The TSC Amigo™ and TSC U31™ series have reached their end of life; more details can be found here. With 20-year-old technology that revolutionized surface-breaking crack detection for subsea and offshore applications being retired, we embrace the next generation instruments that continue to push the limits of Non-Destructive Testing (NDT) forward.

Alternating Current Field Measurement (ACFM®) was borne from the need to detect fatigue cracks with better results than what magnetic particle inspection and conventional eddy current testing systems available in the 1980s offered. Because the depth of these cracks indicates the remaining useful life of critical assets, it is vital to have trustworthy data. Alternating Current Potential Drop (ACPD) was used to measure the depth of fatigue cracking, but the technique wasn’t ideal for underwater applications. ACFM has since proven to be the superior NDT technique for surface crack inspection in topside and offshore installations. The method —which removed the need for good electrical contact between voltage probe and steel surface— measures two components of magnetic flux density to reliably size a defect’s length and depth. Discover how ACFM changed the subsea crack detection game here.

While underwater performance is a distinct advantage of ACFM, the technique’s ability to inspect through paint and coatings is invaluable. With the offshore atmosphere featuring heavy salt concentrations from spray, being able to inspect through the protective layers in place is a game changer. The next generation ACFM instruments offered by Eddyfi Technologies enables detailed assessment through layers as thick as five millimeters (or 0.2 inches) with the ability to report surface-breaking cracks up to 25 millimeters (or one inch) deep.

Widely accepted by offshore oil and gas stakeholders, ACFM has also been successfully employed for land-based operations including in-service tank and vessel inspections at process plants. Beyond the energy sector, freight transporters regularly use Alternating Current Field Measurement to help ensure safe operations. Learn about the rolling momentum of ACFM in the rail industry here. And though this technique has the highest sensitivity on ferromagnetic materials, ACFM has also been applied to titanium risers, Inconel threaded connections on downhole motors, and even austenitic stainless steel nuclear storage tank pools - all with positive results.

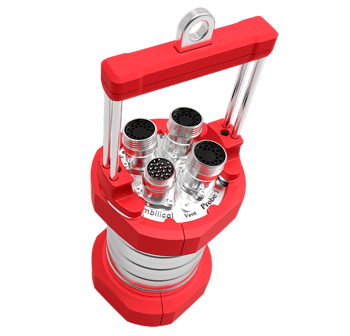

Recognized as being user friendly, reliable and rugged, the original Amigo ACFM instrument has successfully matured to the TSC Amigo 2 which offers even better speed, signal quality and portability. Similarly, the TSC U41 has modernized subsea ACFM. It is more than 10 times faster than the U31 product offering (compare the models here). The next generation ACFM inspection solutions by Eddyfi Technologies keeps inspectors Beyond Current. Request more information from our experts today.

.png)