Let’s get into the thick of it

The challenges faced during inspections of thick plate surfaces arise from a combination of real-world conditions and NDT equipment limitations. Even seasoned inspectors approach a 16-millimeter (0.6-inch) with care due to the frequent compromise of inspection requirements (not quite ready to call yourself seasoned? Check out the Eddyfi Academy). In certain circumstances, higher reporting thresholds are set, leading to shorter inspection durations. Furthermore, a significant amount of time is dedicated to validating indications, resulting in reduced inspection efficiency. Occasionally, thick plate surfaces are deemed too difficult to inspect entirely. As a result, developing dependable maintenance and repair strategies that enhance asset life cycles has been a persistent challenge in the past.

Enter the FloormapX tank floor scanner eliminating the need for compromise and surpassing the limitations of traditional MFL equipment. With its state-of-the-art technology, this scanner empowers inspectors to develop robust maintenance and repair strategies, effectively prolonging the lifespan of aboveground storage tanks in active use. The FloormapX leverages the inherent benefits of magnetic flux leakage technology, making it highly attractive for inspecting large ferrous surface areas.

- High Probability of Detection: Detects defects as small as 1mm (0.04in) in diameter.

- Critical Zone Inspection: Operates efficiently within 12mm (0.5in) of the shell wall for comprehensive assessment.

- Total Inspection Efficiency: Operates at speeds of up to 1m (3ft) per second and incorporates customer-driven features for optimal tank floor inspection.

But here’s the skinny

As with any technology, limitations exist. It is widely acknowledged that the majority of aboveground storage tank floors consist of plates typically coated with a maximum thickness of 12 millimeters (0.5 inches). Although less common, there are instances where tanks with floor plate thicknesses of 16 millimeters (0.6 inches) need to be inspected, posing a significant challenge for MFL tank floor scanners. This emphasizes the importance of tank floor inspection equipment that can deliver exceptional performance for all plate thicknesses up to and including 16mm.

However, this is not the full story. There are situations where storage tanks floors and other structures, which are otherwise well-suited for MFL, require the inspection of even thicker steel plates measuring 18 or 20 millimeters (0.7 or 0.8 inches) So, what is the solution in these scenarios?

With more advanced and powerful equipment, the benefits of MFL-based tank floor inspection can now be extended to these thick plates. FloormapX enables efficient and confident inspection of tank floors and infrastructure up to 20mm thick.

Results that aren’t just surface deep

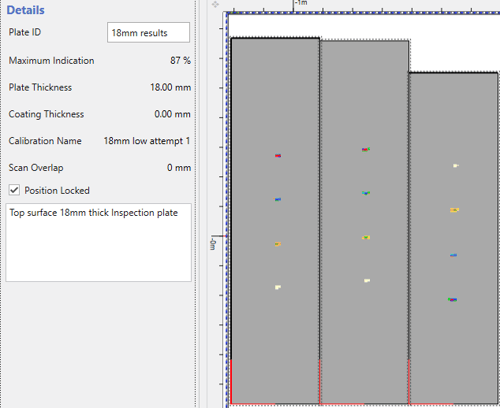

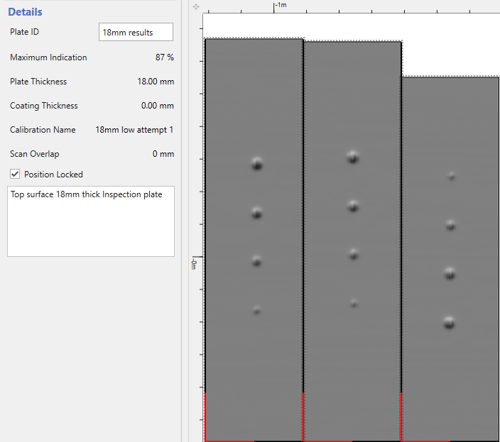

The figures below display FloormapX responses during the inspection of 18mm thick carbon steel floor plates. The plates have four machined defects with depths of 20%, 40%, 60%, and 80%, located on the top surface of the sample. Figures 1 and 2 show the MFL and STARS responses achieved. STARS (surface topology airgap reluctance sensors) is a patented technology developed by Eddyfi Technologies, providing essential surface origin classification and classification technologies.

Figure 1: 18mm top surface response – MFL

Figure 2: 18mm top surface response – STARS

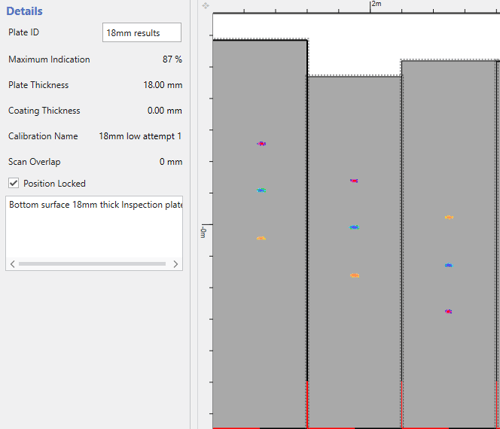

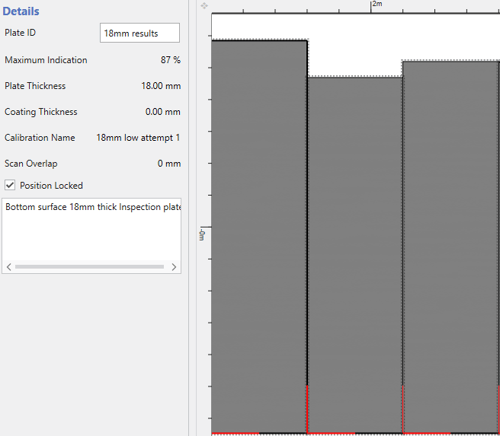

Figure 3 displays the FloormapX MFL and STARS response obtained for bottom surface/soil side indications. In Figure 4, since the defects are on the bottom surface, the STARS response is empty, which greatly enhances confidence in surface origin decisions.

Figure 3: 18mm bottom surface response - MFL

Figure 4: 18mm bottom surface response - STARS

These figures demonstrate how FloormapX enables efficient inspection of 18mm plates with clean data and minimal non-relevant indications. Experienced tank inspectors recognize the importance of high-quality, “clean” data with a large signal-to-noise ratio, as it significantly improves inspection efficiency by reducing prove-up requirements and the time spent on hands and knees.

It is important to consider the performance of inspection equipment within the common plate thickness range of 6mm (0.25in) to 12mm (0.5in). Ideally, the equipment should operate within this range as it ensures optimal probability of detection and minimizes real-world factors that could affect data quality and reporting thresholds. With advancements in tank floor scanning systems, today’s MFL technology comfortably accommodates plate thicknesses up to 12mm (0.5in), extending the operational comfort. This expanded range allows for optimal detection thresholds and easy accommodation of factors like coatings during inspections.

Through thick or thin, we’ve got you

The FloormapX tank floor scanner comfortably handles more "traditional" inspections on plate thicknesses of 12mm (0.5in) and below, aligning with the advanced MFL-based tank floor scanners' comfort zone. But in true Beyond Current fashion, it extends the inspection capabilities for thick plate surfaces, revolutionizing the industry by enabling highly efficient inspections with the highest probability of detection. This advanced scanner handling plate thicknesses up to 18mm (0.7in) represents a significant breakthrough. Inspectors can confidently assess tanks of any location, benefiting from unrivaled signal processing capabilities and extensive tank floor inspection experience offered by Eddyfi Technologies. We have a feeling that you and the FloormapX are going to be as thick as thieves... get in touch to discuss the ultimate solution for thick tank floor plate inspection today! Not ready to talk? No problem, get access to instant pricing here.

Authors: Andrew Simpson, Matthew Boat