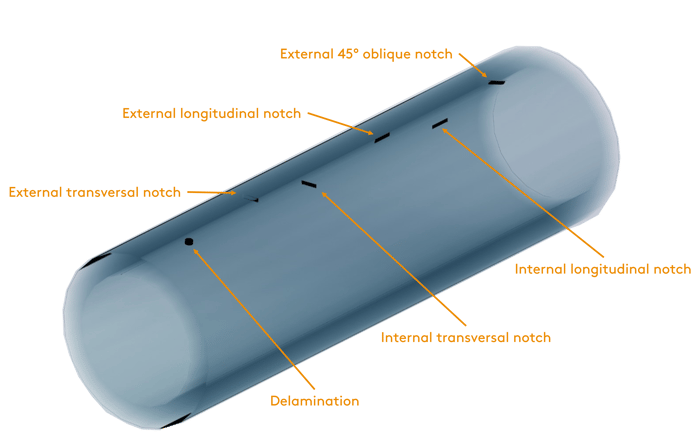

Most standards for ultrasonic testing (UT) of seamless pipe require the inspection of the following defect types:

- Emerging longitudinal cracks (parallel to pipe axis), from internal and external surface

- Emerging transversal cracks (in the circumference of the pipe), from internal and external surface

- Lamination defects (parallel to the surface) and pipe wall thickness variations.

In addition to these typical standards, oblique flaw testing for one or multiple defect orientations is recommended or required by international state-of-the-art standards for oil country tubular goods, more commonly referred to as OCTG, and line pipe testing.

High sensitivity, repeatability, and productivity of the UT testing system are key features for customers producing OCTG and line pipes. Depending on the inspection requirements, UT testing machines linear with rotational transport systems can be used - especially phased array technology which has demonstrated its capability to cope with the high-performance requirements previously mentioned.

For many years, Eddyfi Technologies’ phased array electronics have been used in industries requiring fast UT pipe inspection. Thanks to powerful software, multiple parallel beam features, and improved signal-to-noise ratio (SNR) capabilities, operators benefit from high repeatability and test sensitivity for trusted inspection results. The advanced Panther phased array electronics’ capacity to apply and compute eight beams in parallel (multiple beams or full parallel mode) allows for dramatically improved inspection speeds.

In function of needs for inspection speed, pipe geometry, and defects, one probe can be connected to one Panther per each defect type. Where the element number allows, multiple probes can be connected to one Panther using a splitter.

For standards dealing with classic defect types for UT inspection, the following basic setup can usually be used:

- One probe for:

- transversal defect inspection in forward direction

- transversal defect inspection in backward direction

- wall thickness and lamination.

- One probe for longitudinal defect inspection in clockwise direction.

- One probe for longitudinal defect inspection in counterclockwise direction.

In this case, the final testing speed is determined by cycling the first probe which has to manage three testing tasks with a high number of shots.

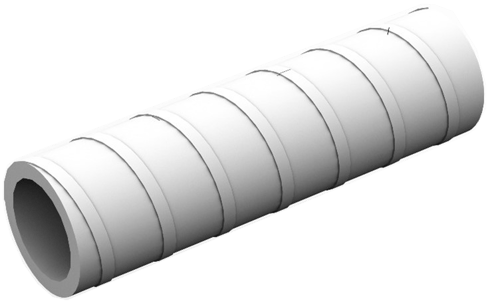

Each probe inspects a width dependent on the number of probe elements, pitch, and aperture size. While the pipe is rotated, the probes move axially to generate a helical scan path along the entire pipe length.

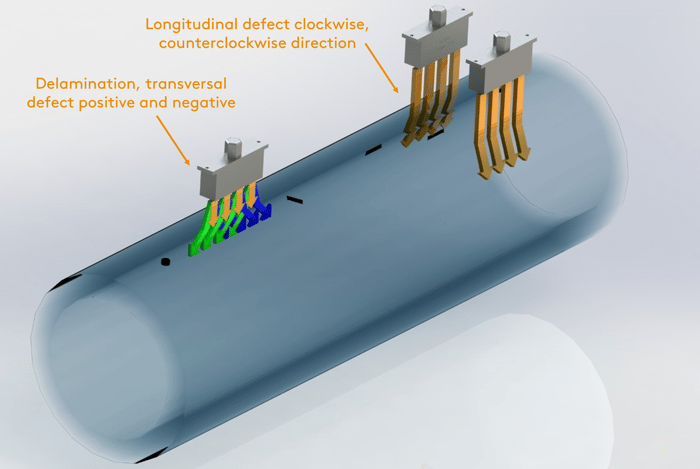

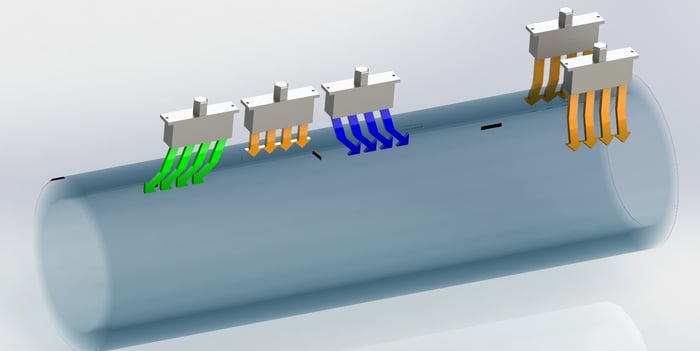

For standards that address classic defect types for UT inspection, the following basic setup is used to allow high test speeds:

- One probe for wall thickness measurement and lamination inspection

- One probe for transversal defect inspection in forward direction

- One probe for transversal defect inspection in backward direction

- One probe for longitudinal defect inspection in clockwise direction

- One probe for longitudinal defect inspection in counterclockwise direction.

As shown in the image below, one probe is used for each inspection task to allow faster cycling. The testing speed can be improved further thanks to the capability of the Panther to compute eight beams in parallel or full parallel mode.

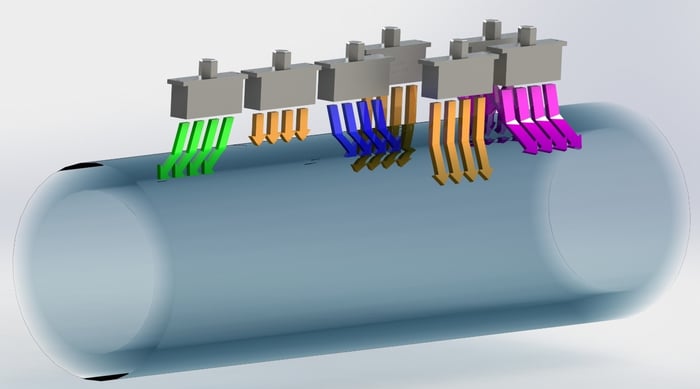

In order to meet standard requirements for OCTG and line pipe inspection, additional probes must be used for oblique flaw testing where the number is limited to a few angles.

A typical setup is as follows:

- One probe for wall thickness measurement and lamination inspection

- One probe for transversal defect inspection in forward direction

- One probe for transversal defect inspection in backward direction

- One probe for longitudinal defect inspection in clockwise direction

- One probe for longitudinal defect inspection in counterclockwise direction

- One probe for oblique defect inspection in clockwise direction for a certain oblique flaw angle range

- One probe for oblique defect inspection in counterclockwise direction for the same oblique flaw angle range as line 6.

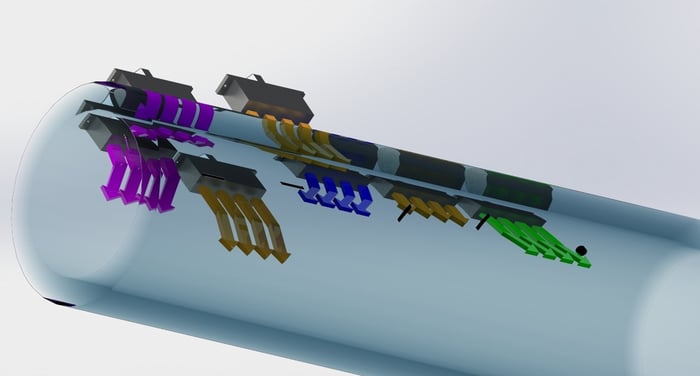

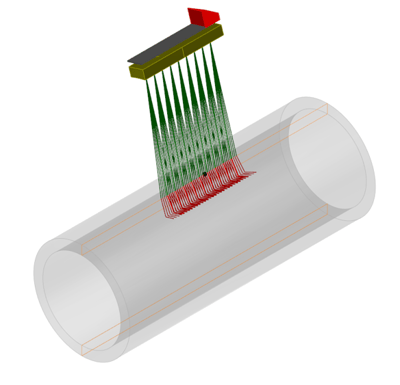

The inspection of the oblique flaw angles is performed by a combination of mechanical probe angles and electronic steering. Each probe is able to cover a certain range of specific oblique flaw angles limited by the mechanical angle, pipe size, and wall thickness. The total number of probes finally depends on the customer requirements, i.e., number of oblique flaw angles. The cycling time and test speed is determined by the number of oblique flaws covered by one probe. It is expected that the demands on oblique flaw testing will increase in the future.

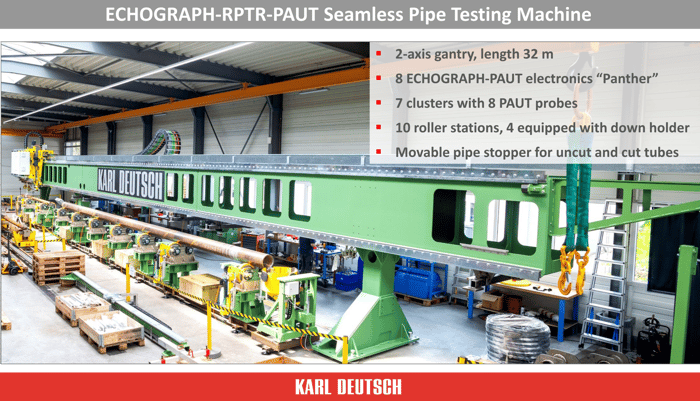

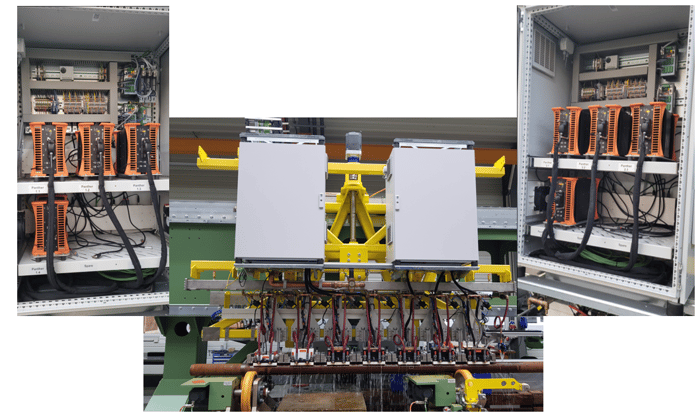

KARL DEUTSCH, a faithful integrator partner of Eddyfi Technologies (and formerly M2M) for many years, developed and successfully commissioned a fully automated phased array ultrasonic testing machine for seamless pipe inspection capable of inspecting a wide range of oblique notch angles on the inner and outer surface of pipes. The machine has high throughput capabilities, inspecting pipes up to two meters per second with a wide helix step.

The machine is equipped with eight Panther instruments working in parallel to evaluate the ultrasonic signals according to flaw type and position. Each Panther is connected to one phased array probe installed in a probe holder. In addition to “classic” longitudinal, transverse notch detection, wall thickness, and lamination detection, multiple probe holders enable the detection of oblique notches from +75 to -75 degrees in both directions (clockwise/counterclockwise).

Figure 1: Gantry with probe holders and cabinets sheltering Panther instruments

The Panther electronics enable applying several shots with different steering angles and computing multiple reconstruction angles in parallel according to the given configuration.

Figure 2: Probe setup for oblique flaw testing using multiple reconstructions

Figure 2: Probe setup for oblique flaw testing using multiple reconstructions

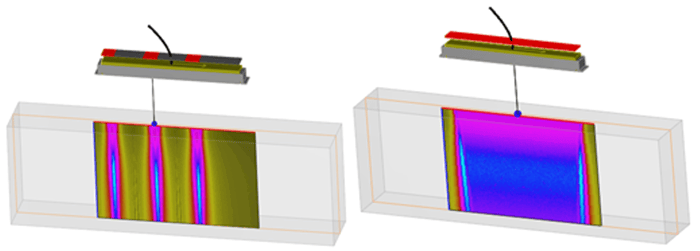

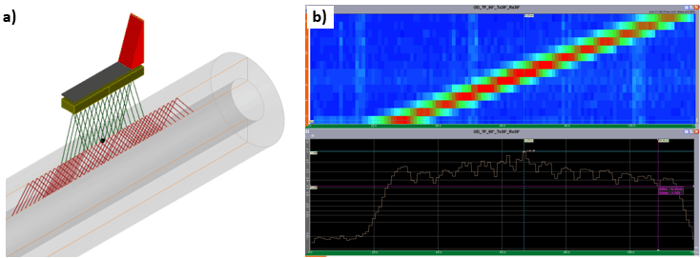

For transverse flaw and lamination testing as well as for wall thickness measurement, the Panther electronics enable firing multiple virtual probes in parallel. This allows reducing the PRF while keeping productivity requirements and saving one transverse testing probe by keeping the required productivity requirements.

Figure 3: Transverse flaw detection with phased array a) Electronic steering in forward and backward directions using 14 shots each, b) Example of ripple in axial scan direction for OD transverse notch

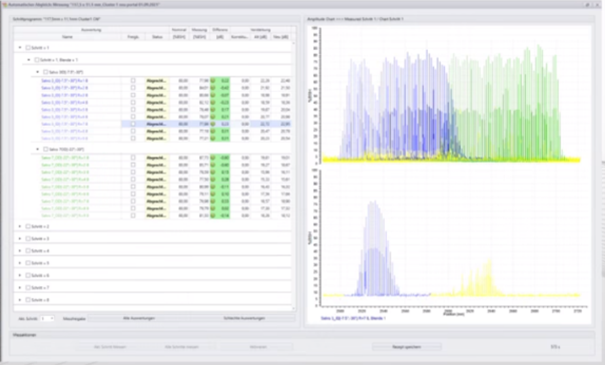

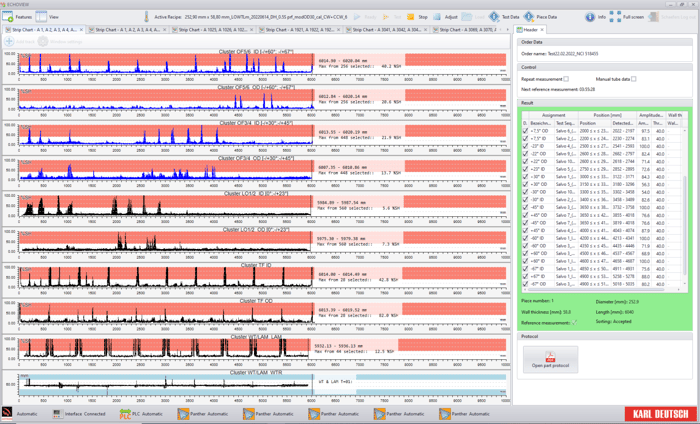

As this kind of machine can be complex for user to manage, KARL DEUTSCH has developed a powerful supervisor software interfaced with Eddyfi Acquire software using remote SDK. It gets several million of gates results per second at 1 m/s rotation speed.

It manages automatic calibration, setup, sensitivity balancing and acquiring data in real time to do automated pipe health evaluation and report.

Figure 4: Calibration/Sensitivity balancing tool

Furthermore, the KARL DEUTSCH software combines and displays the inspection results of all probes in a strip chart view to allow post-processing of the results.

Figure 5: Graphic display of multiple probe inspection (calibration pipe) for ID and OD defects 0° to +75°, 90°, and Lam as well as lamination measurement

When it comes to ultra-fast seamless pipe inspection, the Panther clearly delivers seamless results. Just imagine what the fastest and most versatile phased array and total focusing method machine can do for your inspection operations. Why not get in touch with our NDT experts today to discuss keeping you Beyond Current on the next job? And don’t forget to subscribe to our blog to receive the next one direct to your inbox!