As a long term Teletest user, I was excited to get the opportunity to spend two weeks onsite putting Eddyfi Technologies’ new Sonyks system through its paces. During this process, we tested the Sonyks alongside the Teletest Focus + system. These were our findings.

As part of the two-week site visit, the intention was to use both the Focus+ and Sonyks systems side-by-side to help highlight the noteworthy differences between both systems. Several 8-inch and 4-inch diameter pipes had been preselected for the purposes of this trial.

The first day on site was an exciting experience. Obviously, the team was keen to start using the Sonyks system straight away. The first few shots that we took felt unusual as we were at a novice level with both the hardware and software. We were so used to the Focus+ system and the Wavescan software that it took a little time to get acclimated; we had been doing things a certain way for ten years, and now everything was changing. We had to adapt to this new technology and a new way of working. Even after ten years, it's incredible how quickly you adapt; this is no accident. This is a testament to the excellent product design in both the Sonyks hardware and software.

Both of the teams onsite had been using the previous system for ten years; we were involved in developing that product, so we had a lot of emotional attachment to it. We knew that system like the back of our hands and had spent thousands of hours using it in various applications all over the globe. However, within one working shift, we were converted!

What was it about this new long-range ultrasonic testing system that had us not wanting to go back to using a product we were current experts with? Let's take a look…

Hardware

When we think of a piece of NDT equipment, specifically hardware, what feelings do we want that piece of equipment to evoke? I can think of several keywords. Reliable, simple, portable, and a feeling that it was designed by people that understand what it's like to work under the harsh conditions that NDT technicians are commonly subjected to. These are just some of the feelings I can recall from this experience. Sonyks hardware has a robust feel; I felt confident that it can take on all the onsite working conditions faced. The system is simple to construct with only four component parts. This makes the setup lightning-fast and the system extremely portable. An 8-inch complete system is now an easy one-man carry.

The collar itself is flexible and, as such, is easier to pack, carry, and install onto the pipe. An industry first, the collar has a true single connector at the unit and collar end. The collar has a military feel to it. It comes equipped with several lifting lugs that are distributed along its length. Although I didn't need to use this feature, it will benefit specific applications such as elevated and offshore pipe inspections.

One of the hardware benefits that I really enjoyed was not having to use a laptop. The system is compatible with a laptop PC; however, data acquisition and analysis can be performed straight from the unit. Software features can be controlled from the units' hard buttons and by the touchscreen. For me, this touchscreen is a gamechanger. The touchscreen opens up a multitude of fantastic software features, some of which I will discuss later. One of the most noteworthy things is how quick the system goes from car to pipe testing. After pulling up to a pipe location, the system is performing testing within a matter of minutes. Just connect the collar to the pipe, connect the tool lead and air hose, and away you go. The process is also expedited as there is no requirement for a manual capacitance test; this functional check is now taken care of automatically with no need for additional equipment, helping lighten the load.

The Sonyks system is lightweight and comfortable to use. It can be positioned on pipework securely with the help of the retractable rear stand. Historically, I have been a fan of using a ruggedized laptop. Still, I must admit, not having to use one is very refreshing. Laptops can be challenging to use in some scenarios. The mouse pad requires the use of both hands and positioning the laptop at a comfortable working height can be problematic. These types of issues are not experienced with the Sonyks system due to its thoughtful design.

A final noteworthy component of the new Sonyks system is the improved transducer ring spacing of 17 millimeters (0.7 inches). This optimized spacing delivers a broader range of frequencies, devoid of unusable frequencies.

Software

Software

The software has far too many great features to mention in one blog, so I will stick with those that stuck out to me.

First, the software was fun to use; I found myself smiling as I used the new features. As a former guided wave inspector, many of the features I had hoped for were addressed. When using the software, you quickly see how the interpretation process has been made almost effortless. The onboard software tools create a simplicity that will be welcomed by both new and experienced users. The seamless flow from setup mode to acquisition is incredible. Although different and vastly improved, users of Teletest and other Eddyfi Technologies products will be familiar with its format.

Now, users only need to annotate features on one frequency. These annotations are then displayed across the entire frequency range. The Distance Amplitude Correction (DAC) curves are also ganged across the whole frequency range, so users only need to set these once using a choice of several new and innovative methods. Both of these features are incredibly helpful and create considerable time savings. As a result of the above, users now use more frequencies in the analysis process; therefore, these features will likely contribute to an improved Probability of Detection (PoD). Navigating between frequencies using the frequency slider is such a powerful tool. It allows the user to study feature responses in a much more fluid and effective way.

The pan and zoom features are fantastic to use. The user can scroll around the A- or C-scans with the touch of a finger. Zooming in and out is activated by pinching the screen, identical to the same motion on a smart phone or tablet. What's really cool about this feature is that you can instantly snap back to original scale with the click of a button.

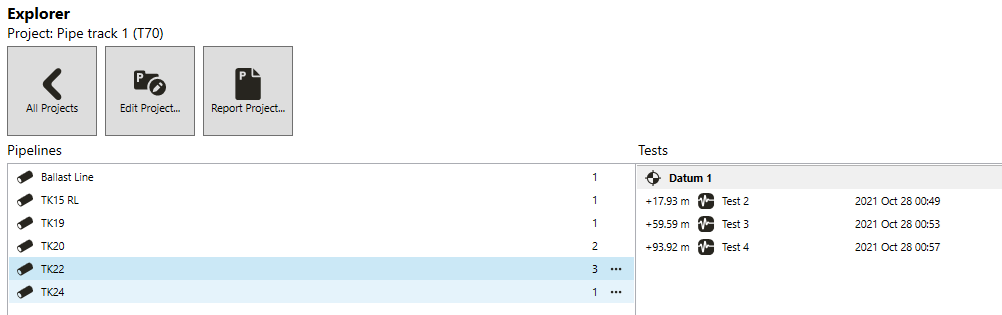

The software uses a project-based system. All pipes tested under a specific location can be viewed; the software displays each test for each pipeline and divides that into datums. This feature is excellent for several reasons but particularly helps in constructing the new and hugely improved reports. Dividing the pipes by datum allows the software to identify whether the entire line has been inspected. The final report can display coverage via a pipe coverage map, making it very easy for the technician and end user to understand precisely what has and hasn't been inspected. This feature alone offers the technician substantial time savings.

One of my favorite Sonyks features is that it now acquires data using Full Matrix Capture (FMC). FMC has been used in the medical and NDT industry for some time. Eddyfi Technologies has now applied this acquisition method to guided waves, and the benefits are tremendous. FMC ensures that all the data ever needed is captured. This essentially means that focusing can be conducted away from the pipe. There is no need to spend time at the pipe location scrutinizing the A-scan in uncomfortable or inclement conditions. Real focus data can be obtained from the comfort of an office days after the inspection took place. The obvious benefit here is a substantial productivity increase. However, for me, some of the benefits are a little more subtle.

Guided wave and NDT technicians out there will understand the pressures that are faced on site. We are expected to balance productivity and a comprehensive inspection. On some occasions, we visit remote locations with tiny windows of opportunity to achieve our goals so we have to get things right the first time, every time. The result of visiting a remote location and not collecting sufficient information can affect inspection quality. I remember an inspection I did several years ago in the Algerian Sahara. Our team of expert drivers got us to remote pipe locations traversing sand dunes and regions devoid of roads. In addition, due to the region's hostile nature, we were provided with an armed escort for our protection. These additional resources had to be arranged ahead of time with a raft of supporting work permits and risk assessments. Considering all of these factors, returning to a location would have been out of the question. This responsibility to ensure that sufficient data was collected created a high level of stress. All of the data had to be reviewed at the location to establish if additional acquisitions were required. The Sonyks system with its FMC makes these stresses a thing of the past. Sonyks will look after level 1 technicians and be the best friend of level 2s. Inspection managers will be confident that anyone in their inspection team will come back with the same data as these decisions are no longer experienced based. All data ever needed is collected as standard. FMC is a gamechanger for guided wave inspections.

In this blog, I have only mentioned a small portion of what the Sonyks guided wave testing system is capable of. I realize that some readers may think that I am biased; I work for Eddyfi Technologies so of course I will give a positive review for our new guided wave product. In all honesty, it's true; I am biased. However, I have been involved with guided waves for a long time; I have used many systems in multiple locations around the globe. I've trained hundreds of guided wave techs, so I feel that I have an excellent idea of what people want in a guided wave tool, and Sonyks is it.

Don't, however, take my word for it. Take a look yourself, book a demo, and see the real step change firsthand. Like me, once you have used Sonyks, you will not want to go back to your current guided wave system. Take control. Be your own guide. Contact our team to learn about Sonyks today.