The right scanning speed depends on the PRF of the equipment, the soundpath of the ultrasound and the amount of data that the inspector is trying to acquire. Scanning too fast can lead to missing data.

Usually, missing data is seen easily on C-scan or D-scan as vertical black lines but what happened when the scanning length is longer than the resolution of the screen? A 42-inch weld with data every single millimeter can lead to more than 3000 mechanical positions, a 10.4-inch screen has typically a 1024 resolution.

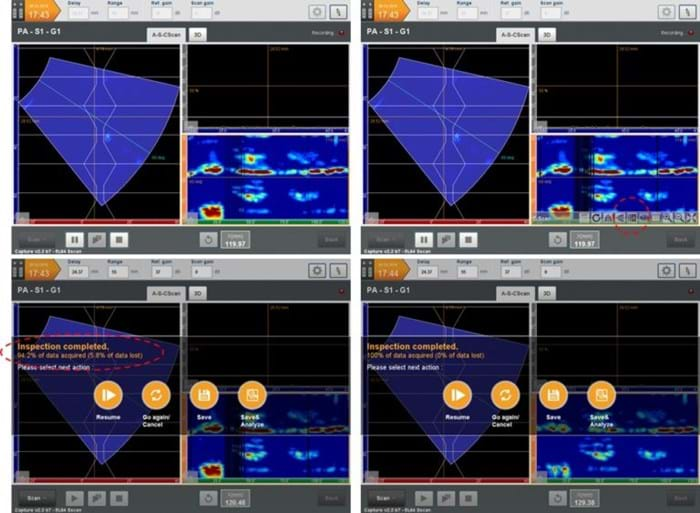

The 2.3 version of Capture™ data acquisition and analysis software now offers new tools to make sure that data is not missed. In the top left picture, you can see that some lines are missing. When we turn on the "missing frames" tool, we see that more frames were actually missed (top right image). At the end of the scan, the software gives the percentage of acquired data and frames missed, in this case 5.8% of the data were missed. This allows the operators to go back and scan the missing areas to make sure that 100% of inspection is done.

See how our evolutive data acquisition and analysis software continues to keep users Beyond Current here, and get in touch with our team to discuss optimizing your next inspection campaign.