Ultrasonic testing (UT) is regarded as the most accurate non-destructive testing (NDT) method for locating corrosion and providing measurements for remaining wall thickness and corrosion depth. This UT information feeds into integrity management systems, and engineers can determine the fitness-for-service and remaining life of components.

Conventional UT can only provide a certain level of component coverage and is typically only used on spot readings at thickness measurement locations (TML) where corrosion rates are calculated at a known and consistent location. Although this information is invaluable for engineers, there is always the concern of missing defects. Corrosion can manifest itself in many morphologies and many industry trials have shown that conventional UT is not suitable for 100% coverage of the component.

With this in consideration, automated UT systems have become increasingly popular for asset integrity assessment and by using Phased Array our customers can maximize productivity without compromising on data quality or resolution. Automated systems can provide full coverage, and with the Eddyfi corrosion mapping packages, there are software features that assist in automatic defect recognition.

Eddyfi Technologies recognizes that corrosion mapping is a significant industry and have developed a series of solution packages that suit our customer technical requirements and also budget. We understand that one solution is not suitable for all situations and this article illustrates the various packages we offer.

Corrosion mapping is typically offered in two distinct forms: semi-automated encoded or fully automated. Semi-automated encoded scanners are often less expensive, portable —and although they are manually operated— still provide fully recordable data sets. Semi-automated operated scanners are usually the preferred choice when access is suitable and for pipework and vessels. Fully automated systems are robotic crawlers that have pre-set scanning sequences within the software, therefore removing the manual requirements for data collection. Automated systems are usually preferred for large assets such as storage tanks and larger vessels.

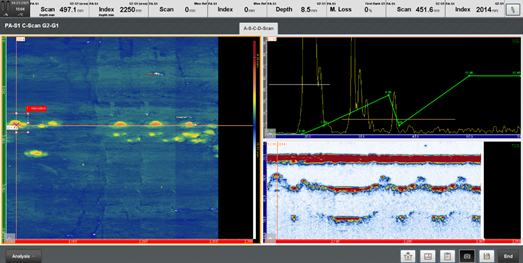

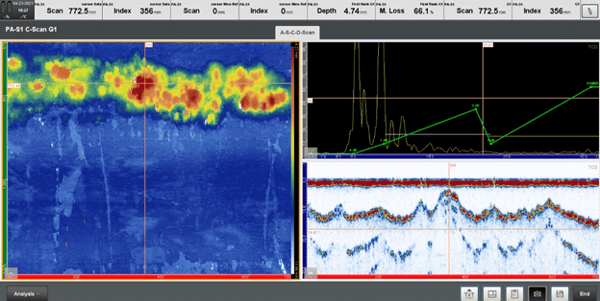

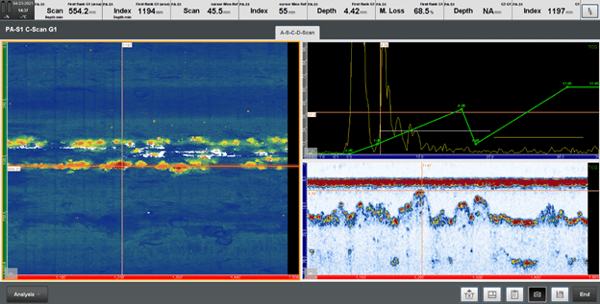

The phased array corrosion mapping solutions from Eddyfi Technologies come in two different applications, these include contact testing and immersion waterbox (Aqualock). The contact type method utilizes a dual linear array (DLA) probe, often selected for its near surface resolution capabilities. Aqualock has been designed with improved water flow, consistent and linear interface response. These options can feature in both a semi-automated and automated capacity.

Sweeper

This is the entry level phased array corrosion mapping solution from Eddyfi Technologies. It is a two-axis semi-automated encoded scanner that provides the capability for seamless 2D mapping for one-person operation. The Sweeper has an ergonomic body, quick-release probe holder, braking system, and also has weld inspection capability. This one-handed solution is ideal for small area corrosion mapping, and can work from 100-millimeter (4-inch) outside diameter to flat plate, our customers use this versatile scanner for pipework, targeted areas of large components, dome end inspection, or areas of restricted access.

LYNCS CM

The LYNCS™ CM is also a semi-automated encoded scanner, but this system provides 2-axis data collection utilizing the rail system. Perfect for larger area coverage and deployable via rope access.

The operator has the ability to collect 500 millimeters (20 inches) of axial coverage per probe placement so has increased productivity for straight sections of pipe or grid collection on vessels. The LYNCS CM has been designed with consideration to many years of field experience and has subtle features that we know benefit the technician in the field. Also built with breaks, the LYNCS CM has rope access deployment benefits and integrated user controls. The real benefit of LYNCS CM is that the Aqualock is centrally mounted between the magnetic tractors which means that setup time is almost eliminated. Users can move from 100-mm (4-in) pipe to any other diameter, and the probe will automatically be normal to the scanning surface.

Automated Phased Array Corrosion Mapping Solution

.jpg?width=484&height=321&name=NAVIC-Tank1%20(1).jpg)

The Eddyfi Technologies Automated Solution is an evolution of the well-established RMS2 scanner. Building on the success of the original RMS2, Eddyfi's new look offering when paired with the industry leading phased array instruments from its Center of Excellence for PAUT, delivers a best-in-class battery operated-portable solution. This turn-key package boasts versatility through its modular arrangement, capable of high-speed Phased Array (PAUT) corrosion mapping, Conventional corrosion mapping and weld inspection utilizing both PAUT and ToFD probes, perfect for critical integrity assessments of vital assets and a key component of a Non-Intrusive Inspection (NII) campaign. The Eddyfi Technologies Automated corrosion mapping solution is the fastest automated system on the market, available in four various sized raster arms that cover 75-millimeter (3-inch) pipework to flat plate.

At the core of all these systems is the powerful phased array instrumentation from Eddyfi Technologies. These instruments, with the forever evolving Capture™ & Ultravision software platforms, gives customers the option to perform all types of corrosion mapping or simply choose the system that suits the requirements. Both software suites have dedicated features assisting technique setup for corrosion mapping and also analysis tools that provide assisted defect recognition and automatic sizing of corrosion.

The ‘pick a mix’ corrosion mapping suite at Eddyfi Technologies is a perfect block builder and scalable approach for Inspection companies. Customers can select the system that best fits the inspection needs, but also upgrade or interchange between the systems at a reduced purchasing cost and maximizing utilization. Phased array for corrosion mapping has really become the technology of choice. With assisted analysis software, 3D data representation and 1 x 1mm (0.04 x 0.04in) resolution accuracy, the decision making for engineers is that much easier.

If you’re in the market for the best phased array corrosion mapping solution, contact Eddyfi Technologies to have your precise needs paired today and stay Beyond Current!

Authors: Stuart Kenny, Gareth Mugford