As NDT technology continues to grow, accelerate and change ultrasonic testing, service providers must be agile to remain relevant in today’s fast paced world. Welding inspectors recognize that time is money; they require the highest performance tools to produce reliable and repeatable volumetric data collection results. At the end of the day, you’re compelled to deliver a welding defect inspection report faster than the other guys with absolute confidence in your assessment.

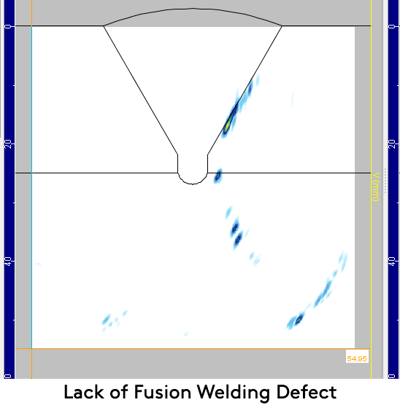

With Full Matrix Capture (FMC), A-Scan signals are recorded from every transmit-receive combination for a phased array transducer. This comprehensive dataset makes it possible to create UT imagery for any given beam and is ideal for post-processing analysis techniques. The Total Focusing Method (TFM) exploits this data to build a grid of pixels where each pixel is calculated using a dedicated focused focal law. The granularity of the grid is enhanced to produce a clear image based on the transit time between each element and each pixel. Technicians must confirm that the resolution quality guarantees amplitude fidelity as both ASME and IIW Standards regulate the use of TFM for weld inspection.

When it comes to hardware, more active channels not only ensure superior data quality, they also ensure faster pulsing (no more missed data). Moreover, compared to flaw detectors that multiplex 32 channels, the 64-channel parallel architecture of the Gekko® make it twice as fast – before considering the additional Capture™ software optimization tools. Compared to earlier versions, the software ensures increased TFM speed between 3 and 30 times faster. In addition, the Gekko is the only available instrument offering TFM with up to 128 channels. It increases productivity without slowing down your TFM weld inspection; it can scan up to 4in/second for a compliant setup of a 1.0in thick V-prep weld inspection, and up to 13in/second for a 0.5in thick V-prep weld inspection.

Inspectors can quickly characterize defects, even in thicker welds, with certainty thanks to the TFM high resolution. It is the only unit that offers all calibration wizards including Time Corrected Gain (TCG) in TFM, also mandatory for inspection procedures. Learn how to simplify weld inspection using TFM in our webinar found here. Finish first and stay Beyond Current by taking advantage of the field proven Gekko TFM flaw detector for weld inspection and other assessments that demand the most reliable data processed in the shortest amount of time. Contact us today to discuss optimizing your next inspection campaign.

.png)