With its versatility and resilience to find corrosion under insulation without stripping it, pulsed eddy current, or PEC, has become the go-to technology to address this challenge. Over the last five years, the introduction of dynamic scanning, array sensors, clever gridding tools, and fast reporting by Eddyfi Technologies has truly transformed PEC inspections with a twentyfold increase in productivity. This article demonstrates the Beyond Current differentiator to stay ahead of corrosion under insulation.

Corrosion under insulation, or CUI, is a well known and documented phenomenon that occurs in insulated pipes and pressure vessels. Growing hidden from sight, this pernicious problem is a plague for any facility with many insulated assets be they housing crude oil on a refinery, carrying hot steam in a power plant or cold ammonia in a chemical plant. Fortunately, NDT tools are available to assess CUI without stripping assets from their insulation and weather jackets. Pulsed eddy current has become the premier tool to address the challenge of in-service CUI inspection.

PEC uses a magnetic pulse to magnetize the bulk of the wall of the component, inducing eddy currents in the part. By listening to the decay of the secondary magnetic field, it can be used to measure the remaining wall thickness without the high costs associated with removing insulation.

Eddyfi engineers strive to push the boundaries of NDT and know that there is more to an inspection than simply the magic moment when the instrument acquires data to show what your eyes cannot see. The Lyft® revolutionizes how PEC inspections are performed from the moment you turn on the user-friendly instrument through to delivery of the end report to your happy customer.

The inspection starts with the component definition and setup creation which is simple and straightforward in the Lyft GO software. These steps are completed in just a minute or two thanks to automatic probe recognition, built-in lists for pipes sizes, and a pre-set scan pattern that ensures you achieve the optimal coverage and resolution essential for a good PEC inspection.

With older generation PEC systems effectively limited to point-by-point measurements (also known as Grid Mode) would then come the awful step of gridding the asset. This means using a paint marker, tape, or another method to draw a reference X-Y grid for the inspection. This step is often longer than the inspection itself! We addressed this issue with a series of key innovations. The Lyft is the first system to offer an effective dynamic mode. By using a high precision encoder to trigger the acquisition instead of a button, Lyft effectively eliminates the need to grid lines perpendicular to the scan axis, drastically reducing the gridding and inspection time by a factor of 2x!

Doubling productivity is nice, but not enough to claim a revolution in CUI assessment. Eddyfi Technologies also introduced the first and what remains the only PEC system on the market with support for simultaneous PEC Array acquisition. The Pulsed Eddy Current Array, or PECA™, probe pulses and acquires on 6 channels simultaneously covering 457 millimeters (18 inches) for a significantly higher gain in productivity. On top of that, the trademarked Grid-As-U-Go™ creates the next reference line as the technician scans the pipe effectively eliminating the need for gridding. The compounding effect of these improvements add an increase in productivity of up to tenfold over scanning in dynamic mode with a mono-element probe. The gain is 20x versus the grid mode! Such claims are exposed in the following time-lapse where the PECA is put to the test against dynamic and grid scanning with mono-element probes.

The PECA probe has impressive productivity and yet the benefits don’t stop there. The array of sensors in the probe are better shielded from surrounding electromagnetic noise and from the influence of interfering components, providing better signal-to-noise ratio, or SNR, than conventional PEC probes.

To further increase data quality, a small part of productivity is often traded for a significant increase in resolution. PECA allows inspection of assets with higher resolution in much less time than with older generation PEC systems. The higher resolution provides increased confidence when making calls to strip insulation or not on mission critical assets.

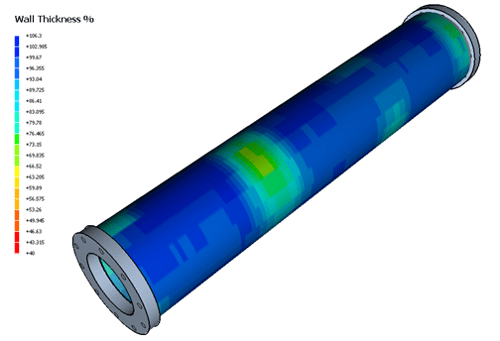

But the work does not stop when the technician leaves the job site. Using the desktop software Lyft CPN, inspectors have access to the best analysis tools to make accurate, reliable calls in a matter of minutes. The analyzed data can then be imported in a SurfacePRO 3D template to create a compelling report with 3D models that the asset owner can easily interpret and ultimately make better decisions.

In conclusion, Eddyfi Technologies’ take on pulsed eddy current goes beyond the technology itself; it is a complete solution that ensures better productivity, better data, and a better inspection report. The workflow is optimized to maximize your time from when you arrive onsite until the report reaches the customer. It gives CUI inspection services a competitive edge unmatched by other screening methods. It is no surprise that Lyft PEC technology is now being deployed to address corrosion challenges more efficiently in other industries. From the decks of military ships to the furnaces of aluminum mills, Eddyfi Technologies’ advanced solution uncovers previously hidden corrosion enabling cost-effective preventive maintenance and keeping you Beyond Current.

Contact our NDT experts to discuss your next inspection challenge today!