Most Phased Array Ultrasonic Testing (PAUT) or Total Focusing Method (TFM) inspections are carried out using linear array probes. They allow electronic scanning and sectorial scanning in the active plane by applying time delays to the various elements of the probe.

Sometimes, accessibility can be an issue and inspections need to be done without the ability to position the probe in the right plane. In these cases, a matrix array probe is beneficial as it offers steering capabilities in both active and passive planes.

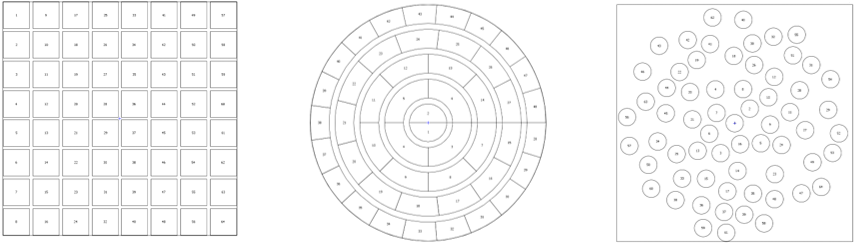

2D ultrasonic arrays are PAUT probes with elements distributed along two directions. Elements can be distributed evenly in a cartesian coordinate system (matrix), evenly in a polar coordinate system (sectorial annular) or distributed randomly. These probes can be used in a pulse/echo configuration and in a transmit/receive configuration for the inspection of coarse grain materials. Examples of 2D array probes are shown in the following figure.

Left to Right: Matrix, Sectorial Annular, Random

The most common 2D arrays are matrix arrays as they are easier to manufacture; we find them extensively in DMA (Dual Matrix Array) configuration for the inspection of stainless steel, for example.

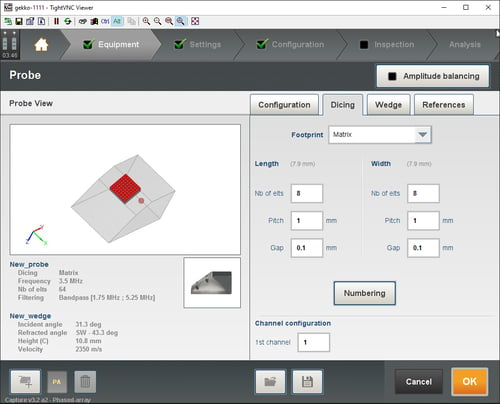

With Capture™ software, it is possible to define and handle matrix arrays. The following image shows the configuration panel used to define an 8x8mm (0.3x0.3in) matrix array with a pitch of 1mm (0.04in) along both directions. When dealing with linear arrays, operators need to pay attention to where the first element sits on the wedge when calculating delay laws. For matrix arrays, it is also important to specify how the elements are being addressed along both directions. In the example below, elements 1 through 8 are along the passive plane, not the active plane. The Capture interface enables addressing the elements in any direction by simply using the symmetry tools.

The main advantage of 2D array probes is being able to perform a full 3D volumetric inspection. By applying proper delay laws, it is possible to steer the energy off the active plane and thus look for defects with particular orientations. It is helpful when access is limited and energy needs to be sent in a specific direction.

When dealing with matrix arrays, Capture offers the possibility to adjust the skew angle. The following video shows a 35-75 degree sectorial scan along the active plane, with a skew of +10 degrees and also a series of three sectorial scans along three various planes.

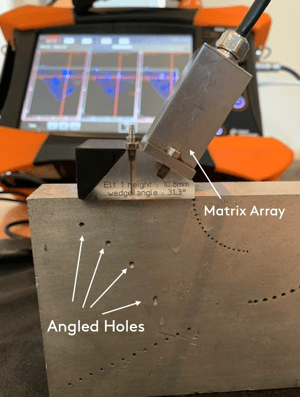

To illustrate this capability, we look at the angled holes in the phased array Type B mockup. These holes are 1.5mm (0.06in) through side-drilled holes (SDH) machined at 30, 45, 60 and 75 degrees.

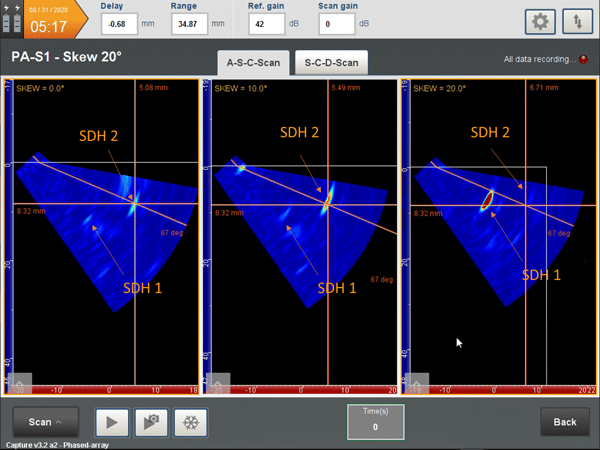

With Capture, we perform a 35 to 75 degree sectorial scan along three planes with skew angles of 0, 10 and 20 degrees. Each skew angle is seen as another group by Capture; thus it is possible to choose a layout with views (A-scan, S-scan, C-scan, etc.) associated to each skew angle. The following image shows the S-scans for each of the planes (0, 10 and 20 degrees) with the angle of the planes indicated in the top left corner of the view.

We can see that the first SDH is seen best with the 20 degree skew angle while the second SDH is seen better with the 10 degree skew angle. By selecting the proper skew angles, it is possible to optimize the sensitivity of detection of the various SDH.

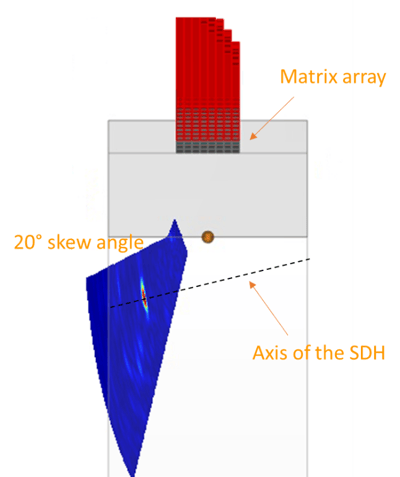

The following image shows the sectorial scan for the 20 degree skew angle in 3D. We can see that the sectorial scan is not contained along the active plane. The 3D data export shows two of the angled holes in the Type B mockup. We can see clearly that the two holes have been machined through the block with two different angles.

Matrix arrays is a great solution when access is an issue or when one need to look for defects with various orientations. Capture software makes it easier to define and use these probes, from element numbering to delay law calculation or Time Corrected Gain (TCG). Did you know that we sell PAUT probes and wedges in our web store? Check it out!

Eddyfi Technologies offers the advanced NDT solutions to ensure that you’re getting the whole picture during your inspection operations. Stay Beyond Current and contact us to learn more about our M2M Gekko®, Mantis™ and Panther™ PAUT instruments that best leverage matrix array probes today.