Remote-field testing (RFT) and remote-field array (RFA) inspection results are especially sensitive to speed. It is particularly important when using this technique to have as much of an accurate maximum pulling speed as possible.

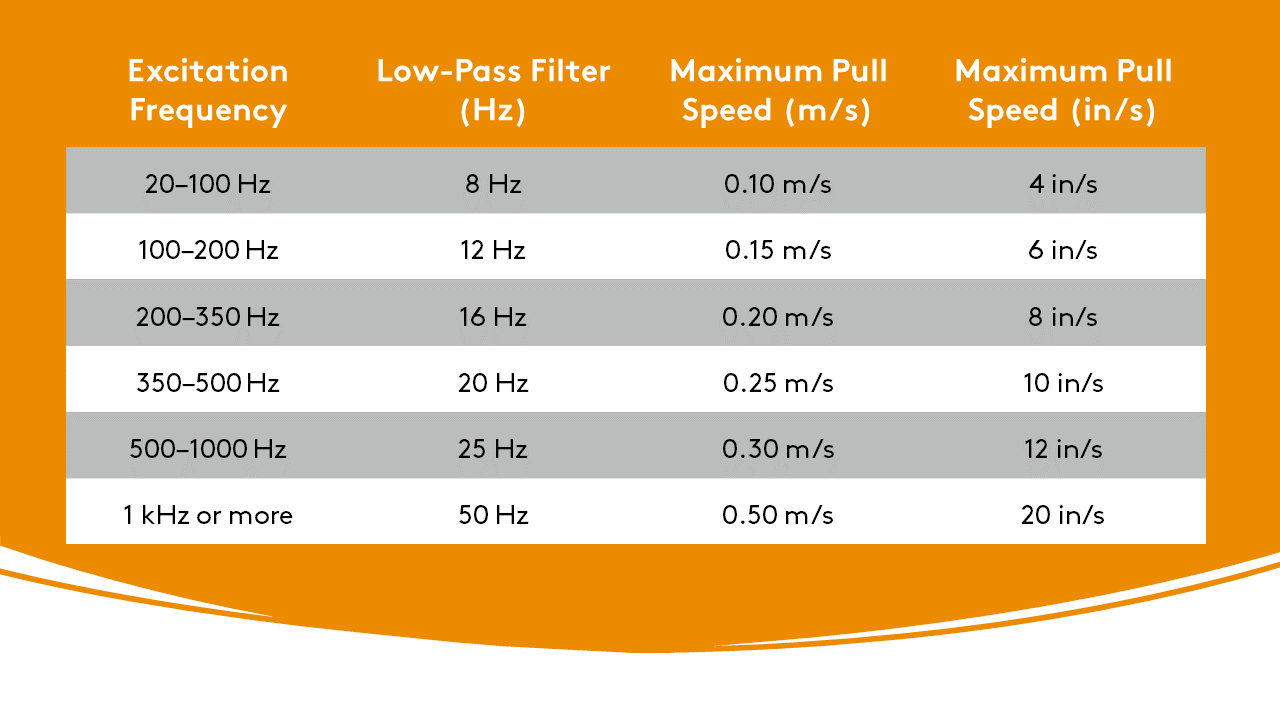

The probe’s excitation frequency dictates what low-pass filter is applied to inspection data to lower noise. The frequency of the low-pass filter is directly proportional to the maximum inspection speed.

Simply put, the lower the excitation frequency, the higher the noise from the utility frequency (50 Hz or 60 Hz power outlet). The higher the noise, the tighter the low-pass filter (lower frequency) around the excitation frequency of the probe. Consequently, the tighter low-pass filter can eliminate high-frequency signals. This calls for a lower inspection speed to reduce the defect’s signal frequency.

To rigorously ascertain the maximum RFT inspection speed, you must consider three variables:

- Target defect size

- Receiver coil physical size (varies according to probe design)

- Instrument bandwidth/low-pass frequency

Here’s a maximum pulling speed cheat sheet you should bookmark for later, based on 4-millimeter (0.158-inch) defects, a typical RFT probe, and 25.4-millimeter (1-inch) tubing.

Now imagine perfecting the tube pulling tempo and not using the most trusted probes commercially available... take a look at our RFT single-driver probes, RFT double-driver probes, RFT single-driver flexible probes, RFT double-receivers, RFT single-driver boiler probes, and RFA probe . Or, you can just use our tubing probe creator to discover which tube testing probe is best suited for your specific application.

Don’t miss these additional resources:

- This Coffee Break with Eddyfi Technologies offers a closer look at the Ectane® 3 inspection instrument and our RFA technology.

- This application note shows how the Probot™ may just be your next best friend, helping you achieve maximum inspection speed with a remote-field probe for testing carbon steel tubing.

Take your tube testing inspections to the next level (no ladder required); contact our team of experts to discuss how best to implement Eddyfi Technologies’ remote-field testing technology into your operations today!