Time-of-Flight Diffraction (TOFD) is an ultrasonic testing technique that has been around for more than 40 years. It is a fast and reliable method to detect, locate and size indications. The technique is based on diffraction and reflection, making it less sensitive to defect orientation and therefore a great technique for the rapid testing of circumferential and longitudinal welds.

TOFD has been part of the Capture™ arsenal since day one. With the release of Capture 3.1.1, TOFD benefits from an analog gain of 19 dB for an even better Signal-to-Noise Ratio (SNR).

In a TOFD configuration, a pair of angle beam probes are used on opposite sides of a weld, one acting as a transmitter and the one as a receiver. The energy spreads over a wide angle and can be picked up from almost anywhere along the surface of a structure. Defect detection is based on measurements of time differences between diffracted signals from the extremities of a defect. Since diffracted signals are usually relatively low amplitude, TOFD requires probes with high sensitivity and high bandwidth and systems with good signal quality.

The release of the 3.1.1 version of Capture software offers a 19 dB analog gain boost to all M2M Gekko® and M2M Mantis™ instruments, improving the SNR of TOFD inspections. There’s no need to send your equipment back - just update Capture and immediately enjoy the benefits.

TOFD has been part of Capture since its first release, just like Phased Array Ultrasonic Testing (PAUT) and Total Focusing Method (TFM); it provides calibration and analysis assistants to help operators perform their TOFD inspections.

The Probe Center Separation or PCS is easily estimated by using the arrival time of the lateral wave and/or backwall echo as shown in the following video. The TOFD scale is then displayed in millimeters (or inches). This tool is also available when only the lateral wave or backwall echo is available.

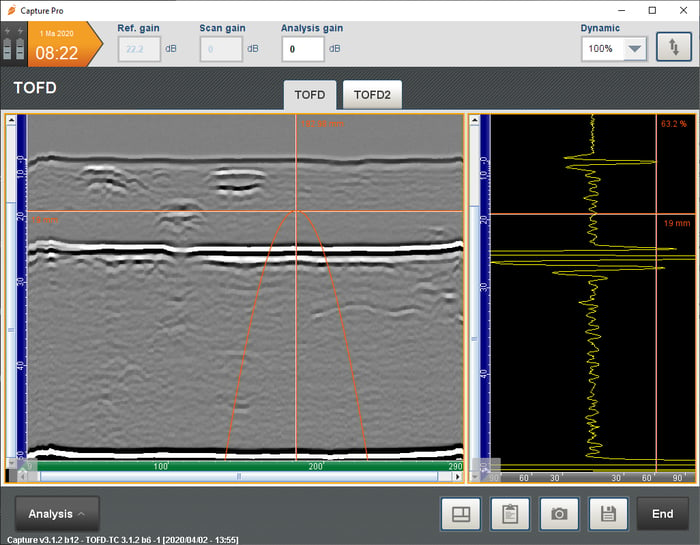

The following image shows the TOFD signal obtained with version 3.1.1 of Capture, without any filter or averaging, for a pair of 5 MHz Ø6mm L70 TOFD probes on a 25mm V weld (1in); PCS is 95mm to have the beams cross 2/3 through the test piece. Of course, operators can apply filters (low, high, and bandpass), choose the cut-off frequencies they want, and average up to 32 times if noise becomes an issue.

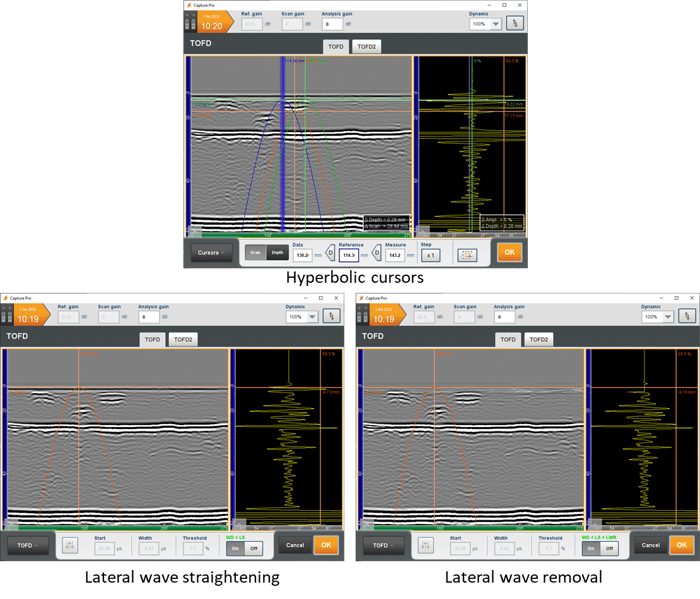

All the analysis tools are available: wedge delay, hyperbolic cursors, lateral wave straightening and removal, and delta cursor to measure the difference in depth/height within the B-Scan display. The following images show some of these tools.

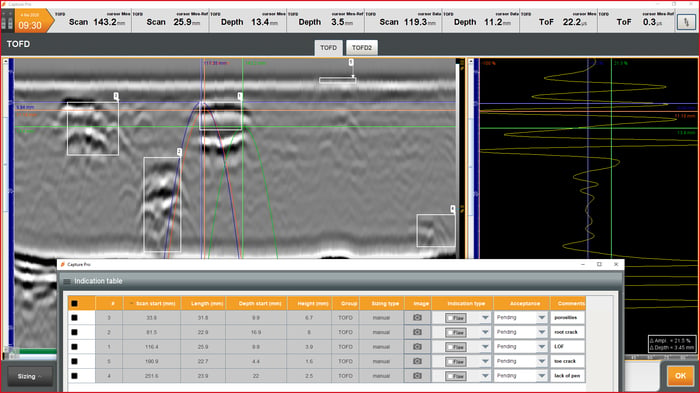

The hyperbolic cursors are available with the three-cursor tool allowing operators to measure the length and size of indications and send them directly to a table of indications. The table of indications has also been revised with the new analysis tools with a template for TOFD for operators to report the indications more easily. The table of indications is customizable.

The banner of indicators at the top of the screen has been redesigned to offer more information. It is also completely customizable, and templates can be created for operators to conveniently load their favorite indicators.

The Gekko comes with two pairs of conventional TOFD channels. It is possible to use an accessory to take some of the PAUT channels for TOFD, allowing up to four pairs of TOFD for very thick materials. The Mantis has one pair of TOFD and can also use the same accessory. Both units can combine TOFD with PAUT inspection in a multi-group configuration.

The continuously improving features offered by Capture software keeps inspectors Beyond Current. Contact us to learn more about the Gekko and Mantis for your TOFD inspections today.