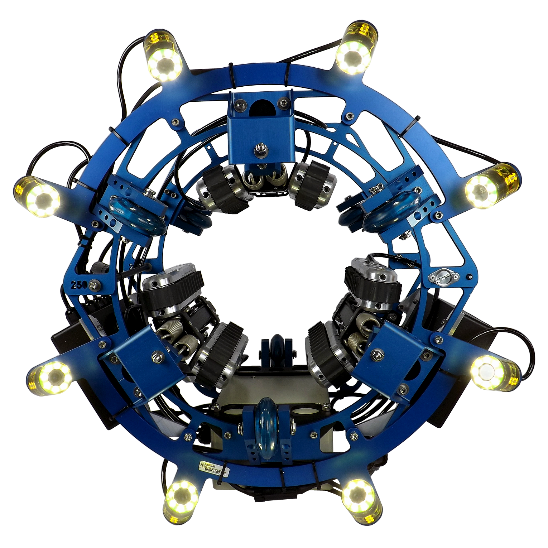

Previously referred to as the Versatrax MicroClimber, this custom robotic solution was developed for the Province of British Columbia to inspect the Port Mann Bridge on Highway 1. Its unique circular design lends itself to piling inspection and cleaning, snow removal, subsea guy wire assessment and cleaning, and any other general external pipe visual inspection and cleaning applications. With a minimum diameter of 160 millimeters, or 6 inches, and a tether length up to 260 meters, or 860 feet, the MicroClimber collects Repeatable, Actionable, Meaningful, and Preventive data (learn more about RAMP results in this free eBook) through real-time photos and video recording.

Equipped with eight fixed focus cameras, this OnSpec custom solution travels up to 9 meters, or 30 feet, a minute on a tracked platform to get an all-inclusive look at current conditions. The compact cameras are encased in an epoxy housing which makes them virtually indestructible, allowing them to operate in the most confined spaces and hazardous environments. Versatile, and resilient, these units offer both heat and chemical resistance. With built-in LED lighting and a high resolution and low lux, this inspection camera is highly effective in very low light environments. Whether used as a drop camera up to great depths, integrated within a crawler system —like here— or ROV, or helmet mounted for topside or third-party surveillance, this camera is a versatile visual inspection solution. It is most often seen as the rear camera used for tether management on Eddyfi Technologies standard crawlers like the VersaTrax™ pipe inspection vehicle.

Nicknamed the ‘night crawler’ by TI Corp’s team, the bridge cable inspection crawler is used for routine assessments of the Port Mann Bridge at night. These structural integrity inspections are performed annually to confirm the remaining useful life of the protective sheathing on the bridge cables. We have to agree with TI Corp – the night crawler is a pretty unique and cool piece of technology to use during highway infrastructure maintenance. See it in action in the following video.

Not limited to remote visual inspection, Eddyfi Technologies offers a range of solutions for advanced inspection technologies including standard robotics for non-destructive testing. Check out this article on bringing bridge inspection to Beyond Current standards.

Beyond inspection, our Center of Excellence for Robotics provides custom solutions for remote industrial operations. If you’re curious about learning how robotics may solve your problem, contact us to discuss your unique challenge today!

.png)