Thanks for joining today, Francis. To give our readers a little background, can you tell us what drew you to non-destructive testing?

I studied physics engineering around 2000, and at the time, Sebastien Savard – an Eddyfi Technologies employee who was working at R/D Tech – came and gave a presentation when I was a student. My major in university was material science. During my studies, I grew interested in the possibilities of R/D Tech. This is when I began thinking about starting a career in NDT. Soon after I was out of school there was a job opening, I was invited to apply, and this is how I got started.

Since then, I have always stayed in NDT. For the last 15 years, I have had the chance to travel the world (well not for a year now under the given circumstances). I have been onsite a lot, so I have a good mix of theory and hands-on experience. I had the chance to work for different NDT service or product companies in the Quebec City area. I have now been working at Nucleom for 10 years.

What do you enjoy most as Lead Engineer at Nucleom?

The technical side of NDT and the number of different industries you serve keeps things interesting. I have the chance to work with aerospace, oil and gas, construction and more so you can touch a lot of good technology. I like my role because I am involved with a lot of projects at Nucleom, not just one. Not that many people know about NDT, and when people ask what I do, a good analogy is that we diagnose industrial parts such as a doctor would for a broken bone.

That’s a good way to put it! So, I understand Nucleom uses quite a few different Eddyfi Technologies solutions... everything from the Floormap to the Ectane and Reddy. Can you speak to why Nucleom chose Eddyfi Technologies for their advanced inspection solutions?

The fact that Nucleom and Eddyfi’s business roots are similar favors our current long-lasting relationship. Quebec City is one of the biggest NDT hubs in North America. This allowed for continuous cooperation between different players in this sector throughout their years of experience. Not only is there the trust in the technology and projects that Eddyfi offers, but there is also a high confidence level. We like to define ourselves as a high-technology company and Eddyfi Technologies offers quality, high tech products.

That’s great feedback. I understand that the Eddyfi Sharck probe featuring TECA technology is among the NDT toolbox for Nucleom. Can you offer a good example of an application where this probe is used?

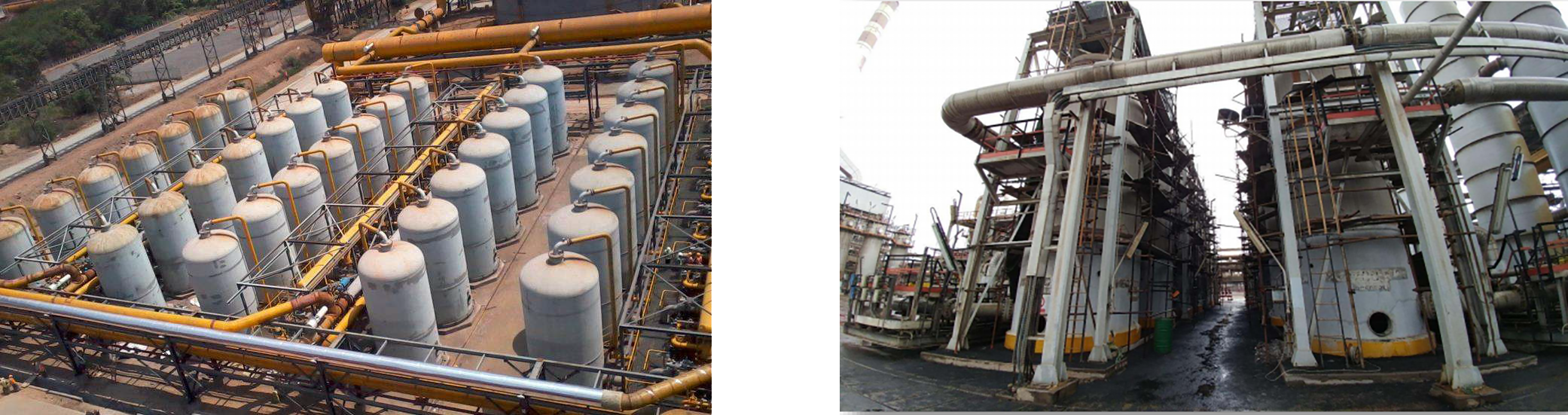

Of course. We have a broad range of applications, so I will focus on weld applications today. There was a cool project in the Middle East where we used the Sharck probe specifically for pressure swing adsorption vessels or PSAs. A PSA is basically a tank and because of the function of that tank, there is a cycle that puts a strain on the welds. Over time, these welds can develop cracking while in service. For this job, there was a lot of tanks requiring weld inspection, and the Sharck was perfect for recording everything and doing all the components for the client. We were able to cover the full scope of the inspection campaign that included circumferential head weld, circumferential body weld and longitudinal weld by combining the Sharck Butt Weld and the Sharck Pen capabilities.

Pressure Swing Adsorption Vessels (PSAs)

Good point. So, you’ve started to answer why you’d use the Sharck over more conventional techniques like MPI. Are there any environmental issues that come into play?

There are a few environmental factors to take under consideration. In the case of the Middle East inspection, being outdoors with sand in the wind makes a magnetic particle testing (MT) inspection more challenging. Even at home in Quebec City, where there’s wind without sand, it can be a challenge: you throw powder and then it goes with the wind – it can be done but it is more difficult so when you think about when there are other components in the air, you can imagine how much more difficult this becomes.

The cold is another factor that increases the difficulty of MT. If we were asked to do an inspection in winter conditions, Sharck would be a good choice because of the below freezing point. You do not have to manipulate power, and it probably would not be possible with the black and white technique (MT). All this is impacted by the surface condition. While you still need good surface preparation for the Sharck technology, it has an edge over MT.

Then back to your comment about the environment, being able to reach areas in scaffolding or in a harness with MT, I have seen guys doing it, but it is very inconvenient. You need to throw your powder and have two hands near the component but with the Sharck probe, you can be stable by reaching with your arm extended.

What would say then was the main driver for selecting the Sharck to inspect the many pressure swing absorption vessel carbon steel welds?

The main advantage is a faster inspection offered by Sharck. Going back to the example in the Middle East, there were many components or welds to inspect that it would not have been practical to have 100 percent weld inspection by conventional methods. This equipment often needs to be inspected during a shutdown, which means stopping production. This represents an added cost for the client. The advantage of the Sharck was being able to do the inspection in the planned time frame. We were able to inspect the 12 pressure vessels in a short amount of time. This being said, I would expect that using the MT would have taken more time.

Another point is the probability of detection and the precision of sizing that are better with the Sharck. There is also a better control over human factors when compared to MT. For MT, the technician needs to focus on what he is doing the entire time but with the Sharck, he can use the data recording capabilities and follow-up with a post-acquisition analysis.

I can tell you, from all inspection projects I have been involved with, reducing human factors is an important aspect to perform a quality job/project. An interesting parallel between MT or similar techniques and driving a car is that you need to try to have an attention span near 100% but it is not possible. Different factors like fatigue, scanning a large surface versus driving a long distance, environmental factors and technician/driver skills and experience will impact the inspection. Translate this to NDT and it will reduce the probability of detection for indications. But with the Sharck solution, the data recording capability becomes an advantage over MPI by removing most of the human factor during acquisition. It allows the possibility of having somebody else reviewing the data to support and confirm, if necessary, calls taken in the field. Finally, it brings a better data traceability, especially useful for future inspections.

Sharck Butt Weld probe being deployed on PSA welds

You touched on how the Middle East job had many vessels and for these bigger inspection jobs, the Sharck is ideal because it’s faster than MPI. Could you compare the time spent here or against a single element probe?

The Sharck or Eddy Current Array (ECA) offers large coverage, for applications with a large surface, more quantities, or length, it will help to have array technology available. The welds from the Middle East application were really large. Not all welds are like that, it depends on the thickness of the component: the thicker the component, the larger the weld tends to be. When you have an array, you can do a single scan. When you consider it takes three to four scans with a single element probe, an array saves four times the work. That does not count calibration and setting up the equipment and all that.

Sharck can naturally replace magnetic particle but also penetrant testing (PT). PT is messy and requires a lot of consumable goods. From the service company’s point of view, the added value of services over MT or dye penetrant testing given how fast Sharck is, and all benefits discussed, there is a good business case. The asset owner also benefits. You can squeeze inspections in shorter windows of time, this translates to less production stoppage, and cost savings.

Large welds on PSA being inspected in a single pass with a Sharck Butt Weld probe

It’s only fair that if we talk about the highlights that I also ask if there any drawbacks to the technology.

If we talk about challenges by the technology itself, one thing is that it does require specific training for technicians. Such advanced training for ECA technology is generally only offered by OEM’s because most NDT training centers are not covering it yet. Their focus remains on basic EC courses, e.g., conventional bobbin for tubes inspections, pencil probes for cracks detection, encircling coils for rivets inspection for the aeronautic, etc. so advanced ECA solutions like Sharck products are not usually being covered. Thus, there is no official certification for this technology. However, Nucleom developed a specific internal SNT-TC-A1 certification program to certify our technicians.

On the topic of being comfortable with the technology, can you speak to the quality of the data output for tangential eddy current array inspections with the Sharck?

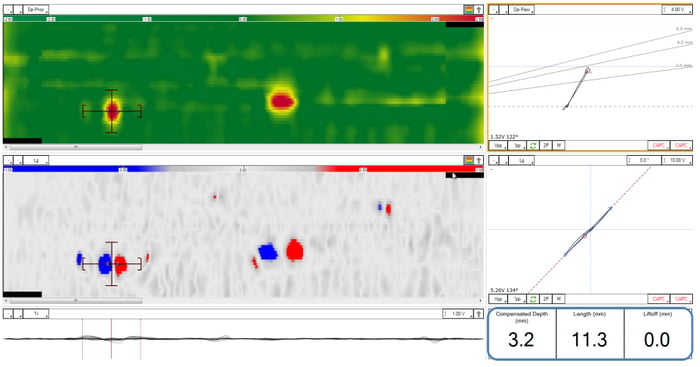

The C-Scan image capabilities of the Sharck array are very interesting. The software offers differentiation of signals for axial and circumferential indications. You can differentiate and above all, characterize the different indications. A technical manager or anyone with a basic training could understand the signal response. If you show the signals from a calibration block, an asset owner or manager will understand what he is looking at. In NDT in general, that is why we calibrate, to have a basic pattern when the material is good. The readings are interpreted by a human and further characterized.

Magnifi® software interface offers easy-to-interpret C-Scan views and assisted analysis for crack depth and length sizing

The next step is to have machine learning or artificial intelligence over what the technician can interpret. In the short term, it will help increase confidence of the technician, and in the long term, it will greatly increase the human productivity for data analysis.

One day soon, Eddyfi Technologies is always pushing the limits of NDT forward! Going a bit broader here, what advice would you offer to those that depend on non-destructive testing to make important business decisions?

Like you said, it is a large question. When the economy is good, there is a lot of manufacturing and fabrication. For many manufacturing applications or new fabrication, it is important to have good NDT capabilities or incorporate NDT into the quality control process for good components. NDT must be seen as an investment in prevention. In some cases, the components can have an extended life. NDT allows for the optimization of material lifespan in a safe way. Ensuring the reliability of these NDT processes becomes a priority and can literally save lives.

To end things off, what is important for our readers to know about Nucleom?

Nucleom uses advanced technologies. Through our engineering team, innovation is pushed forward in the optimization process of our services for field applications. If you are thinking about going for an eddy current inspection, Nucleom offers high-quality service. We like to be innovative and another key point that not all other companies have is that we can combine advantages of various technologies: we are not only good at eddy current but many different technologies. We are developing parallel services like welding engineering and 3D scanning capabilities, fitness-for-service services and so on, so we can offer an inspection campaign around the NDT needs of a client. We are a solution-oriented and proactive team, and we are passionate about our jobs!

Well on behalf of our readers, thanks for sharing your expertise with us today Francis!

For those interested in learning more about Nucleom, visit their website here, and if you’re interested in leveraging Eddyfi Technologies advanced inspection technologies to stay Beyond Current, get in touch with our experts today.

Thanks for joining today, Francis. To give our readers a little background, can you tell us what drew you to non-destructive testing?

I studied physics engineering around 2000, and at the time, Sebastien Savard – an Eddyfi Technologies employee who was working at R/D Tech then – came and gave a presentation while I was a student. I was already majoring in material science, so I found what R/D Tech was doing very interesting and always thought that I could have a career in NDT. The first year out of school there was an opening, I was invited to join, and that’s how I got started.

Since then, I’ve always stayed in NDT. For the last 20 years, I’ve had the chance to travel the world (well not for a year now under the given circumstances). I have been onsite a lot, so I have a good mix of theory and hands-on experience as well. Having worked a couple of times with Olympus, I then took a position in a small service company startup in Quebec City. I left roughly 10 years ago and formed a company with my brothers; it was not so big at that time but then we merged. It has now been five years this year at Nucleom.

What do you enjoy most as Lead Engineer at Nucleom?

I just finished a management degree last year, and I do like management, but what I enjoy most is the technical side of NDT. The number of different industries you serve keeps things interesting. For example, I have a good friend who works in an aluminum plant, so he’s doing that all the time. For me, I work with aerospace, oil and gas, construction and more so you can touch a lot of good technology. I like my role because I am involved with a lot of projects at Nucleom, not just one. Not that many people know this field, and when people ask what I do, I say I’m a doctor but for industrial parts.

That’s a good way to put it! So, I understand Nucleom uses quite a few different Eddyfi Technologies solutions... everything from the Floormap to the Ectane and Reddy. Can you speak to why Nucleom chose Eddyfi Technologies for their advanced inspection solutions?

First of all, we have a deep relationship beyond the business connection. Our historical roots include Martin Theriault, the CEO of Eddyfi NDT, being my boss’s CEO early in their careers. There’s a lot of people between our two groups who have known each other at different phases of our careers. Not only is there the trust in the technology and projects that Eddyfi offers, but there is also a high confidence level. For Nucleom, there’s a comparative advantage of other similar companies, and to be honest, Eddyfi is really proactive. We like to define ourselves as a high technology company and Eddyfi Technologies offers good, high tech products, so right there, even if we did not have a deep connection, I think we would still use Eddyfi Technologies’ solutions.

That’s great feedback. I understand that the Eddyfi Sharck probe featuring TECA technology is among the NDT toolbox for Nucleom. Can you offer a good example of an application where this probe is used?

Yes, for sure. We have a broad range of applications, so I’ll focus on weld applications today. There was a cool project in the Middle East where we used the Sharck probe specifically for pressure swing adsorption vessels, or PSAs. A PSA is basically a tank and because of the function of that tank, there’s a cycle that puts strain on the welds. Over time, these welds can develop cracking while in service. For this job, there was a lot of tanks requiring weld inspection, and the Sharck was perfect for recording everything and doing all the components for the client. In particular, there were some areas where you had a circumferential and an axial weld crossing in a dead zone that was overcome with use of the Sharck.

We also use the Sharck often in the Montreal area where we have an office and do a lot of refinery and oil and gas industry inspections. We use it almost every week. We’ll still do conventional techniques like Magnetic Particle Inspection, or MPI/MT, but we complement these kinds of inspections with the Sharck. When you take something with MT, you don’t have a sizing capability, so if an indication is detected, it can be confirmed with the Sharck probe. There can be an area where the yolk isn’t good for detection, so we directly use the Sharck probe because the tip is smaller, and we can reach confined or difficult-to-access areas. By definition with MT, you need to look at how the component looks to see the powder, but because you can reach with the Sharck probe and look at your instrument screen instead, you’re offered some advantages especially when looking directly at a component in a dark area or behind something that you can’t directly see.

Good point. So, you’ve started to answer why you’d use the Sharck over more conventional techniques like MPI, and it sounds like access is obviously a factor for obtaining that recordable result.

There are a few environmental factors. In the case of the Middle East inspection, being outdoors with sand in the wind makes an MT inspection really difficult. Even at home in Quebec City where there’s wind without sand, it can be a challenge: you throw powder and then it goes to the wind – it can be done but it’s more difficult so when you think about when there’s stuff in the air, you can imagine how much more difficult this becomes.

Cold is another factor that makes MT difficult. If we were asked to do an inspection in winter conditions, Sharck would be a good choice because of the below freezing point. You don’t have to manipulate power, and it probably wouldn’t be possible with a black and white technique anyway. All this is related to the surface condition also. While you still need good surface preparation for the Sharck technology, it has an edge over MT.

Then back to you comment about access, being able to reach areas in scaffolding or in a harness with MT, I’ve seen guys doing it, but it’s very inconvenient. You need to throw your powder and have two hands near the component but with the Sharck probe, you can be really stable reach with your arm extended.

What would say then was the main driver for selecting the Sharck to inspect the many pressure swing adsorption vessel carbon steel welds?

The main factor is a faster inspection offered by Sharck. Thinking of the example in the Middle East, there were so many components or welds to inspect that it would not have been practical to have a 100 percent weld inspection by conventional methods. This equipment often needs to be inspected during a shutdown which means stopping production when stopping their usage, so for the client it’s not only a cost to inspect but they’re also losing money with the equipment stopped. So, the advantage of the Sharck was being able to do 100 percent of the inspection in the allowed time window.

Another point is the probability of detection and the probability of sizing are better than MT because MT is human based. The technician needs to stay attentive to what he’s doing the entire time. I can tell you having been in the industry for years and it’s just human law -even when you drive your car- I think the attention span is like 98-99% on average, but there’s still one or two percent that you don’t pay enough attention to the road. It’s the same thing for MT. Even good technicians cannot pay attention 100% of the time, so it reduces the probability of detection for indications. With the Sharck probe, you don’t encounter that since you’re recording everything that you can check later. You can perform a quality review because the inspection is recorded, and your detection and sizing accuracy are higher on average.

Anyway, a technician deploying the Sharck probe will be competent with MT, so we’ll have a yolk in case of standards, sometimes. There’s a human relation over technical aspect as well where you’ll have a manager think we’re performing black magic, but when you have an MT inspection, you can directly see the powder conglomerate around a crack to prove what you’re finding, so the point is that we can have MT as a backup for different reasons when we do a campaign.

You touched on how the Middle East job had many vessels and for these bigger inspection jobs, the Sharck is ideal because it’s faster than MPI. Could you compare the time spent here or against a single element probe?

The Sharck or Eddy Current Array (ECA) in general offers a bigger paintbrush, so for applications with large surface, more quantities, or length, it will definitely help to have array technology available. The welds from the Middle East application were really large. Not all welds are like that, it depends on the thickness of the component: the thicker the component, the larger the weld tends to be. When you have an array, you can do a single scan. When you consider it takes three to four scans with a single probe, an array saves four times the work. That doesn’t even count calibration and setting up the equipment and all like that.

Sharck can naturally replace magnetic particle but also penetrant testing. Penetrant testing is dirty and requires a lot of consumables. From the service company’s point of view, the added value of services over MT or dye penetrant testing given how fast Sharck is and all benefits discussed, there is a really good business case. The asset owner benefits too. You can squeeze inspections in shorter windows, there’s less production stoppage, and cost savings all around.

We partnered with Eddyfi Technologies on another big project where the asset owner built a pipe section simulating real conditions, and just to give you an idea, they invested half a million dollars to build four different pipe configuration components. There were a lot of different artificial defects, and we were able to use it for external cracking or external detection. We did a full body inspection with the Sharck HR probe. That’s where we have comparative numbers. It was faster using the Sharck HR rather than doing a full MT. The same would apply for weld inspection. For example, on these pipes, there were ERW welds, and we did a specific scan with the Sharck for them that was harder and slower with MT. On top of having the recorded data, we benefited from the higher probability of detection again.

When talking about technologies in combination over replacement, and maybe less related to welds, we’ve done a few large scope projects. There was one nuclear application where we combined UT with EC technology from Eddyfi Technologies where good surface detection was recorded with volumetric inspection with UT. The main technology was for stress corrosion cracking, or SCC, so eddy current was the lead technology with detection by EC volumetric done at the same time. The point here is that you can combine good technology for certain applications; there’s a synergistic approach.

It’s only fair that if we talk about the highlights that I also ask if there any drawbacks to the technology.

If we talk about challenges by the technology itself, one thing is that it does require more training for technicians. The Sharck probe is more complex than conventional eddy current and EC by definition also requires a lot of training. If you compare training with MT, there’s much more. There’s no official certification for technology like this and often the client will not only need to have confidence in the technology but also the technician doing the inspection. Nucleom developed a specific internal SNT-TC-A1 certification program to certify our technicians. Since it is an internal certificate program, it is sometimes not as accepted as what third party certifying bodies do. This is sometimes a challenge for us.

If you check the number of ultrasonic or radiographic technicians in Canada, there’s way less eddy current technicians. Even if we want to hire new technicians, there’s not a lot. Ten years ago, they said that the average technician was in his 50s. I wouldn’t say that’s still true, but there’s a large portion of technicians that aren’t that good with technology. You can be a good NDT technician, but you need to be able to manipulate a computer and that has an impact over technology like this. It’s something that needs to be addressed today, but it’s not a long-term problem.

On the topic of being comfortable with the technology, can you speak to the quality of the data output for tangential eddy current array inspections with the Sharck?

The image capabilities of the Sharck are very interesting. The software offers differentiation of signals for axial and circumferential indications. You can differentiate or characterize the different indications. A technical manager or anyone with 10 to 15 minutes of basic training could understand the signal response. If you show the signals from a calibration block, an asset owner or manager will understand what he’s looking at. In NDT in general, that’s why we calibrate, to have a basic pattern when the material is good. The readings are interpreted by a human and further characterized.

The next step is to have machine learning or artificial intelligence over what the technician can interpret. That’s coming, all manufacturers are working on it. In the short term, it will help increase confidence of the technician, and much further in time, I wouldn’t be surprised if a human could have a full interpretation made by the Sharck.

One day soon, Eddyfi Technologies is always pushing the limits of NDT forward! Going a bit broader here, what advice would you offer to those that depend on non-destructive testing to make important business decisions?

Like you said, it’s a large question. When the economy is good, there is a lot of manufacturing and fabrication. Companies are dedicated to their clients, and they want to put a good component on the market, so good quality control is important. For many manufacturing applications or new fabrication, it’s really important to have good NDT capabilities or incorporate NDT into the quality control process for good components. It will often be seen as spending, but I always tell them that it’s not an expense but rather an investment. The money they invest in good quality control with hurt them far less than down the road, so they should see NDT as an investment. When the economy is not necessarily good or you have components in the field, you likely want to try to extend their useful life and make sure that they’re safe to people so again incorporating quality control with a good NDT process can literally save lives and extend their component life.

To end things off, what is important for our readers to know about Nucleom?

We have many advantages specifically with Eddyfi Technologies offering. Nucleom likes to use high technology, we like to use good products, and we’re good at manipulating them. If you’re thinking about going for an eddy current inspection, Nucleom offers high quality service. We like to be innovative and another key point that not all other companies have is that we can combine different advantages of different technologies together: we’re not only good at eddy current but many different technologies. We’re developing parallel services like welding engineering and 3D scanning capabilities, fitness-for-service services and so on so we can offer an inspection campaign around the NDT needs of a client. We’re a young team, really proud, really proactive, and we like our jobs!

Well on behalf of our readers, thanks for sharing your expertise with us today Francis!

For those interested in learning more about Nucleom, visit their website here, and if you’re interested in leveraging Eddyfi Technologies advanced inspection technologies to stay Beyond Current, get in touch with our experts today.

Thanks for joining today, Francis. To give our readers a little background, can you tell us what drew you to non-destructive testing?

I studied physics engineering around 2000, and at the time, Sebastien Savard – an Eddyfi Technologies employee who was working at R/D Tech then – came and gave a presentation while I was a student. I was already majoring in material science, so I found what R/D Tech was doing very interesting and always thought that I could have a career in NDT. The first year out of school there was an opening, I was invited to join, and that’s how I got started.

Since then, I’ve always stayed in NDT. For the last 20 years, I’ve had the chance to travel the world (well not for a year now under the given circumstances). I have been onsite a lot, so I have a good mix of theory and hands-on experience as well. Having worked a couple of times with Olympus, I then took a position in a small service company startup in Quebec City. I left roughly 10 years ago and formed a company with my brothers; it was not so big at that time but then we merged. It has now been five years this year at Nucleom.

What do you enjoy most as Lead Engineer at Nucleom?

I just finished a management degree last year, and I do like management, but what I enjoy most is the technical side of NDT. The number of different industries you serve keeps things interesting. For example, I have a good friend who works in an aluminum plant, so he’s doing that all the time. For me, I work with aerospace, oil and gas, construction and more so you can touch a lot of good technology. I like my role because I am involved with a lot of projects at Nucleom, not just one. Not that many people know this field, and when people ask what I do, I say I’m a doctor but for industrial parts.

That’s a good way to put it! So, I understand Nucleom uses quite a few different Eddyfi Technologies solutions... everything from the Floormap to the Ectane and Reddy. Can you speak to why Nucleom chose Eddyfi Technologies for their advanced inspection solutions?

First of all, we have a deep relationship beyond the business connection. Our historical roots include Martin Theriault, the CEO of Eddyfi NDT, being my boss’s CEO early in their careers. There’s a lot of people between our two groups who have known each other at different phases of our careers. Not only is there the trust in the technology and projects that Eddyfi offers, but there is also a high confidence level. For Nucleom, there’s a comparative advantage of other similar companies, and to be honest, Eddyfi is really proactive. We like to define ourselves as a high technology company and Eddyfi Technologies offers good, high tech products, so right there, even if we did not have a deep connection, I think we would still use Eddyfi Technologies’ solutions.

That’s great feedback. I understand that the Eddyfi Sharck probe featuring TECA technology is among the NDT toolbox for Nucleom. Can you offer a good example of an application where this probe is used?

Yes, for sure. We have a broad range of applications, so I’ll focus on weld applications today. There was a cool project in the Middle East where we used the Sharck probe specifically for pressure swing adsorption vessels, or PSAs. A PSA is basically a tank and because of the function of that tank, there’s a cycle that puts strain on the welds. Over time, these welds can develop cracking while in service. For this job, there was a lot of tanks requiring weld inspection, and the Sharck was perfect for recording everything and doing all the components for the client. In particular, there were some areas where you had a circumferential and an axial weld crossing in a dead zone that was overcome with use of the Sharck.

We also use the Sharck often in the Montreal area where we have an office and do a lot of refinery and oil and gas industry inspections. We use it almost every week. We’ll still do conventional techniques like Magnetic Particle Inspection, or MPI/MT, but we complement these kinds of inspections with the Sharck. When you take something with MT, you don’t have a sizing capability, so if an indication is detected, it can be confirmed with the Sharck probe. There can be an area where the yolk isn’t good for detection, so we directly use the Sharck probe because the tip is smaller, and we can reach confined or difficult-to-access areas. By definition with MT, you need to look at how the component looks to see the powder, but because you can reach with the Sharck probe and look at your instrument screen instead, you’re offered some advantages especially when looking directly at a component in a dark area or behind something that you can’t directly see.

Good point. So, you’ve started to answer why you’d use the Sharck over more conventional techniques like MPI, and it sounds like access is obviously a factor for obtaining that recordable result.

There are a few environmental factors. In the case of the Middle East inspection, being outdoors with sand in the wind makes an MT inspection really difficult. Even at home in Quebec City where there’s wind without sand, it can be a challenge: you throw powder and then it goes to the wind – it can be done but it’s more difficult so when you think about when there’s stuff in the air, you can imagine how much more difficult this becomes.

Cold is another factor that makes MT difficult. If we were asked to do an inspection in winter conditions, Sharck would be a good choice because of the below freezing point. You don’t have to manipulate power, and it probably wouldn’t be possible with a black and white technique anyway. All this is related to the surface condition also. While you still need good surface preparation for the Sharck technology, it has an edge over MT.

Then back to you comment about access, being able to reach areas in scaffolding or in a harness with MT, I’ve seen guys doing it, but it’s very inconvenient. You need to throw your powder and have two hands near the component but with the Sharck probe, you can be really stable reach with your arm extended.

What would say then was the main driver for selecting the Sharck to inspect the many pressure swing adsorption vessel carbon steel welds?

The main factor is a faster inspection offered by Sharck. Thinking of the example in the Middle East, there were so many components or welds to inspect that it would not have been practical to have a 100 percent weld inspection by conventional methods. This equipment often needs to be inspected during a shutdown which means stopping production when stopping their usage, so for the client it’s not only a cost to inspect but they’re also losing money with the equipment stopped. So, the advantage of the Sharck was being able to do 100 percent of the inspection in the allowed time window.

Another point is the probability of detection and the probability of sizing are better than MT because MT is human based. The technician needs to stay attentive to what he’s doing the entire time. I can tell you having been in the industry for years and it’s just human law -even when you drive your car- I think the attention span is like 98-99% on average, but there’s still one or two percent that you don’t pay enough attention to the road. It’s the same thing for MT. Even good technicians cannot pay attention 100% of the time, so it reduces the probability of detection for indications. With the Sharck probe, you don’t encounter that since you’re recording everything that you can check later. You can perform a quality review because the inspection is recorded, and your detection and sizing accuracy are higher on average.

Anyway, a technician deploying the Sharck probe will be competent with MT, so we’ll have a yolk in case of standards, sometimes. There’s a human relation over technical aspect as well where you’ll have a manager think we’re performing black magic, but when you have an MT inspection, you can directly see the powder conglomerate around a crack to prove what you’re finding, so the point is that we can have MT as a backup for different reasons when we do a campaign.

You touched on how the Middle East job had many vessels and for these bigger inspection jobs, the Sharck is ideal because it’s faster than MPI. Could you compare the time spent here or against a single element probe?

The Sharck or Eddy Current Array (ECA) in general offers a bigger paintbrush, so for applications with large surface, more quantities, or length, it will definitely help to have array technology available. The welds from the Middle East application were really large. Not all welds are like that, it depends on the thickness of the component: the thicker the component, the larger the weld tends to be. When you have an array, you can do a single scan. When you consider it takes three to four scans with a single probe, an array saves four times the work. That doesn’t even count calibration and setting up the equipment and all like that.

Sharck can naturally replace magnetic particle but also penetrant testing. Penetrant testing is dirty and requires a lot of consumables. From the service company’s point of view, the added value of services over MT or dye penetrant testing given how fast Sharck is and all benefits discussed, there is a really good business case. The asset owner benefits too. You can squeeze inspections in shorter windows, there’s less production stoppage, and cost savings all around.

We partnered with Eddyfi Technologies on another big project where the asset owner built a pipe section simulating real conditions, and just to give you an idea, they invested half a million dollars to build four different pipe configuration components. There were a lot of different artificial defects, and we were able to use it for external cracking or external detection. We did a full body inspection with the Sharck HR probe. That’s where we have comparative numbers. It was faster using the Sharck HR rather than doing a full MT. The same would apply for weld inspection. For example, on these pipes, there were ERW welds, and we did a specific scan with the Sharck for them that was harder and slower with MT. On top of having the recorded data, we benefited from the higher probability of detection again.

When talking about technologies in combination over replacement, and maybe less related to welds, we’ve done a few large scope projects. There was one nuclear application where we combined UT with EC technology from Eddyfi Technologies where good surface detection was recorded with volumetric inspection with UT. The main technology was for stress corrosion cracking, or SCC, so eddy current was the lead technology with detection by EC volumetric done at the same time. The point here is that you can combine good technology for certain applications; there’s a synergistic approach.

It’s only fair that if we talk about the highlights that I also ask if there any drawbacks to the technology.

If we talk about challenges by the technology itself, one thing is that it does require more training for technicians. The Sharck probe is more complex than conventional eddy current and EC by definition also requires a lot of training. If you compare training with MT, there’s much more. There’s no official certification for technology like this and often the client will not only need to have confidence in the technology but also the technician doing the inspection. Nucleom developed a specific internal SNT-TC-A1 certification program to certify our technicians. Since it is an internal certificate program, it is sometimes not as accepted as what third party certifying bodies do. This is sometimes a challenge for us.

If you check the number of ultrasonic or radiographic technicians in Canada, there’s way less eddy current technicians. Even if we want to hire new technicians, there’s not a lot. Ten years ago, they said that the average technician was in his 50s. I wouldn’t say that’s still true, but there’s a large portion of technicians that aren’t that good with technology. You can be a good NDT technician, but you need to be able to manipulate a computer and that has an impact over technology like this. It’s something that needs to be addressed today, but it’s not a long-term problem.

On the topic of being comfortable with the technology, can you speak to the quality of the data output for tangential eddy current array inspections with the Sharck?

The image capabilities of the Sharck are very interesting. The software offers differentiation of signals for axial and circumferential indications. You can differentiate or characterize the different indications. A technical manager or anyone with 10 to 15 minutes of basic training could understand the signal response. If you show the signals from a calibration block, an asset owner or manager will understand what he’s looking at. In NDT in general, that’s why we calibrate, to have a basic pattern when the material is good. The readings are interpreted by a human and further characterized.

The next step is to have machine learning or artificial intelligence over what the technician can interpret. That’s coming, all manufacturers are working on it. In the short term, it will help increase confidence of the technician, and much further in time, I wouldn’t be surprised if a human could have a full interpretation made by the Sharck.

One day soon, Eddyfi Technologies is always pushing the limits of NDT forward! Going a bit broader here, what advice would you offer to those that depend on non-destructive testing to make important business decisions?

Like you said, it’s a large question. When the economy is good, there is a lot of manufacturing and fabrication. Companies are dedicated to their clients, and they want to put a good component on the market, so good quality control is important. For many manufacturing applications or new fabrication, it’s really important to have good NDT capabilities or incorporate NDT into the quality control process for good components. It will often be seen as spending, but I always tell them that it’s not an expense but rather an investment. The money they invest in good quality control with hurt them far less than down the road, so they should see NDT as an investment. When the economy is not necessarily good or you have components in the field, you likely want to try to extend their useful life and make sure that they’re safe to people so again incorporating quality control with a good NDT process can literally save lives and extend their component life.

To end things off, what is important for our readers to know about Nucleom?

We have many advantages specifically with Eddyfi Technologies offering. Nucleom likes to use high technology, we like to use good products, and we’re good at manipulating them. If you’re thinking about going for an eddy current inspection, Nucleom offers high quality service. We like to be innovative and another key point that not all other companies have is that we can combine different advantages of different technologies together: we’re not only good at eddy current but many different technologies. We’re developing parallel services like welding engineering and 3D scanning capabilities, fitness-for-service services and so on so we can offer an inspection campaign around the NDT needs of a client. We’re a young team, really proud, really proactive, and we like our jobs!

Well on behalf of our readers, thanks for sharing your expertise with us today Francis!

For those interested in learning more about Nucleom, visit their website here, and if you’re interested in leveraging Eddyfi Technologies advanced inspection technologies to stay Beyond Current, get in touch with our experts today.

Thanks for joining today, Francis. To give our readers a little background, can you tell us what drew you to non-destructive testing?

I studied physics engineering around 2000, and at the time, Sebastien Savard – an Eddyfi Technologies employee who was working at R/D Tech then – came and gave a presentation while I was a student. I was already majoring in material science, so I found what R/D Tech was doing very interesting and always thought that I could have a career in NDT. The first year out of school there was an opening, I was invited to join, and that’s how I got started.

Since then, I’ve always stayed in NDT. For the last 20 years, I’ve had the chance to travel the world (well not for a year now under the given circumstances). I have been onsite a lot, so I have a good mix of theory and hands-on experience as well. Having worked a couple of times with Olympus, I then took a position in a small service company startup in Quebec City. I left roughly 10 years ago and formed a company with my brothers; it was not so big at that time but then we merged. It has now been five years this year at Nucleom.

What do you enjoy most as Lead Engineer at Nucleom?

I just finished a management degree last year, and I do like management, but what I enjoy most is the technical side of NDT. The number of different industries you serve keeps things interesting. For example, I have a good friend who works in an aluminum plant, so he’s doing that all the time. For me, I work with aerospace, oil and gas, construction and more so you can touch a lot of good technology. I like my role because I am involved with a lot of projects at Nucleom, not just one. Not that many people know this field, and when people ask what I do, I say I’m a doctor but for industrial parts.

That’s a good way to put it! So, I understand Nucleom uses quite a few different Eddyfi Technologies solutions... everything from the Floormap to the Ectane and Reddy. Can you speak to why Nucleom chose Eddyfi Technologies for their advanced inspection solutions?

First of all, we have a deep relationship beyond the business connection. Our historical roots include Martin Theriault, the CEO of Eddyfi NDT, being my boss’s CEO early in their careers. There’s a lot of people between our two groups who have known each other at different phases of our careers. Not only is there the trust in the technology and projects that Eddyfi offers, but there is also a high confidence level. For Nucleom, there’s a comparative advantage of other similar companies, and to be honest, Eddyfi is really proactive. We like to define ourselves as a high technology company and Eddyfi Technologies offers good, high tech products, so right there, even if we did not have a deep connection, I think we would still use Eddyfi Technologies’ solutions.

That’s great feedback. I understand that the Eddyfi Sharck probe featuring TECA technology is among the NDT toolbox for Nucleom. Can you offer a good example of an application where this probe is used?

Yes, for sure. We have a broad range of applications, so I’ll focus on weld applications today. There was a cool project in the Middle East where we used the Sharck probe specifically for pressure swing adsorption vessels, or PSAs. A PSA is basically a tank and because of the function of that tank, there’s a cycle that puts strain on the welds. Over time, these welds can develop cracking while in service. For this job, there was a lot of tanks requiring weld inspection, and the Sharck was perfect for recording everything and doing all the components for the client. In particular, there were some areas where you had a circumferential and an axial weld crossing in a dead zone that was overcome with use of the Sharck.

We also use the Sharck often in the Montreal area where we have an office and do a lot of refinery and oil and gas industry inspections. We use it almost every week. We’ll still do conventional techniques like Magnetic Particle Inspection, or MPI/MT, but we complement these kinds of inspections with the Sharck. When you take something with MT, you don’t have a sizing capability, so if an indication is detected, it can be confirmed with the Sharck probe. There can be an area where the yolk isn’t good for detection, so we directly use the Sharck probe because the tip is smaller, and we can reach confined or difficult-to-access areas. By definition with MT, you need to look at how the component looks to see the powder, but because you can reach with the Sharck probe and look at your instrument screen instead, you’re offered some advantages especially when looking directly at a component in a dark area or behind something that you can’t directly see.

Good point. So, you’ve started to answer why you’d use the Sharck over more conventional techniques like MPI, and it sounds like access is obviously a factor for obtaining that recordable result.

There are a few environmental factors. In the case of the Middle East inspection, being outdoors with sand in the wind makes an MT inspection really difficult. Even at home in Quebec City where there’s wind without sand, it can be a challenge: you throw powder and then it goes to the wind – it can be done but it’s more difficult so when you think about when there’s stuff in the air, you can imagine how much more difficult this becomes.

Cold is another factor that makes MT difficult. If we were asked to do an inspection in winter conditions, Sharck would be a good choice because of the below freezing point. You don’t have to manipulate power, and it probably wouldn’t be possible with a black and white technique anyway. All this is related to the surface condition also. While you still need good surface preparation for the Sharck technology, it has an edge over MT.

Then back to you comment about access, being able to reach areas in scaffolding or in a harness with MT, I’ve seen guys doing it, but it’s very inconvenient. You need to throw your powder and have two hands near the component but with the Sharck probe, you can be really stable reach with your arm extended.

What would say then was the main driver for selecting the Sharck to inspect the many pressure swing adsorption vessel carbon steel welds?

The main factor is a faster inspection offered by Sharck. Thinking of the example in the Middle East, there were so many components or welds to inspect that it would not have been practical to have a 100 percent weld inspection by conventional methods. This equipment often needs to be inspected during a shutdown which means stopping production when stopping their usage, so for the client it’s not only a cost to inspect but they’re also losing money with the equipment stopped. So, the advantage of the Sharck was being able to do 100 percent of the inspection in the allowed time window.

Another point is the probability of detection and the probability of sizing are better than MT because MT is human based. The technician needs to stay attentive to what he’s doing the entire time. I can tell you having been in the industry for years and it’s just human law -even when you drive your car- I think the attention span is like 98-99% on average, but there’s still one or two percent that you don’t pay enough attention to the road. It’s the same thing for MT. Even good technicians cannot pay attention 100% of the time, so it reduces the probability of detection for indications. With the Sharck probe, you don’t encounter that since you’re recording everything that you can check later. You can perform a quality review because the inspection is recorded, and your detection and sizing accuracy are higher on average.

Anyway, a technician deploying the Sharck probe will be competent with MT, so we’ll have a yolk in case of standards, sometimes. There’s a human relation over technical aspect as well where you’ll have a manager think we’re performing black magic, but when you have an MT inspection, you can directly see the powder conglomerate around a crack to prove what you’re finding, so the point is that we can have MT as a backup for different reasons when we do a campaign.

You touched on how the Middle East job had many vessels and for these bigger inspection jobs, the Sharck is ideal because it’s faster than MPI. Could you compare the time spent here or against a single element probe?

The Sharck or Eddy Current Array (ECA) in general offers a bigger paintbrush, so for applications with large surface, more quantities, or length, it will definitely help to have array technology available. The welds from the Middle East application were really large. Not all welds are like that, it depends on the thickness of the component: the thicker the component, the larger the weld tends to be. When you have an array, you can do a single scan. When you consider it takes three to four scans with a single probe, an array saves four times the work. That doesn’t even count calibration and setting up the equipment and all like that.

Sharck can naturally replace magnetic particle but also penetrant testing. Penetrant testing is dirty and requires a lot of consumables. From the service company’s point of view, the added value of services over MT or dye penetrant testing given how fast Sharck is and all benefits discussed, there is a really good business case. The asset owner benefits too. You can squeeze inspections in shorter windows, there’s less production stoppage, and cost savings all around.

We partnered with Eddyfi Technologies on another big project where the asset owner built a pipe section simulating real conditions, and just to give you an idea, they invested half a million dollars to build four different pipe configuration components. There were a lot of different artificial defects, and we were able to use it for external cracking or external detection. We did a full body inspection with the Sharck HR probe. That’s where we have comparative numbers. It was faster using the Sharck HR rather than doing a full MT. The same would apply for weld inspection. For example, on these pipes, there were ERW welds, and we did a specific scan with the Sharck for them that was harder and slower with MT. On top of having the recorded data, we benefited from the higher probability of detection again.

When talking about technologies in combination over replacement, and maybe less related to welds, we’ve done a few large scope projects. There was one nuclear application where we combined UT with EC technology from Eddyfi Technologies where good surface detection was recorded with volumetric inspection with UT. The main technology was for stress corrosion cracking, or SCC, so eddy current was the lead technology with detection by EC volumetric done at the same time. The point here is that you can combine good technology for certain applications; there’s a synergistic approach.

It’s only fair that if we talk about the highlights that I also ask if there any drawbacks to the technology.

If we talk about challenges by the technology itself, one thing is that it does require more training for technicians. The Sharck probe is more complex than conventional eddy current and EC by definition also requires a lot of training. If you compare training with MT, there’s much more. There’s no official certification for technology like this and often the client will not only need to have confidence in the technology but also the technician doing the inspection. Nucleom developed a specific internal SNT-TC-A1 certification program to certify our technicians. Since it is an internal certificate program, it is sometimes not as accepted as what third party certifying bodies do. This is sometimes a challenge for us.

If you check the number of ultrasonic or radiographic technicians in Canada, there’s way less eddy current technicians. Even if we want to hire new technicians, there’s not a lot. Ten years ago, they said that the average technician was in his 50s. I wouldn’t say that’s still true, but there’s a large portion of technicians that aren’t that good with technology. You can be a good NDT technician, but you need to be able to manipulate a computer and that has an impact over technology like this. It’s something that needs to be addressed today, but it’s not a long-term problem.

On the topic of being comfortable with the technology, can you speak to the quality of the data output for tangential eddy current array inspections with the Sharck?

The image capabilities of the Sharck are very interesting. The software offers differentiation of signals for axial and circumferential indications. You can differentiate or characterize the different indications. A technical manager or anyone with 10 to 15 minutes of basic training could understand the signal response. If you show the signals from a calibration block, an asset owner or manager will understand what he’s looking at. In NDT in general, that’s why we calibrate, to have a basic pattern when the material is good. The readings are interpreted by a human and further characterized.

The next step is to have machine learning or artificial intelligence over what the technician can interpret. That’s coming, all manufacturers are working on it. In the short term, it will help increase confidence of the technician, and much further in time, I wouldn’t be surprised if a human could have a full interpretation made by the Sharck.

One day soon, Eddyfi Technologies is always pushing the limits of NDT forward! Going a bit broader here, what advice would you offer to those that depend on non-destructive testing to make important business decisions?

Like you said, it’s a large question. When the economy is good, there is a lot of manufacturing and fabrication. Companies are dedicated to their clients, and they want to put a good component on the market, so good quality control is important. For many manufacturing applications or new fabrication, it’s really important to have good NDT capabilities or incorporate NDT into the quality control process for good components. It will often be seen as spending, but I always tell them that it’s not an expense but rather an investment. The money they invest in good quality control with hurt them far less than down the road, so they should see NDT as an investment. When the economy is not necessarily good or you have components in the field, you likely want to try to extend their useful life and make sure that they’re safe to people so again incorporating quality control with a good NDT process can literally save lives and extend their component life.

To end things off, what is important for our readers to know about Nucleom?

We have many advantages specifically with Eddyfi Technologies offering. Nucleom likes to use high technology, we like to use good products, and we’re good at manipulating them. If you’re thinking about going for an eddy current inspection, Nucleom offers high quality service. We like to be innovative and another key point that not all other companies have is that we can combine different advantages of different technologies together: we’re not only good at eddy current but many different technologies. We’re developing parallel services like welding engineering and 3D scanning capabilities, fitness-for-service services and so on so we can offer an inspection campaign around the NDT needs of a client. We’re a young team, really proud, really proactive, and we like our jobs!

Well on behalf of our readers, thanks for sharing your expertise with us today Francis!

For those interested in learning more about Nucleom, visit their website here, and if you’re interested in leveraging Eddyfi Technologies advanced inspection technologies to stay Beyond Current, get in touch with our experts today.

Thanks for joining today, Francis. To give our readers a little background, can you tell us what drew you to non-destructive testing?

I studied physics engineering around 2000, and at the time, Sebastien Savard – an Eddyfi Technologies employee who was working at R/D Tech then – came and gave a presentation while I was a student. I was already majoring in material science, so I found what R/D Tech was doing very interesting and always thought that I could have a career in NDT. The first year out of school there was an opening, I was invited to join, and that’s how I got started.

Since then, I’ve always stayed in NDT. For the last 20 years, I’ve had the chance to travel the world (well not for a year now under the given circumstances). I have been onsite a lot, so I have a good mix of theory and hands-on experience as well. Having worked a couple of times with Olympus, I then took a position in a small service company startup in Quebec City. I left roughly 10 years ago and formed a company with my brothers; it was not so big at that time but then we merged. It has now been five years this year at Nucleom.

What do you enjoy most as Lead Engineer at Nucleom?

I just finished a management degree last year, and I do like management, but what I enjoy most is the technical side of NDT. The number of different industries you serve keeps things interesting. For example, I have a good friend who works in an aluminum plant, so he’s doing that all the time. For me, I work with aerospace, oil and gas, construction and more so you can touch a lot of good technology. I like my role because I am involved with a lot of projects at Nucleom, not just one. Not that many people know this field, and when people ask what I do, I say I’m a doctor but for industrial parts.

That’s a good way to put it! So, I understand Nucleom uses quite a few different Eddyfi Technologies solutions... everything from the Floormap to the Ectane and Reddy. Can you speak to why Nucleom chose Eddyfi Technologies for their advanced inspection solutions?

First of all, we have a deep relationship beyond the business connection. Our historical roots include Martin Theriault, the CEO of Eddyfi NDT, being my boss’s CEO early in their careers. There’s a lot of people between our two groups who have known each other at different phases of our careers. Not only is there the trust in the technology and projects that Eddyfi offers, but there is also a high confidence level. For Nucleom, there’s a comparative advantage of other similar companies, and to be honest, Eddyfi is really proactive. We like to define ourselves as a high technology company and Eddyfi Technologies offers good, high tech products, so right there, even if we did not have a deep connection, I think we would still use Eddyfi Technologies’ solutions.

That’s great feedback. I understand that the Eddyfi Sharck probe featuring TECA technology is among the NDT toolbox for Nucleom. Can you offer a good example of an application where this probe is used?

Yes, for sure. We have a broad range of applications, so I’ll focus on weld applications today. There was a cool project in the Middle East where we used the Sharck probe specifically for pressure swing adsorption vessels, or PSAs. A PSA is basically a tank and because of the function of that tank, there’s a cycle that puts strain on the welds. Over time, these welds can develop cracking while in service. For this job, there was a lot of tanks requiring weld inspection, and the Sharck was perfect for recording everything and doing all the components for the client. In particular, there were some areas where you had a circumferential and an axial weld crossing in a dead zone that was overcome with use of the Sharck.

We also use the Sharck often in the Montreal area where we have an office and do a lot of refinery and oil and gas industry inspections. We use it almost every week. We’ll still do conventional techniques like Magnetic Particle Inspection, or MPI/MT, but we complement these kinds of inspections with the Sharck. When you take something with MT, you don’t have a sizing capability, so if an indication is detected, it can be confirmed with the Sharck probe. There can be an area where the yolk isn’t good for detection, so we directly use the Sharck probe because the tip is smaller, and we can reach confined or difficult-to-access areas. By definition with MT, you need to look at how the component looks to see the powder, but because you can reach with the Sharck probe and look at your instrument screen instead, you’re offered some advantages especially when looking directly at a component in a dark area or behind something that you can’t directly see.

Good point. So, you’ve started to answer why you’d use the Sharck over more conventional techniques like MPI, and it sounds like access is obviously a factor for obtaining that recordable result.

There are a few environmental factors. In the case of the Middle East inspection, being outdoors with sand in the wind makes an MT inspection really difficult. Even at home in Quebec City where there’s wind without sand, it can be a challenge: you throw powder and then it goes to the wind – it can be done but it’s more difficult so when you think about when there’s stuff in the air, you can imagine how much more difficult this becomes.

Cold is another factor that makes MT difficult. If we were asked to do an inspection in winter conditions, Sharck would be a good choice because of the below freezing point. You don’t have to manipulate power, and it probably wouldn’t be possible with a black and white technique anyway. All this is related to the surface condition also. While you still need good surface preparation for the Sharck technology, it has an edge over MT.

Then back to you comment about access, being able to reach areas in scaffolding or in a harness with MT, I’ve seen guys doing it, but it’s very inconvenient. You need to throw your powder and have two hands near the component but with the Sharck probe, you can be really stable reach with your arm extended.

What would say then was the main driver for selecting the Sharck to inspect the many pressure swing adsorption vessel carbon steel welds?

The main factor is a faster inspection offered by Sharck. Thinking of the example in the Middle East, there were so many components or welds to inspect that it would not have been practical to have a 100 percent weld inspection by conventional methods. This equipment often needs to be inspected during a shutdown which means stopping production when stopping their usage, so for the client it’s not only a cost to inspect but they’re also losing money with the equipment stopped. So, the advantage of the Sharck was being able to do 100 percent of the inspection in the allowed time window.

Another point is the probability of detection and the probability of sizing are better than MT because MT is human based. The technician needs to stay attentive to what he’s doing the entire time. I can tell you having been in the industry for years and it’s just human law -even when you drive your car- I think the attention span is like 98-99% on average, but there’s still one or two percent that you don’t pay enough attention to the road. It’s the same thing for MT. Even good technicians cannot pay attention 100% of the time, so it reduces the probability of detection for indications. With the Sharck probe, you don’t encounter that since you’re recording everything that you can check later. You can perform a quality review because the inspection is recorded, and your detection and sizing accuracy are higher on average.

Anyway, a technician deploying the Sharck probe will be competent with MT, so we’ll have a yolk in case of standards, sometimes. There’s a human relation over technical aspect as well where you’ll have a manager think we’re performing black magic, but when you have an MT inspection, you can directly see the powder conglomerate around a crack to prove what you’re finding, so the point is that we can have MT as a backup for different reasons when we do a campaign.

You touched on how the Middle East job had many vessels and for these bigger inspection jobs, the Sharck is ideal because it’s faster than MPI. Could you compare the time spent here or against a single element probe?

The Sharck or Eddy Current Array (ECA) in general offers a bigger paintbrush, so for applications with large surface, more quantities, or length, it will definitely help to have array technology available. The welds from the Middle East application were really large. Not all welds are like that, it depends on the thickness of the component: the thicker the component, the larger the weld tends to be. When you have an array, you can do a single scan. When you consider it takes three to four scans with a single probe, an array saves four times the work. That doesn’t even count calibration and setting up the equipment and all like that.

Sharck can naturally replace magnetic particle but also penetrant testing. Penetrant testing is dirty and requires a lot of consumables. From the service company’s point of view, the added value of services over MT or dye penetrant testing given how fast Sharck is and all benefits discussed, there is a really good business case. The asset owner benefits too. You can squeeze inspections in shorter windows, there’s less production stoppage, and cost savings all around.

We partnered with Eddyfi Technologies on another big project where the asset owner built a pipe section simulating real conditions, and just to give you an idea, they invested half a million dollars to build four different pipe configuration components. There were a lot of different artificial defects, and we were able to use it for external cracking or external detection. We did a full body inspection with the Sharck HR probe. That’s where we have comparative numbers. It was faster using the Sharck HR rather than doing a full MT. The same would apply for weld inspection. For example, on these pipes, there were ERW welds, and we did a specific scan with the Sharck for them that was harder and slower with MT. On top of having the recorded data, we benefited from the higher probability of detection again.

When talking about technologies in combination over replacement, and maybe less related to welds, we’ve done a few large scope projects. There was one nuclear application where we combined UT with EC technology from Eddyfi Technologies where good surface detection was recorded with volumetric inspection with UT. The main technology was for stress corrosion cracking, or SCC, so eddy current was the lead technology with detection by EC volumetric done at the same time. The point here is that you can combine good technology for certain applications; there’s a synergistic approach.

It’s only fair that if we talk about the highlights that I also ask if there any drawbacks to the technology.

If we talk about challenges by the technology itself, one thing is that it does require more training for technicians. The Sharck probe is more complex than conventional eddy current and EC by definition also requires a lot of training. If you compare training with MT, there’s much more. There’s no official certification for technology like this and often the client will not only need to have confidence in the technology but also the technician doing the inspection. Nucleom developed a specific internal SNT-TC-A1 certification program to certify our technicians. Since it is an internal certificate program, it is sometimes not as accepted as what third party certifying bodies do. This is sometimes a challenge for us.

If you check the number of ultrasonic or radiographic technicians in Canada, there’s way less eddy current technicians. Even if we want to hire new technicians, there’s not a lot. Ten years ago, they said that the average technician was in his 50s. I wouldn’t say that’s still true, but there’s a large portion of technicians that aren’t that good with technology. You can be a good NDT technician, but you need to be able to manipulate a computer and that has an impact over technology like this. It’s something that needs to be addressed today, but it’s not a long-term problem.

On the topic of being comfortable with the technology, can you speak to the quality of the data output for tangential eddy current array inspections with the Sharck?

The image capabilities of the Sharck are very interesting. The software offers differentiation of signals for axial and circumferential indications. You can differentiate or characterize the different indications. A technical manager or anyone with 10 to 15 minutes of basic training could understand the signal response. If you show the signals from a calibration block, an asset owner or manager will understand what he’s looking at. In NDT in general, that’s why we calibrate, to have a basic pattern when the material is good. The readings are interpreted by a human and further characterized.

The next step is to have machine learning or artificial intelligence over what the technician can interpret. That’s coming, all manufacturers are working on it. In the short term, it will help increase confidence of the technician, and much further in time, I wouldn’t be surprised if a human could have a full interpretation made by the Sharck.

One day soon, Eddyfi Technologies is always pushing the limits of NDT forward! Going a bit broader here, what advice would you offer to those that depend on non-destructive testing to make important business decisions?

Like you said, it’s a large question. When the economy is good, there is a lot of manufacturing and fabrication. Companies are dedicated to their clients, and they want to put a good component on the market, so good quality control is important. For many manufacturing applications or new fabrication, it’s really important to have good NDT capabilities or incorporate NDT into the quality control process for good components. It will often be seen as spending, but I always tell them that it’s not an expense but rather an investment. The money they invest in good quality control with hurt them far less than down the road, so they should see NDT as an investment. When the economy is not necessarily good or you have components in the field, you likely want to try to extend their useful life and make sure that they’re safe to people so again incorporating quality control with a good NDT process can literally save lives and extend their component life.

To end things off, what is important for our readers to know about Nucleom?

We have many advantages specifically with Eddyfi Technologies offering. Nucleom likes to use high technology, we like to use good products, and we’re good at manipulating them. If you’re thinking about going for an eddy current inspection, Nucleom offers high quality service. We like to be innovative and another key point that not all other companies have is that we can combine different advantages of different technologies together: we’re not only good at eddy current but many different technologies. We’re developing parallel services like welding engineering and 3D scanning capabilities, fitness-for-service services and so on so we can offer an inspection campaign around the NDT needs of a client. We’re a young team, really proud, really proactive, and we like our jobs!

Well on behalf of our readers, thanks for sharing your expertise with us today Francis!

For those interested in learning more about Nucleom, visit their website here, and if you’re interested in leveraging Eddyfi Technologies advanced inspection technologies to stay Beyond Current, get in touch with our experts today.

Francis Boudreault-Leclerc is the Lead Engineer at Nucleom, a Canadian non-destructive testing (NDT) company known for developing and executing the most effective NDT methods, techniques, and strategies to address the needs of clients across a broad range of industries. Given his strong history in NDT, Francis understands the risks of not using the best available instruments on the market to collect the most reliable data ultimately used by asset owners to make critical business decisions related to vessels, for example. He weighs in here on why tangential eddy current array was chosen for the inspection of Pressure Swing Adsorption (PSA) vessel carbon steel welds.

.png)