We all remember the 2010 refinery disaster in Washington. We don’t need another devastating incident to be reminded of the risks of hydrogen damage. The proactive detection of HTHA helps ensure plant and worker safety as well as efficient operations across the energy sector.

The early stages of HTHA present a challenge for inspectors using conventional ultrasonic testing (UT) methods, as methane-related indications are typically much smaller than the ultrasonic wavelengths employed. It’s difficult to discriminate HTHA from unusual grain size, inclusion, surface variations or geometry; a number of anomalies can often lead to false positive results of an attack.

Advances in ultrasonic techniques has enabled technicians to characterize HTHA with leading portable units. You need to feel confident in your inspection data, and that’s why Eddyfi Technologies presents the Gekko® and TOPAZ® 64 as the trusted flaw detectors capable of Phased Array UT (PAUT), Time of Flight Diffraction (TOFD), TULA (TOFD Ultra Low Angle), Total Focusing Method (TFM), and Phase Coherence Imaging (PCI) in user-friendly instruments with intuitive software for quick setup and shorter inspection assessments. By combining these techniques, early detection of bubbles forming to produce micro-fissures at steel grain borders is now possible, and preventative measures can be recommended.

So, how exactly does Eddyfi Technologies’ portable PAUT unit detect HTHA, the defect with a reputation for being almost imperceptible?

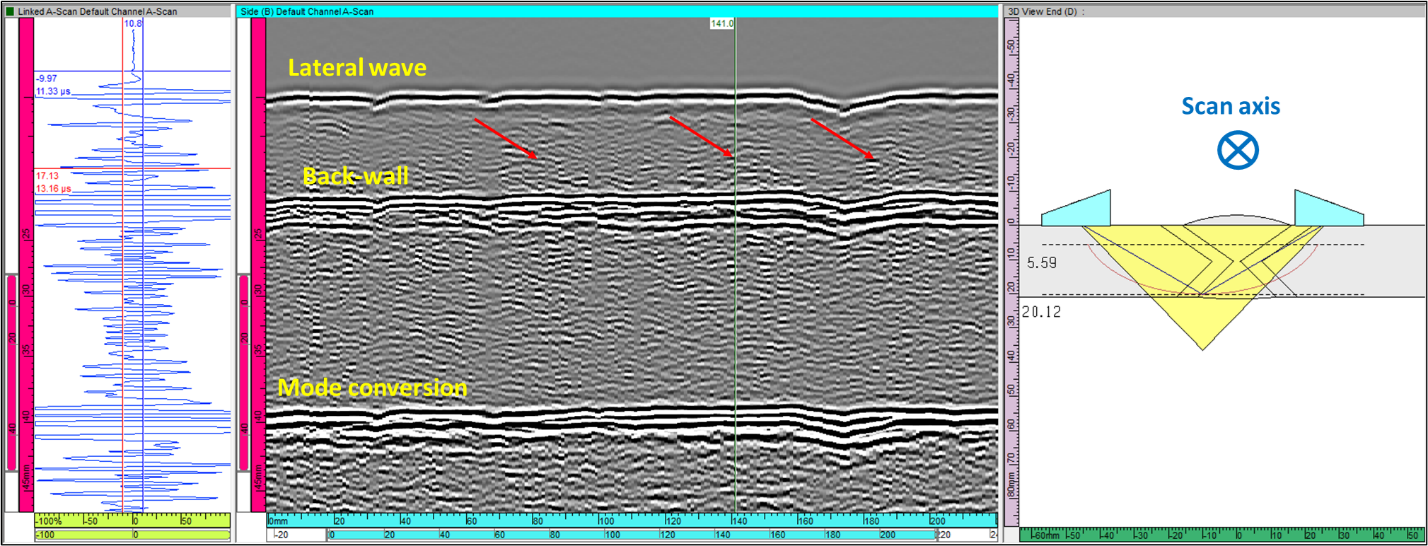

The use of high-quality TOFD probes, with piezocomposite active elements, is strongly recommended. The probe size and the frequency depend on material type and wall thickness. For thinner components, typically an inch thick (e.g. 1 inch), 10 MHz, diameter Ø 3 mm probes are very suitable. TOFD is not only overly sensitive to small discontinuities, but also quite fast. Increased grain noise (short indications) and clustering in A-scan signals are indicative for early stage HTHA.

TULA uses TRL (Transmit-Receive) probes at 10 MHz and are well suited for initial screening of thicker base material. As for TOFD, increased back-scattering and clustering in A-scan signals are indicative for HTHA.

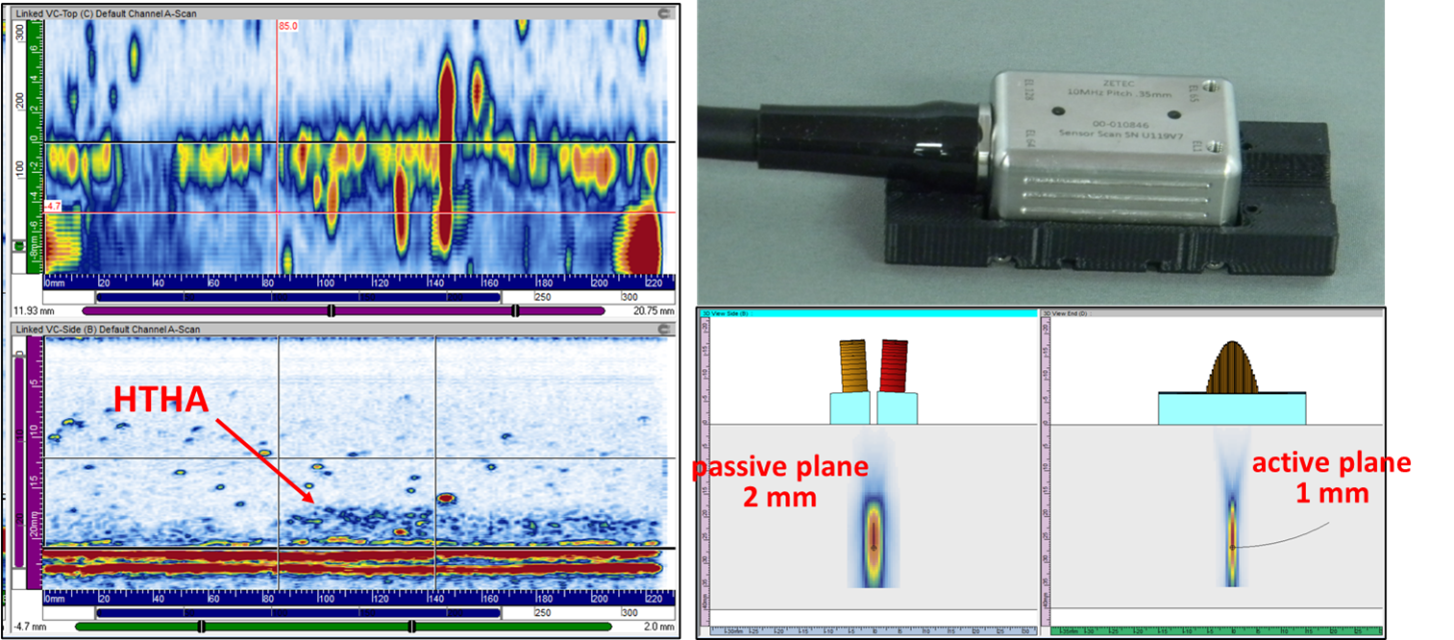

Phased array provides an image of the inspected region, in addition to the traditional A-scans, and therefore allows a more intuitive interpretation of the results. The technique allows rapid coverage of the complete examination volume by combining sectorial scanning or electronic linear scanning with a mechanical movement. And of course it provides a permanent data record for offline review and comparison with previous results. Since early stage HTHA damage generates pretty weak ultrasonic responses, the required sensitivity settings will be much higher than what is typically used for generic weld inspections after manufacturing. Eddyfi Technologies has designed a series of PAUT probes catered towards maximizing the sensitivity not only for phased-array technique, but also TFM and PCI.

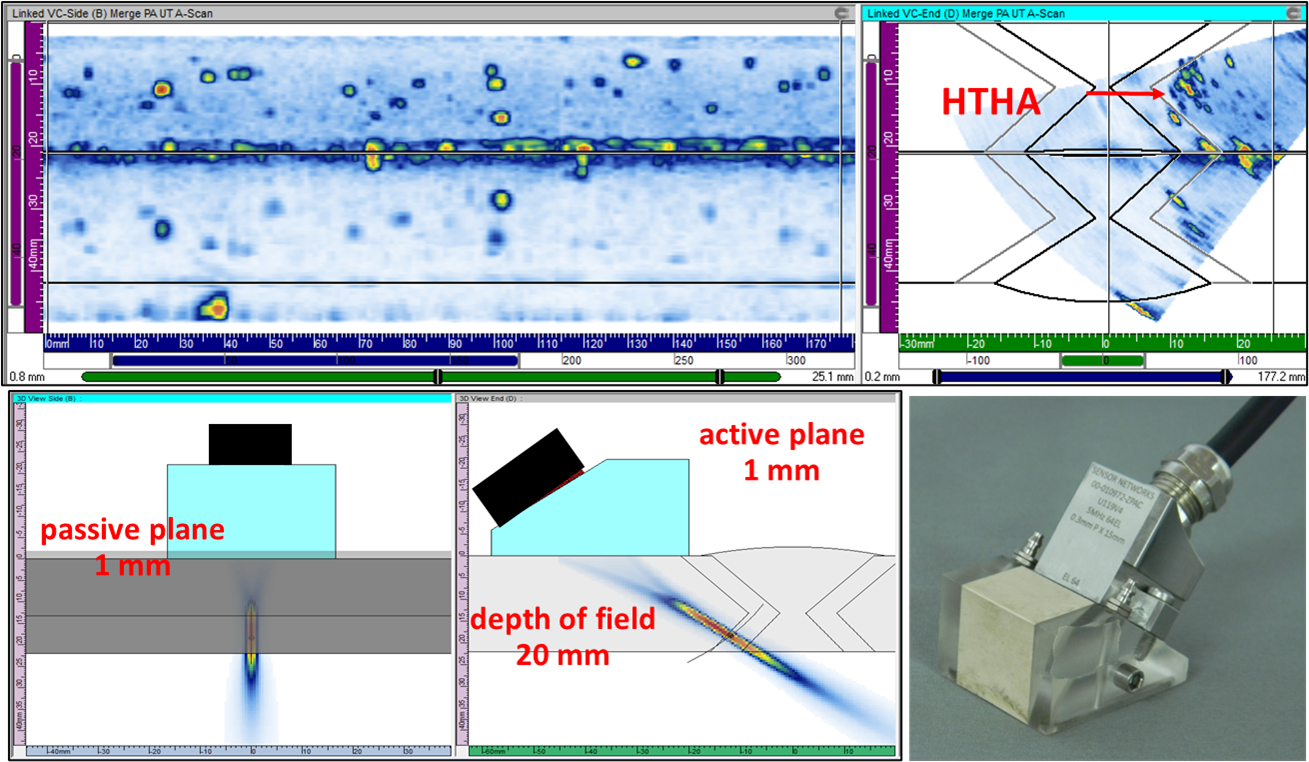

Two phased array configurations are typically used for detection and assessment of HTHA damage.

Angled beam inspection:

- A 64-element linear array with curved active elements provides a small focal beam (~1mm) along both the active and passive planes.

- It is typically used for the examination of the weld material and the heat-affected zone under a weld using a shear wave wedge. By using a focused sectorial scan, it provides a clear image of the area damaged by HTHA.

Normal incidence:

- A 2 x 64-element dual linear array (DLA) probe was designed for pitch-catch inspections. DLA probes naturally generate a focus along the passive plane where the beams intersect. Another advantage of DLA probes is the removal of wedge echoes as the emitter and receivers are separated by an acoustic barrier. This allows for shorter wedges and thus less attenuation.

- The probe is used in combination with linear scanning to look for HTHA indications in the base material or heat affected zone.

- The following image shows the size of the beam along the passive and active planes, and HTHA detected along the backwall of a component using that probe.

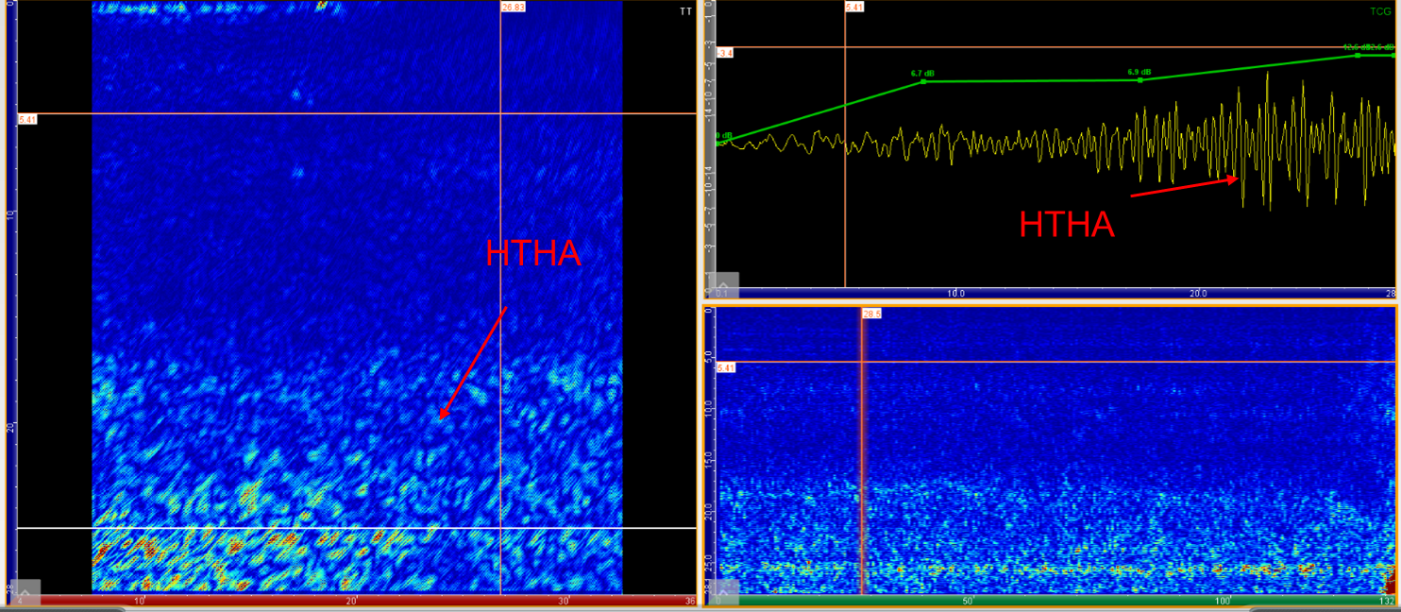

The advantage of PAUT paired with TOFD/TULA is further complemented with the additional use of TFM for the most comprehensive hydrogen damage assessment possible. The Gekko and TOPAZ contain a complete toolbox for TFM including Time Corrected Gain (TCG) calibration, and high-resolution TFM imaging with up to 128 elements. Inspectors can benefit from live interpretation of TFM frames and make assessments that ultimately help improve operations and reduce human and environmental risk by monitoring HTHA damage. The PAUT probes described before were designed to be used indiscriminately with PAUT or TFM/PCI providing improved resolution along the passive plane for all techniques. TFM/PCI focus the acoustic energy everywhere within a Region Of Interest (ROI) defined by the operator providing optimum spatial resolution along the active plane.

While resolution improves sensitivity by making the focal beam smaller, it may not be sufficient to obtain a Signal-to-Noise Ratio (SNR) good enough for detection of HTHA as the cluster of micro-cracks leads to some scattering of the acoustic energy. TFM, when obtained from an elementary FMC, fires the elements one by one sending a weak level of energy. Combined with the scattering, it is possible that nothing is returned to the probe. It is thus important to send as much energy as possible into the part. Both Gekko and TOPAZ offer Plane Wave Imaging (PWI) capability. PWI is essentially a sectorial scan using the full aperture of the array (64 elements here) combined with TFM reconstruction. The advantage is a gain in productivity as we use less angles compared to elementary FMC and more sensitivity as we fire all the elements rather than one at a time. Of course, as we are looking at amplitude data, it is necessary to perform a TCG to have an identical response no matter where the HTHA is within the ROI.

The following image shows the results (T-scan, D-scan and A-scan) obtained for a sample with stage 2 HTHA using the dedicated probe with an angled beam and shear waves. The HTHA appears as a cluster of echoes along the backwall. The amplitude is 15 dB higher than the response from the grain structure.

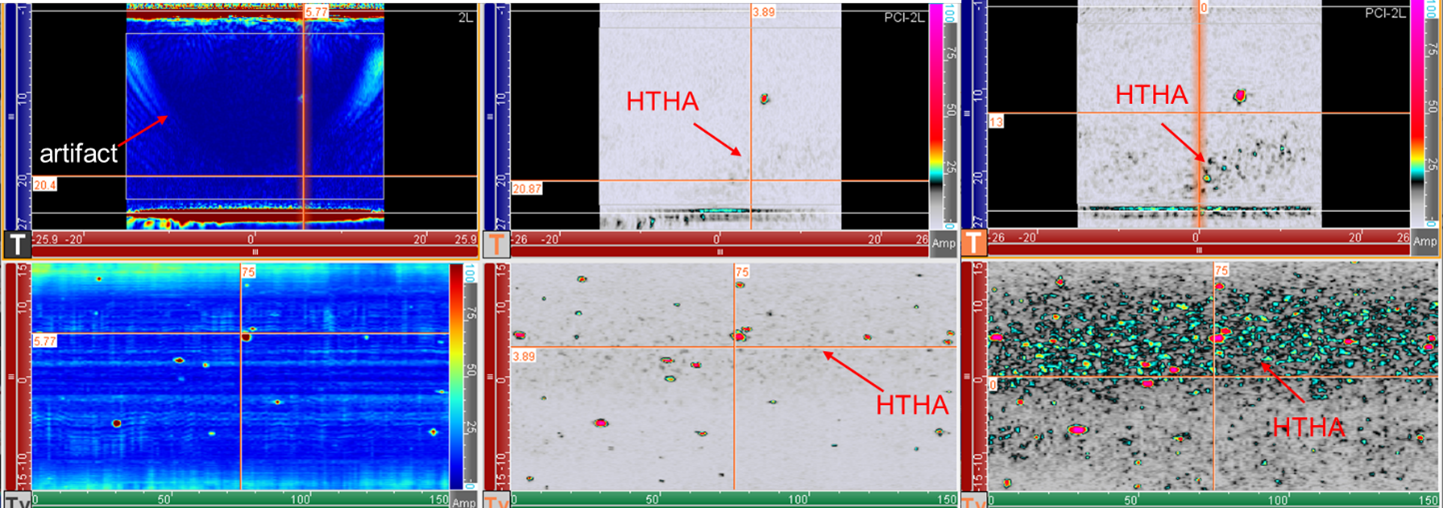

Artifacts can appear when performing TFM inspection at normal incidence, and depending on the amplitude level of those artifacts, they can prevent the detection of the HTHA microcracks. The presence of these artifacts depends on the thickness of the part, the thickness of the wedge, and the pitch of the probe. One way to remove artifacts is by using the PCI technique. PCI tends to remove or minimize all the contributions coming from specular echoes such as the artifacts in this case.

The following images show the TFM (left), PCI obtained from an elementary FMC (middle), and PCI obtained from a PWI acquisition (right). The PCI image obtained from an FMC removes the artifacts and shows tiny responses along the backwall corresponding to the HTHA damage, although the SNR is relatively weak. PCI obtained from PWI shows strong SNR and easy detection of HTHA damage while providing better productivity at the same time.

Even though PCI is a non-amplitude-based technique and the results should not depend on the level of energy sent into the part, it still requires having a non-zero SNR in the signals of the FMC matrix to extract a phase. When using an elementary FMC, the energy level is relatively weak. Combined with scattering in the cluster of micro-cracks, this leads many signals of the FMC matrix having a zero SNR and thus not contributing to the PCI image. Using PWI allows more energy to be sent into the part and thus more signals with a non-zero SNR contributing to the overall PCI image. It is thus important to have PAUT equipment that allows calculation of the TFM from a PWI acquisition like the Gekko and TOPAZ instruments.

Every day spent not really knowing the structural integrity of plant equipment and critical components is a liability that nobody can afford. And now, nobody has to. All levels of NDT technicians can take advantage of the state-of-the-art technology offered by Gekko with Capture™ software and easily detect the presence of high temperature hydrogen attack well in advance, or just in time – so you can keep your cool.

Visit the Eddyfi eStore for your one-stop PAUT shop needs including our full range of ultrasonic probes.

Contact us to learn more about Eddyfi Technologies’ advanced non-destructive testing solutions for the repeatable, actionable, meaningful and preventive data results you should expect to stay Beyond Current.