Customers entering a new non-destructive testing (NDT) market can face a significant number of barriers that can affect quality, productivity, and ultimately, success. Despite becoming more popular year after year, guided wave testing is still a relatively new NDT technology. Compared to other advanced ultrasonic testing (UT) techniques such as phased array ultrasonic testing (PAUT), guided wave testing (GWT) is considered a niche inspection technology. There are many more PAUT systems out there, and therefore many more PAUT technicians available. Experienced GWT technicians can be harder to obtain, making it more challenging to enter into this market.

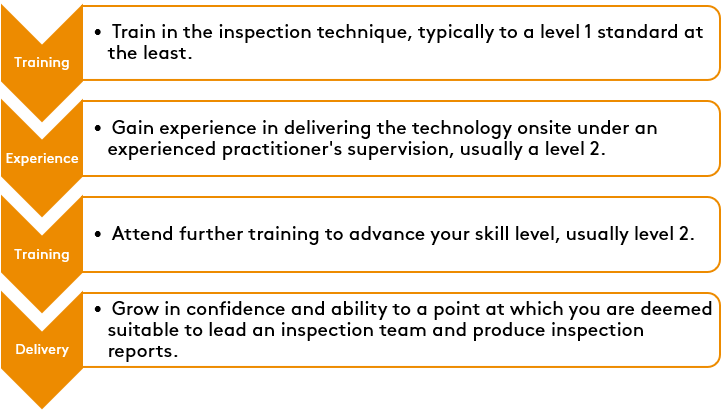

Eddyfi Technologies has identified many of these barriers and have ensured that, where possible, we can mitigate these barriers for customers and potential customers alike. In most cases, companies entering the GWT market are inspection providers looking to increase their inspection portfolio. This may be a result of your client requesting the technology or the requirement for a rapid pipe inspection. You may have also identified GWT as a natural step in your organizational growth. In all cases, you will likely have experienced inspection personnel; however, very few, if any, will have had experience or be certified in GWT. It is advised to follow these steps when learning a new inspection technology.

Figure 1: Ideal Guided Wave Testing Training Model

I was fortunate enough to learn via the above path. I attended an initial GWT training course and then spent several months assisting an experienced practitioner. During this time, I benefited from their experience and expertise. I learned how to prepare, organize, and deliver large-scale GWT inspections. Many of the skills required to do this are not generally covered in NDT training courses. Having a mentoring scheme in place is a great way to ensure knowledge transfer and ongoing quality through final report and data reviews.

What about companies that are just entering the GWT market? They are without experienced GWT operators, so they are unable to use this system. They can attempt to employ GWT trained technicians from other organizations to enable the above scenario. Many companies do this. The alternatives can be restrictive, so Eddyfi Technologies offers customers solutions for these issues. Here are some of the ways we continue to provide unrivalled support.

1. Onsite Training

Many factors influence a successful GWT inspection:

-

Job preparation

-

Pre-mobilization review

-

Scope of work review

-

Project organization and planning

-

Executing the inspection

-

Data handling, storage, and interpretation

-

Final report construction.

Eddyfi Technologies has a team of experienced GWT technicians who can provide onsite training. Upon completion of the standard level 1 GWT training, customers have the option to utilize this service which provides newly trained GWT technicians with an additional dimension to their formal training. Each of our GWT support team members has over ten years of onsite guided wave testing experience, covering a vast range of long-range ultrasonic testing applications. Clients that use this service benefit from fast-tracking newly trained operators to a level that would otherwise take months of onsite experience to achieve.

2. Remote Data Analysis

Remote data analysis is another way to help customers transition into the guided wave market without experienced operators. In this case, the trained technicians go to the work site as usual, collect the guided wave data, and submit it via Eddyfi Technologies’ upload site. To enable accurate interpretation, we ensure that clients provide the essential information with written instructions. This document details all the vital information needed. This information includes:

-

File name format

-

Isometric sketches displaying pipe features in relation to the tooling

-

Digital images

-

Any other information that will assist in this process.

Remote data analysis is an excellent way for clients to gain confidence in their inspectors. Several Eddyfi Technologies customers have used this facility in line with their operator's analysis. This method enables operators to compare their analysis to that of a highly experienced technician. This method is a great substitute for having an onsite physical mentor. Each technician can identify what they are doing right, increase their self-confidence, and be aware of learning opportunities by reviewing the data interpretation files. Remote data analysis is very popular with new clients and used by more experienced clients for advanced GWT applications. Remote data analysis provides clients with a cost-effective service that offers peace of mind when working with inexperienced GWT technicians or with GWT applications not faced before.

3. Level 3 Report Review and Sign Off

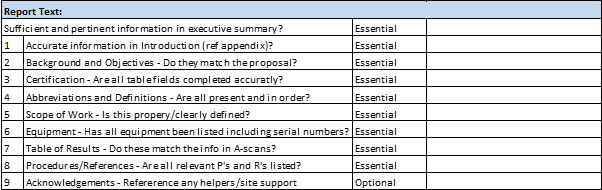

An NDT report will contain all the relevant information collected and interpreted throughout the inspection process. It is vital that this document accurately represents the condition of assets that have been inspected. The report should be clear, consistent, and easy to understand. To ensure quality, a report should always be subject to review before submission. The reviewer should, where possible, be someone who has not had any involvement in the inspection process. The reviewer's job is to ensure that the data has been interpreted accurately and mistakes have not been made. The reviewer's goal is to help the author improve this and future reporting documents. Reading through the report and giving a verbal approval is not a sufficient review. Each review process should be consistent with the last. Therefore, a report reviewer’s checklist should be used as part of this process. The checklist details all the checks required as part of the review process. All of the components included in the checklist need to be signed off before the report is authorized. An example extract from a report review checklist is shown in Figure 2.

Figure 2: Sample Extract from Eddyfi Technologies Report Review Checklist

The checklist is divided into categories such as report text, report data, digital photographs and further detail, isometric sketches (where applicable), and overall report presentation. The reviewer will progress through the checklist and either return the report for correction or approve it for submission. In some cases, clients do not have anyone suitable to conduct this type of review. Eddyfi Technologies ensures clients can have their final reports validated by offering a level 3 report review and sign-off service. This has been popular with many customers. The review process ensures that clients are confident that they are submitting accurate, high-quality reporting documents to their clients whilst providing their GWT technicians with valuable feedback from a level 3 certified GWT technician.

In Conclusion

Eddyfi Technologies is a customer-centric organization; first-class customer support is a core value. When you invest in our product offering, you join an exclusive club. Having strong relationships with our customers is mutually beneficial. We can assist with expert knowledge and assistance, ensuring that you use our products to the highest level for a competitive edge. Assisting clients with services such as those discussed in this blog provides us with valuable information. We can use this information to identify common skill gaps. Reviewing many client reports may highlight a topic or process that clients find challenging. Recognizing this therefore enables us to create a greater emphasis on these topics during our training courses. This 360-feedback loop ensures that we can continually identify skill gaps and spend additional time addressing these items in future training courses.

If you’re interested in taking the next step to improve your pipeline inspection operations, contact us to arrange a demo of the Focus+™ offering rapid assessments with trusted results today!