A big proportion of heat exchangers in the industry are made from carbon steel tubing, and that carbon steel is prone to the apparition of pits and other defects caused by corrosion, in the free span and near or under support plates.

Missing the detection and characterization of key defects in heat exchanger tube bundles can prolong costly factory shutdowns during routine maintenance at petrochemical plants. Even worse, unfound flaws can cause an unexpected shutdown during production.

Remote-field testing technology is one of the standard technologies used in the petrochemical industry to inspect heat exchangers – however, one key drawback of conventional RFT is the region of insensitivity, or “blind zone”, near support plates and tube sheets.

Due to the nature of the electromagnetic field generated by the probe, the support plates block field penetration through the tube as the probe passes under the support. When corrosion or pitting occurs near these supports, the signal becomes masked, and the defects can be missed even by experienced analysts. If the corrosion or pitting exceeds the tolerance threshold required by the plant, then corroded and even leaking tubes might be put back into service at the cost of reduced efficiency and could potentially cause further problems down the line.

The solution? Eddyfi Technologies’ new remote-field array (RFA) technology helps increase the analyst’s confidence in defect detection and characterization near support plates and tube sheets using visual C-scans.

Figure 1: Ectane® 3 with new remote-field array probe

The C-scan available with the RFA probe creates a visual scan around the circumference of the tube, revealing additional information about defects near support plates and tubesheets that are otherwise not clearly seen on conventional RFT strip charts.

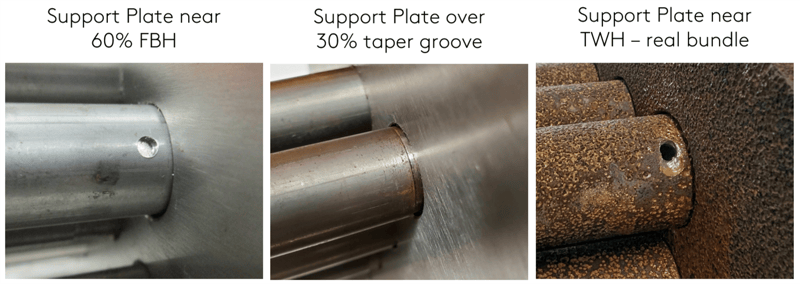

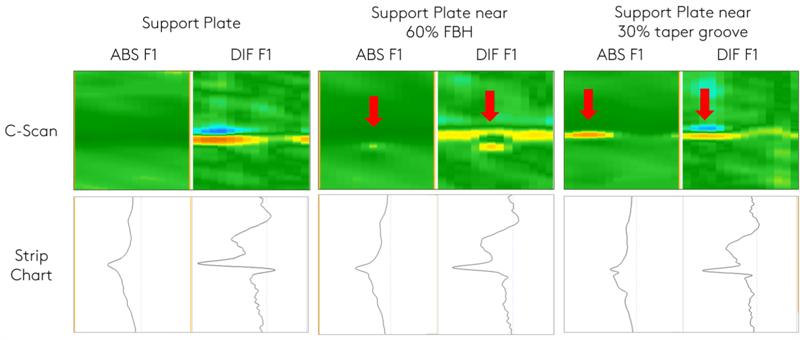

To demonstrate this capability, two 0.75”x0.083” carbon steel tubes in a mock-up bundle with machined defects (a 60% flat-bottom hole and 30% OD circumferential taper groove) and a moveable support plate, along with a real tube bundle with a manufactured through-wall hole were scanned using conventional RFT as well as RFA. A comparison of the strip charts and C-scans for absolute and differential channels is shown below for the support plate and defects.

Figure 2: RFT and RFA data results compared on mock-up

In the case without a defect, the absolute C-scan shows a region of dark green around the support plate, and the differential signal shows a positive-to-negative transition, as expected.

When the support plate is moved near a 60% flat-bottom hole, the conventional RFT differential strip chart shows a very slight change in amplitude, but the result is clear on the RFA C-scan: a defect is visible on the absolute channel, and this is confirmed by the very clear indication shown on the differential channel.

When the support plate almost completely overlaps a 30% circumferential taper groove, a similar result is seen. The RFT absolute strip chart shows a slight change from the typical support plate signal, but this detail might go unnoticed even by an experienced analyst – especially when assessing a large volume of data. On the other hand, the RFA C-scan shows a prominent signal on the absolute C-scan that is difficult to ignore.

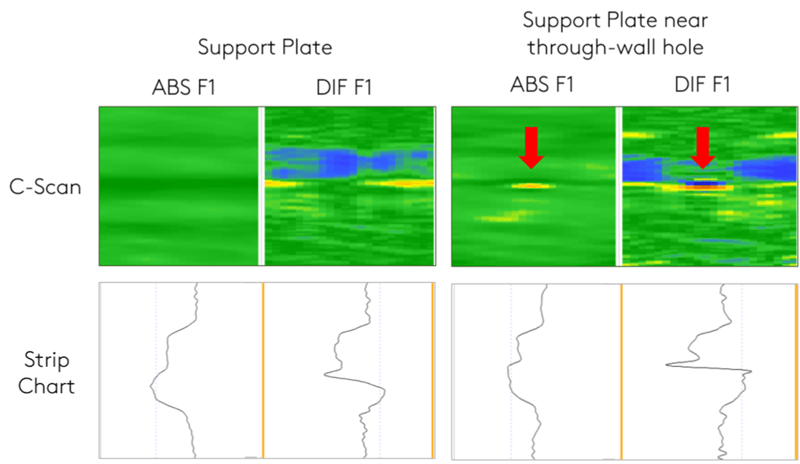

The nominal support plate signal exhibits the same characteristics on a tube bundle used in real field conditions as those of the mock-up. The strip chart signals for the support plate with a machined through-wall hole do not show a major difference from the nominal support plate signal. However, we again see a prominent signal on both the absolute and differential C-scan signals showing the indication.

Figure 3: RFT and RFA results compared on real example from field

The benefits of the new family of remote-field array probes are obvious, boosting your confidence in the detection of critical defects around blind zones and contributing to the successful detection of defects during a time-sensitive plant shut down. Learn more about RFA technology for ferrous tubing inspections here.

Get the most out of your RFA probe with Eddyfi Technologies' new e-learning module.

Employing the use of RFA technology shows an asset’s true colors, and Ectane® 3 is the industry reference as the most advanced surface array and tube inspection test instrument. Get in touch with us to discover how to leverage this technology in your next inspection campaign and stay Beyond Current!

Authors: Laura Burchell, Sébastien Savard