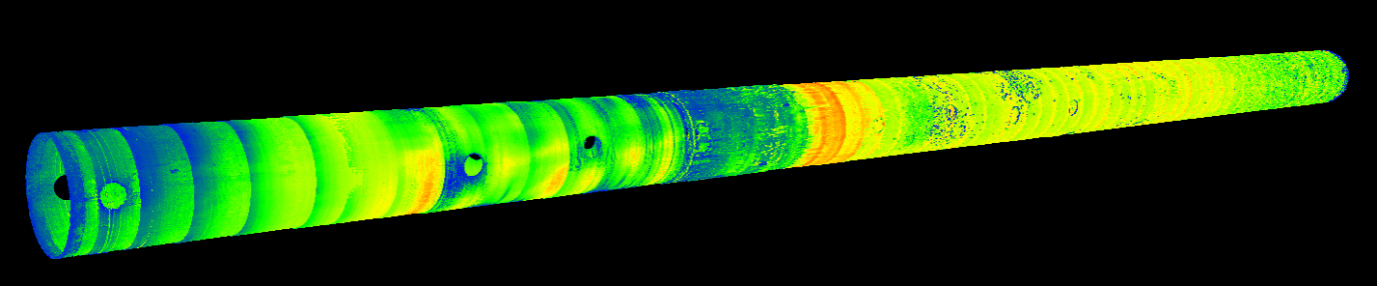

We wanted to look at the possibility of carrying out a complete visual inspection of the interior of the line and at the same time capture as close to 100% coverage for PAUT giving wall thickness measurement/remaining wall, while at the same time creating a 3D model of the line using a laser scanner to give additional information relating to internal pipe wall condition.

The desired output was a 3D pipeline model with a visual overlay of the inspection data pinned, allowing for periodic repetition of inspection, and therefore, semi-automated condition monitoring.

The Beyond Current solution

The key requirements for the robotic inspection system related mainly to its capability to fulfill three key operational considerations:

- Travel vertically within pipelines

- Be suitable to transport, deliver, and apply the UT measurement solution

- Visually inspect the interior of the pipe, while operating a laser scanner for laser profilometry.

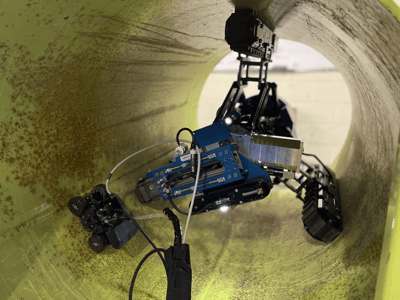

The VersaTrax™ Y-series (formerly known as TriTrax™) vertical crawler is a robot that uses three equidistant circumferentially engaged tracks, maintaining the central position of the robot within the pipe – the best place for any visual inspection equipment to be mounted offering the best, most unobstructed view when navigating and reducing the effects of halation or exposure compensation.

Given its capacity to travel 1,000 m (3,280 ft), operate in pipelines between 380 and 916 mm (15 to 36 in), manipulate and position a tooling arm, and shuttle 360 degrees circumferentially, the VersaTrax Y-Series met all project prerequisites.

Visual inspection system

VersaTrax is coupled with two integrated cameras:

- The front-mounted Spectrum™ 90 provides remote visual inspection (RVI) with high quality real-time video footage. It is one of Eddyfi Technologies’ most popular cameras providing amphibious pan, tilt, and zoom (PTZ) functionality in a tiny package. Incorporating a range of options and extended capabilities, the Spectrum 90 is ideal for the remote visual inspection of pipelines or any industrial structure that precludes manned entry. Due to its unique spherical head design, all functionalities can be utilized without ever changing the camera's working envelope – reducing the likelihood of the crawler getting stuck (compared to other third-party camera designs).

- A rear-mounted sapphire camera enables UT probe observation and navigation, tether management overview, return journey navigation, and of course, an element of RVI.

For this inspection, the Spectrum 90 is considered the primary camera and provides the highest quality overview, observation of the inspection area, and UT probe position (n.b. the probe position sensor is in place alongside the probe manipulator/actuator, and a positive signal appears on the acquisition software, Swift, when the probe is correctly mounted).

NDT data acquisition

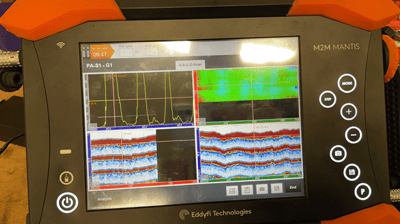

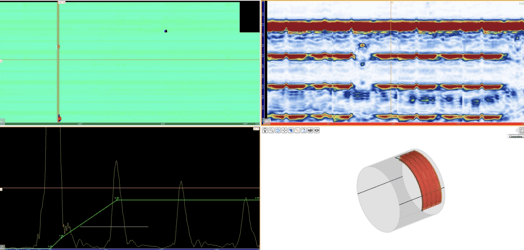

For this project, we have a suitable acquisition device joined with the robotic crawler. The unit is connected to the phased array probe head using a custom 30-m (100-ft) cable. The system allows for the NDT setup using Capture™ software and is separate from the robotic controller; alternatively, the data acquisition unit could be remotely controlled using a VNC Ethernet connection to the Gekko® portable PAUT instrument. This solution benefits from the best ultrasonic electronics and software the industry has to offer.

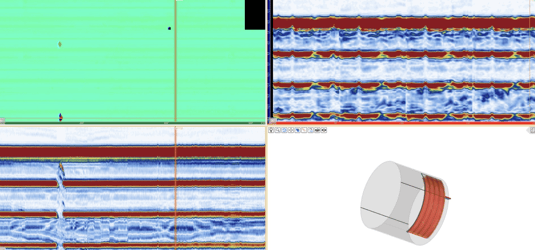

With advanced filtering, it can quickly and accurately inspect materials for wall thickness deterioration. The embedded software enables unique ultrasonic processing and (post inspection) analysis. Capture software has unique corrosion mapping features; this includes gate synchronization, compensation, and straightening. This ensures exact wall thickness measurements and can provide clear C-scans, B-scans, and 3D images if needed.

With advanced filtering, it can quickly and accurately inspect materials for wall thickness deterioration. The embedded software enables unique ultrasonic processing and (post inspection) analysis. Capture software has unique corrosion mapping features; this includes gate synchronization, compensation, and straightening. This ensures exact wall thickness measurements and can provide clear C-scans, B-scans, and 3D images if needed.

Probe design

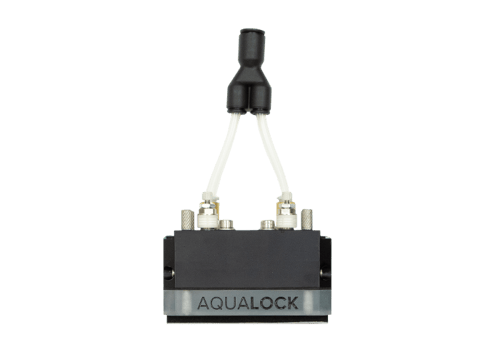

Designed to be used in a wide variety of industries, Eddyfi Technologies’ unique Aqualock water column houses a 64-element linear phased array probe with a frequency of 7.5 Mhz. The 15-mm(0.6-in) aqua lock allows inspecting wall thicknesses up to 60 mm (2.4 in). Higher water boxes are available for the inspection of even thicker materials.

High Probability of Detection (PoD)

High Probability of Detection (PoD)

Compared to spot thickness measurements, the range of semi-automated phased array scanners and PAUT Instruments increases the likelihood of detecting corrosion by continuously recording thickness measurements as the scanning head passes over the inspection surface. The result is a scan containing wall thickness data of a 1 x 1 mm (0.04 x 0.04 in) resolution. The data can be displayed in a variety of ways. Each of these views aids in the detection and qualification of the defects. The captured thickness information can be displayed as a C-scan, an A-scan trace, a digital thickness measurement, an amplitude B-scan, or a simple-to-understand thickness profile. The most valuable display is the C-scan on which corrosion, if present, is clearly displayed and identified.

Data collection and analysis

Real-time C-scan, A-scan, and B-scan data are displayed during the scanning process. Once a scan is complete, the operator can save the scan and then analyze the results or move on to the next scan location. Scan analysis is made simple with active C-scan, A-scan, and B-scan displays; placing the cursor over any part of the B-scan window displays the corresponding A-scan trace and thickness measurement. The software also has unique features that allow the automatic sizing of identified defects. The color palette on the C-scan also allows full configuration such as areas of interest being extra highlighted. The full amplitude view helps characterize wall loss, allowing for a more detailed analysis and accurate corrosion assessment.

Reporting

The complete inspection is available for further analysis on a PC using Capture software. The software allows for post-inspection setting updates (repositioning of gates) and adjusting the data views to enhance defect recognition. Within the data analysis, functions of the software defects can be highlighted and attached with sizing information. This data is stored with the inspection data and used to provide a full and comprehensive inspection report containing both defect tabular information and graphical representations using C-scan, A-scan, and B-scan displays.

Acquisition software

Capture software embedded in Gekko portable flaw detector, and also available for PC, delivers conventional ultrasonic testing, phased array UT, but also total focusing method (TFM). Capture is intuitive and designed with an efficient workflow, providing a complete software platform that covers all inspection needs from application design to inspection and reporting. It contains application-oriented templates and supports step-by-step application design. It holds standard but customizable libraries for probes, wedges, scanners, and most common accessories. It's designed with fast and intuitive calibration wizards supporting an onboard focal law calculator for all probe configurations and techniques. Capture offers a quick way to improve knowledge and requires minimum training time for phased array inspectors.

Laser profiling solution

Considering availability and historic application within Eddyfi Technologies robotics, the peripheral tooling used for this project was the ULS-100 Laser Profiling System which has been frequently integrated with the VersaTrax™ robotic inspection crawlers. The ULS-100 is deployable in confined spaces; generates point clouds of targets such as pipes, tunnels, wells, etc., and its small form factor and short-range enables scanning in reduced access areas. High-resolution measurements coupled with short-range scans [0.13 to 1 m (0.43 to 3 ft) range] with 50° laser swath and 360° rotation gives real-time and true-scale model generation. From an operational efficiency perspective, the system boasts simple, configurable deployment and an easy-to-use interface for rapid data acquisition and most importantly, no user calibration required. The ULS-100 generates a true 3D point cloud, and data can be exported in CSV format for review by third party surveyors or in image format for reporting. It is the perfect platform to generate a 3D model of the pipeline to pin visual and UT data to.

How this unique offering stands up

Following the initial lab, then mock-up-based trials, it was clear that within a short period, we were able to produce a viable working solution based on strong technology synergies. Our job as leading technology providers and engineers is to solve the problems of our customers and clients while sometimes overcoming challenges encountered elsewhere. Challenge accepted.

In closing

The future of NDT will increasingly enable automated condition monitoring of capital assets and critical components we rely on every day. This highlights just one example of how Eddyfi Technologies’ can deliver the hottest inspection solutions for tomorrow. How can we assist you with your next job? Contact us to discuss the big challenge you’re currently faced with for a Beyond Current solution today.