Scorpion 2 offers a unique 5MHz dry coupled UT probe, and the patented wheel probe has significant benefits when incorporated in remotely operated inspection robots. Conventional ultrasonic probes require constant coupling to transfer the ultrasonic beam from the probe into the test item. This couplant is usually water or gel. The benefit of dry coupled technology eliminates the need for pumping couplant to the probe which is typically difficult when crawling vertically on an aboveground storage tank. The Scorpion 2, comprising only three main components—crawler, instrument, and umbilical/tether—offers unparalleled portability in the market.

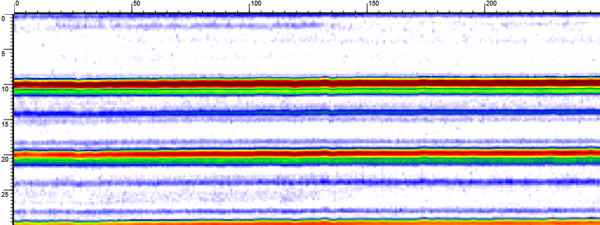

Balancing the signal-to-noise ratio (SNR) is crucial for optimal inspections. The Scorpion 2, with its 5MHz frequency, strikes a harmonious balance between depth of penetration and resolution. In order to show the comparison of the 5MHz probe on varying thickness, we completed a feasibility study on various components and material thicknesses utilizing the system with UT travelling through the 50-meter (164-foot) umbilical. Each of the reference samples for this test were non-coated. Typical storage tank walls range in thickness between 6 and ~40 millimeters (0.234 and 1.574 inches) but naturally we went Beyond Current standards to push the boundaries and demonstrate this probe’s capability. Witness the results:

|

|

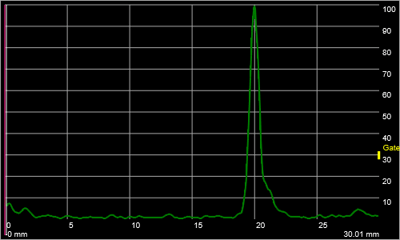

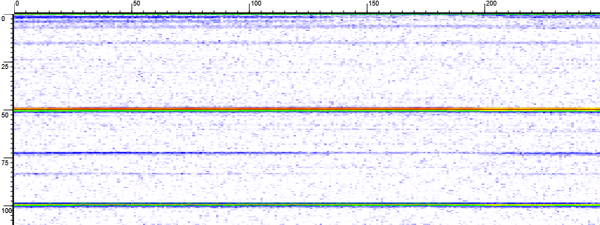

10mm (0.393in) wall thickness – strong and clean response.

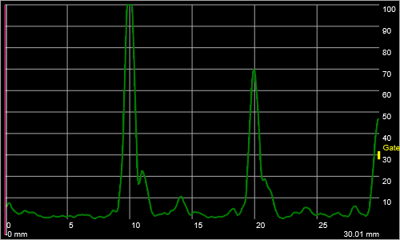

|

|

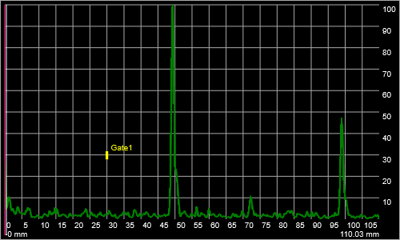

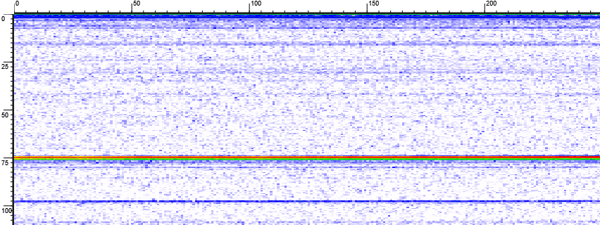

20mm (0.787in) wall thickness – strong and clean response.

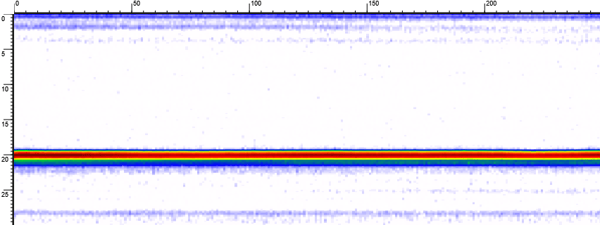

|

|

50mm (1.968in) wall thickness – a small amount of noise but still a strong and clear response.

|

|

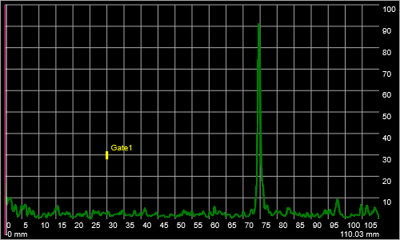

75mm (2.952in) wall thickness – some noise but excellent SNR for this wall thickness.

As with all non-destructive testing inspection methods, ultrasonic corrosion assessment can be improved by optimizing equipment selection. The dry coupled wheel probe that attaches to the Scorpion 2 crawler has a proven track record for assessing corrosion found on storage tanks and other large assets. The supplied 5MHz crystal is universally recognized as the most versatile probe and as the scans above suggest, whether testing thin or thick material with fine areas of corrosion, the performance and data quality is retained. Check out this blog to learn how to roll on to better tank inspection data and decision making.

Eddyfi Technologies is your true one-stop phased array ultrasonic testing shop offering everything from standard and custom probes and scanners to instruments like TOPAZ® and Gekko® trusted by industry leaders worldwide. Contact our friendly experts to discuss your requirements today!