Navigating the Maze: Unique Challenges of Different Pipe Support Geometry

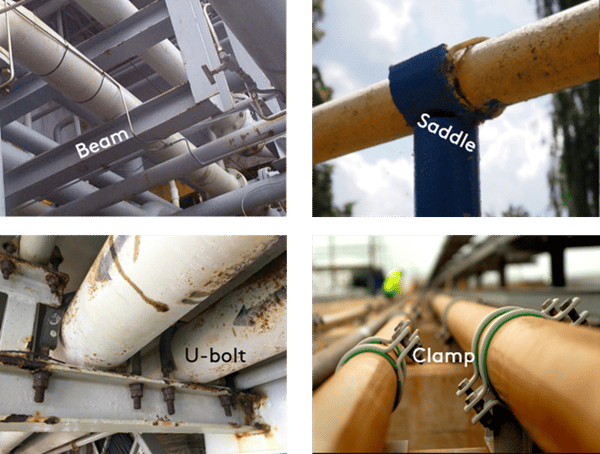

Pipe supports come in different types, each with its own set of unique challenges due to their geometry. One common type is the simple support, which can be mechanically clamped or simply "resting" on the pipe. These supports, with no welded connection to the pipe, pose a higher risk of corrosion. Their geometry, often in the form of I-Beams or clamps, presents challenges in accessing and inspecting the areas underneath. On the other hand, welded supports provide a stronger connection to the pipe but introduce their own complications. The welded connection can potentially mask wall loss indications, making it trickier to detect corrosion within it. Additionally, the complex geometry of welded supports requires careful consideration to ensure comprehensive inspections. Understanding these different pipe support types and their geometry is crucial in developing effective inspection strategies to combat corrosion and maintain the integrity of the piping system, occasionally requiring complimentary techniques to accommodate differing support geometries. Moreover, factors like access, pipe diameter, and end-user requirements will play a role in determining the most suitable inspection strategy.

Figure 1: Types of Pipe Supports

Unleashing the Sonyks Sleuth: MRUT’s Revolutionary Impact on CUPS Detection

When it comes to small diameter pipes, screening for corrosion under supports is no small feat. Enter medium-range ultrasonic testing (MRUT) with Sonyks™ guided wave inspection equipment. MRUT brings some impressive advantages to the table, including improved resolution, sensitivity, circumferential inspection, and quick deployment when applied using the Sonyks instrument. It's designed specifically for small diameter pipes, making it the go-to screening tool for CUPS. With its ability to work with simple supports like resting and clamps, MRUT simplifies the inspection process, ensuring an efficient inspection.

But let's not ignore the limitations. MRUT can pose challenges when it comes to welded supports, and it is currently limited to smaller diameter pipes. However, there's a solution that revolutionizes the inspection experience—magnetostrictive collars or the Magneto tool by Eddyfi Technologies. These collars offer a mechanical coupling solution, eliminating the need for pneumatic force or adhesive bonding. With their slim profile and portable design, magnetostrictive collars make inspections quick and hassle-free. No more setup time or bulky equipment to deal with.

The advantages of magnetostrictive collars go beyond ease of use. Their broadband data acquisition capability ensures comprehensive analysis of corrosion conditions, leaving no room for missing crucial information during inspections. These collars open up possibilities for inspecting pipes that previously faced radial clearance issues, allowing us to reach those hard-to-reach areas without limitations.

By tuning the collars to high frequencies specifically for CUPS applications, the highest sensitivity and detectability can be achieved, even for small defects representing just 1% of the cross-sectional area. With inspection lengths of up to 10 meters (33 feet), magnetostrictive collars target individual spool lengths and enable thorough examinations of pipes containing numerous features.

What sets Eddyfi Technologies' offering apart is its segmented design, providing enhanced diagnostic capabilities. Unlike non-segmented versions, this unique approach allows for differentiation between reflected axisymmetric and flexural waves, presenting a more detailed diagnosis of defects. With broadband data acquisition and full matrix capture (FMC), inspectors have access to a wide range of frequencies and can reconstruct data in various ways, offering greater flexibility and the ability to monitor frequency-dependent behavior.

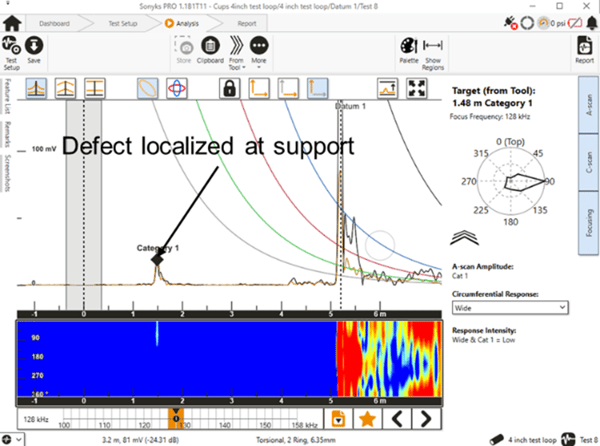

In this example, a 100-millimeter (4-inch) Magneto-tool was positioned approximately 1.5 meters (5 feet) away from a pipe support. Ultrasound was sent into the pipe support in two different conditions, 1. no defect present, and 2. machined corrosion defect introduced.

Figure 2: Test loop in Cambridge

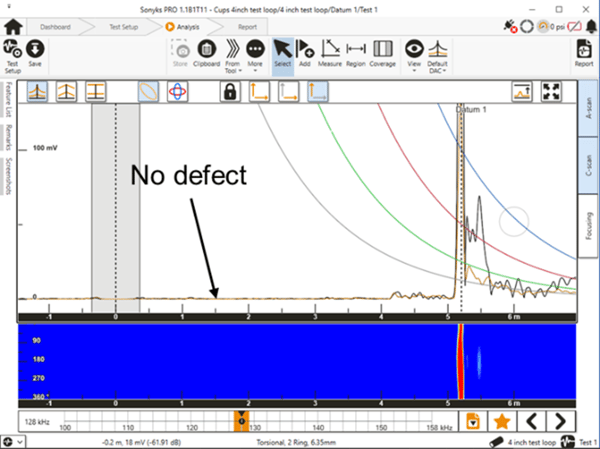

This is the result of the first condition.

Figure 3: No defect scan

And here’s the result with a defect introduced at the U-bolt support. There is a clear signal from the corrosion-like defect at the weld support. Furthermore, the C-scan and focusing show this defect localized at the 90-degree position. It was a mere five minutes to setup and run this test, clearly showing the efficiency of MRUT for CUPS.

Figure 4: Localized defect detected

In summary, the introduction of magnetostrictive collars revolutionizes CUPS inspections, offering improved coupling, portability, size reduction, enhanced diagnostic capabilities, broadband data acquisition, and the power of medium-range ultrasonic testing – learn more about the power of Magneto here.

Contact our team of experts to learn more and subscribe to our blog to receive the latest news direct to your inbox.

Authors: Paul Jackson, Francisco Hernandez-Valle