Eddyfi Technologies focuses on offering advanced NDT instrumentation for the inspection of critical components and assets through its complementary brands and product lines: Eddyfi, Inuktun, M2M, Silverwing, Teletest, and TSC. Having this diversified portfolio of NDT instruments, sensors, software, and robotic solutions helps us propose complete solutions for our customers. This article illustrates one these synergies looking at the Silverwing LYNCS™ scanner with the M2M Gekko® and Mantis™ phased array portable units directly applicable for in-service pipeline inspection and much more.

Ultrasonic inspections being weld inspection or corrosion mapping imply moving one or several probes whether conventional, time-of-flight-diffraction (TOFD) or phased array ultrasonic testing (PAUT) along the surface of a component and encoding data along one or several axes. This allows inspectors to obtain full coverage and access various views to see their data in all directions. These inspections require an ultrasonic unit capable of managing all the ultrasonic techniques, from the most basic ones (conventional) to the most exotic like total focusing method (TFM), with a scanner capable of carrying all the necessary ultrasonic probes.

Pioneering real-time TFM since 2013, Gekko is a field-proven flaw detector offering PAUT, UT, TOFD and TFM through the streamlined user interface Capture™. Released in 32:128, 64:64 or 64:128 channel configurations, Gekko combines high-resolution and speed while reducing inspectors’ training time. Gekko has since been joined later by its smaller companion, Mantis, a robust and lightweight flaw detector offering the same ultrasonic techniques on a 16:64PR architecture.

Eddyfi Technologies introduced a semiautomated scanner, LYNCS, a versatile toolless scanner that easily switches from a weld inspection to a corrosion mapping configuration for more efficient condition monitoring with a non-intrusive, or NII, approach of pipelines and other critical assets.

Combining products developed by Eddyfi Technologies’ dedicated centers of excellence provide the NDT industry with the best of all worlds.

Weld Inspection

Ultrasonic examination methods for welds are described in the various standards such as ASME V and ISO. While conventional UT is still largely used, PAUT and TOFD have quickly become the go-to technologies for both fabrication welding and in-service inspection. In addition, full matrix capture (FMC), total focusing method, plane wave imaging (PWI), and assisted defect analysis have taken advanced UT to another level.

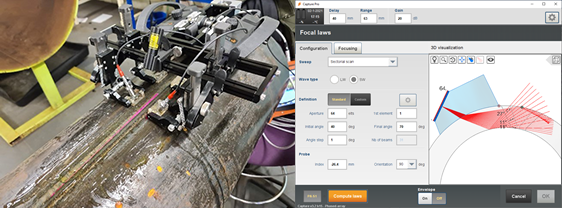

Weld inspection requires placing PAUT and/or TOFD probes at certain index offset positions to obtain full coverage of the welds. Capture allows the definition of scan plans for PAUT, TOFD and TFM helping operators define their inspection. The LYNCS WI weld inspection configuration can accommodate up to six PA and/or TOFD probes and has a dual-bar structure for enhanced stability and probe placement accuracy. It is a toolless scanner with an interchangeable design, making it ideally suited for all weld inspection configurations.

Mantis performing pipeline weld inspection using 2 PAUT and 2 TOFD probes

The following video shows a multigroup TFM inspection using two 64-L5-G3 probes with SW55 wedges held by a LYNCS in its weld configuration.

We are on the brink of releasing the LYNCS-AXIAL for the inspection of longitudinal welds. For longitudinal weld inspection, Capture offers all the tools necessary to perform complete inspections. From wedge delay calibration to delay law calculation and visual representation, operators have all the means to optimize their scan plans.

Corrosion Mapping

Corrosion mapping consists of scanning the surface of the test piece and measuring the remaining material thickness for each position. It can be done using a conventional ultrasonic testing or phased array probe.

The LYNCS CM corrosion mapping arrangement is ideally suited for vessel and pipework inspection. It has an extremely low profile and lightweight design, making it the most suitable option for rope access deployment and heavily congested pipework. It can utilize both probes with a hard wedge but also a water-column concept which eliminates the need for a wedge, thus providing the benefits of improved signal consistency, accuracy, and limited dead zone. This offers enhanced surface conformance and improved coupling.

Capture provides gate synchronization, interface echo straightening and synchronized time corrected gain (TCG) to allow for smooth corrosion mapping inspections. With a pulse repetition frequency (PRF) of up to 20 kHz and 40 kHz, respectively, the Mantis and Gekko offer scan speeds of over several hundred mm/s providing optimum productivity. The 16-dB dynamic range ensures that the peak amplitudes are measured despite an apparent echo saturation on screen.

The following video shows the LYNCS CM and the Mantis in action.

Advanced data analysis is available on all Eddyfi Technologies PAUT units starting with the entry model Mantis. A stitching tool merges various 2D mapping inspections and auto-sizing quickly and automatically creates a table of indications to help operators improve the productivity of their inspection.

Both the modularity of scanners and integration with Capture software enable operators to easily setup their inspections effortlessly and stay Beyond Current. By exploiting the synergies between complementary product lines, Eddyfi Technologies offers unmatched advanced solutions for technicians. Start benefiting from our diverse range of in-house expertise and contact us to discuss a better solution for your integrity assessments today!