With newly introduced regulations by the Pipeline Hazardous Materials and Safety Administration, or PHMSA, operators must test all pipelines, even those previously exempt, for maximum allowable operating pressure. The new Gas Mega Rule requires all pipeline operators to report on the totality of their assets including validation of the alloy grade, wall thickness, diameter, material strength properties, and maximum allowable operating pressure of the pipes. If companies are unable to provide PHMSA with traceable records and reports containing this information, they will need to conduct additional testing for further verifications.

The Gas Mega Rule aims at improving the safety laws for onshore gas and hazardous liquid pipelines in the United States, an initiative that has taken a decade of work and review to enforce in 2021 and couldn’t be timelier considering the nation’s pipeline network is operating beyond its intended design life; pipeline integrity threats to the aging infrastructure need to be assessed and reported on to prevent failure and maintain operational safety. To comply with the new regulations, industry will face increasing demand for hydrostatic pressure testing, more in-line inspections of buried transmission lines, and inevitably more dig programs for direct examination. This article highlights the technology best suited to address the PHMSA Gas Mega Rule.

A lot of characteristics can make a pipeline difficult or even impossible to inspect with conventional in-line tools. Among these are small diameter pipes, typically 305 millimeters/12 inches and below, and pipes with varying diameters, small radius bends, connections, or very steep sections. With the new Mega Rule in place, these “unpiggable” lines will be subject to more sampling for investigation. The recent development of specialized tethered tools that can carry in-line inspections over a few miles of otherwise unpiggable pipelines has added more capability for operators to locate sensitive areas for further direct assessment. Another alternative to in-line inspection, the Focus+™ inspects long sections of buried pipes from a static location and measures the distribution of corrosion around its circumference and at a specific distance. This technology is based on pulse-echo guided waves and offers a miniature version of the tool for the inspection of small diameter lines (38 to 152 millimeters/1.5 to 6 inches). Once areas of interest have been targeted, non-destructive examination remains prevalent on these unpiggable pipelines to identify and investigate potential threats related to internal and external corrosion and stress corrosion cracking during direct assessment.

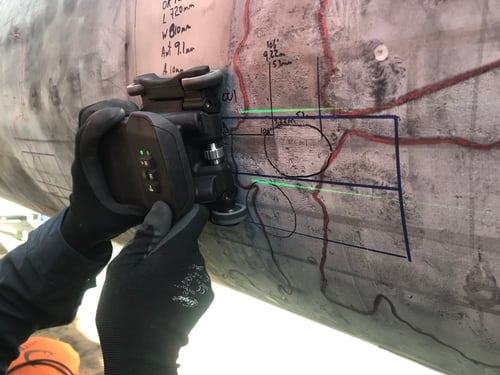

To address stress corrosion cracking, or SCC, Eddyfi Technologies’ Spyne™ can detect any millimeter-sized linear indications breaking the external surface while moving at a speed up to 600 mm/s (24 inch/s) along the axis of the pipe. This technology, based on eddy current array, or ECA, offers a probability of detection for SCC colonies that has been proven to be higher than that of conventional magnetic particle inspection, or MPI. Within only a few minutes, a full pipeline joint can be inspected by Spyne with the exact position of all SCC indications reported for further investigation or repair. For smaller lines, the new Mini-Spyne solves this issue by offering the same high-resolution ECA technology while scanning pipes as small as 50 millimeters/2 inches. It offers the exact same performance (probability of detection, speed, encoded data recording) as its big brother, Spyne, but in a miniaturized embodiment.

Finally, to better characterize the cracks once they have been located, the Sharck HR probe can be used for precise depth sizing up to 3 millimeters/0.120 inches deep.

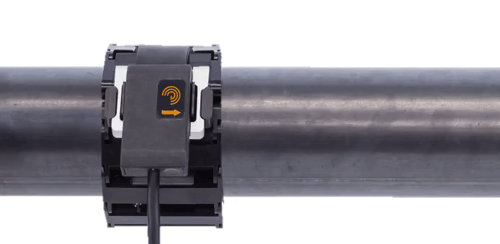

For the rapid detection of corrosion and pitting —both internal and external— the magnetic flux leakage, or MFL, based Pipescan HD™ can also inspect all pipe diameters 50 millimeters/2 inches and greater.

By offering comprehensive and reliable inspection instrumentation with low user-dependency for both regular and unpiggable pipelines, Eddyfi Technologies keeps pipeline operators worldwide Beyond Current by staying on top of ever-changing regulations to ensure the safety of their assets. Contact our team of dedicated experts ready to answer your pipeline integrity challenges today!