TubePro 6, generates high-quality reports faster than ever. The overall software speed has been significantly improved through code optimization, making essential operations —from project loading to PDF generation— up to 40% faster. This optimization particularly benefits large tubesheet maps with over 2,000 tubes, enhancing the efficiency of the entire reporting process.

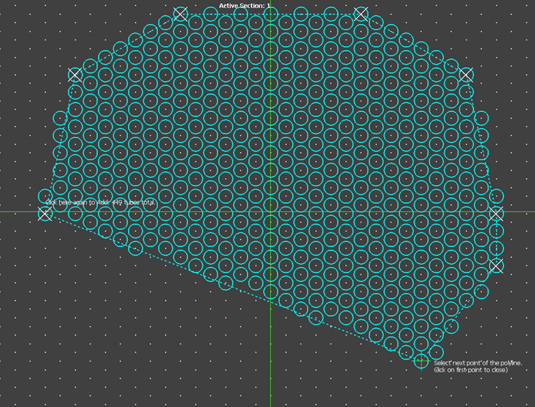

With the addition of the new grid mode feature in tubesheet view, a dynamic improvement to tube mapping process allows users to interactively create and edit tubesheets. This feature not only speeds up the tubesheet creation process but also ensures precise tube alignment. Leveraging the newly implemented shortcuts in this version can also significantly help for quicker creation and modification of tube maps.

The grid mode, coupled with the use of the interactive polygon tube addition tool, ensures precise tube alignment while accelerating the process of creation and modification of tube maps

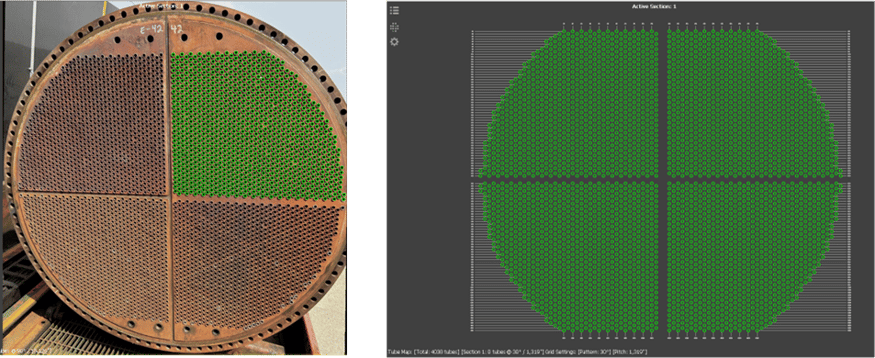

Additionally, the new version includes improved photo detection algorithms, ensuring faster and more accurate alignment of tubes to the closest pattern. The automatic tube alignment feature can further simplify the setup process and saves valuable time for creating tube maps.

TubePro 6 offers faster tubesheet creation with improved photo detection algorithms and a new automatic tube alignment feature to automatically align the tubes to the closest pattern

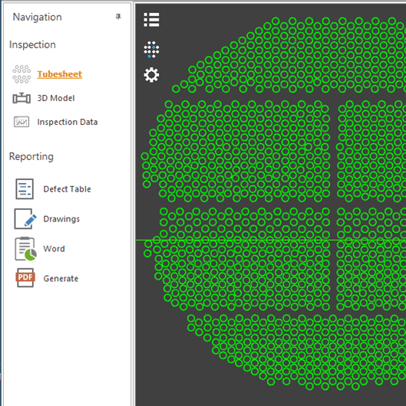

Simpler User Interface: Streamlining Inspection Processes

Stepping into the frontstage view, the navigation panel is thoroughly redesigned to split the workflow into two main sections: Inspection and Reporting. This division aims at enhancing the simplicity of generating report templates while ensuring a more intuitive and efficient process for users as they navigate through each step. This menu provides a comprehensive overview of the essential parts involved in generating the final report. The workflow seamlessly guides users from top to bottom, covering critical tasks such as tubesheet creation and 3D modeling of the heat exchanger, followed by importing inspection data and creating defect tables, drawings, Word, and Excel report templates to generate the final inspection report. Notably, the ribbon menus corresponding to each step actively updates to display relevant tools and functions.

Workflow Division: The redesigned Navigation panel efficiently splits the workflow into two main sections – Inspection and Reporting

TubePro 6 offers a 60% reduction in buttons without compromising functionality. This minimizes the learning curve, enabling new users to become proficient more rapidly, and ensuring a smooth inspection experience for seasoned professionals. This improvement involves a strategic rearrangement of buttons and tools distributed across different menus to provide a more user-friendly experience that aids in understanding and navigating the software seamlessly.

Given the improvements made in this version, the display of tube numbering has been enhanced to adjust dynamically based on the cursor's position, providing improved visualization, particularly beneficial for locating tubes in large bundles with over 2,000 tubes. Additionally, users can also customize the appearance of the tubesheet map to visually differentiate tubes with different wall thickness (WT) and outer diameter (OD). The software's developments are further extended with advanced tube selection tools, allowing users to selectively choose tubes based on specific criteria such as WT and OD.

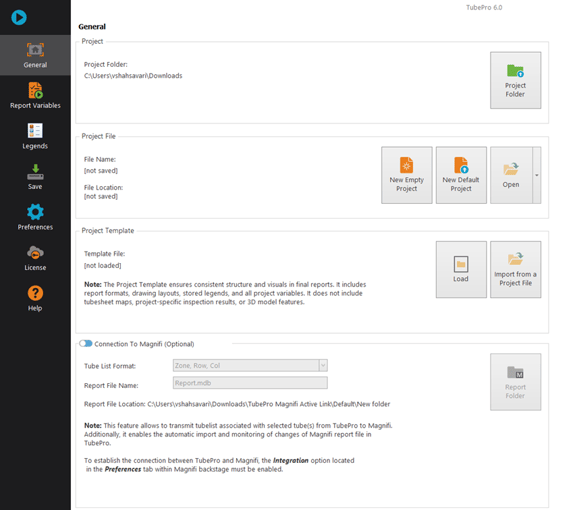

A standout addition to TubePro 6 is the introduction of the backstage. This addition refines the user interface as it delivers a streamlined and cohesive interface skin to that of Eddyfi Magnifi software with the goal of improving the overall user experience.

Like the renowned Magnifi® software, the backstage view in TubePro serves as a centralized hub consolidating all functions associated with project management and global settings. The inclusion of dedicated menus further simplifies various tasks such as the management of report variables, customization of legends, handling preferences, managing imports and exports, configuring connection settings to Magnifi, and more.

Backstage View - a central hub for bringing together all functions related to project management and global settings

Intuitive Menus: Facilitating the Generation of Standardized Reports

Recognizing the importance of providing consistent reports to the end customer, TubePro 6 introduces menus that are more intuitive and user-friendly. This enhancement streamlines the inspection workflow and enables quicker access to essential features to further boost productivity.

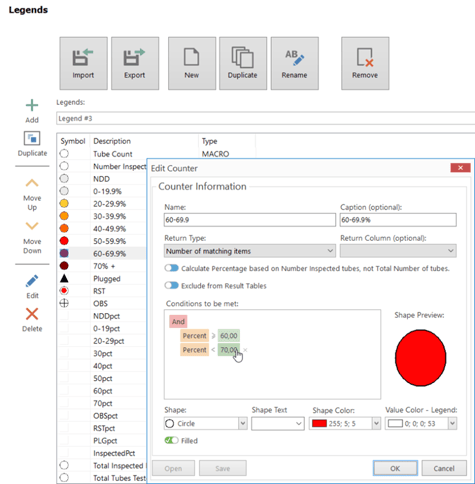

Managing report variables and legends is now performed through the dedicated backstage menu, providing enhanced control and customization of common parameters. The Legend Editor tool enables users to assign color codes to legend elements and fine-tune their settings from the backstage, while offering the capability to create multiple legends. Simultaneously, the Tube Map Results Table, accessible in the frontstage, merges the legend with the inspection data to create a detailed and easily interpretable result tables.

Merging the legend with inspection data for making a more comprehensive results table

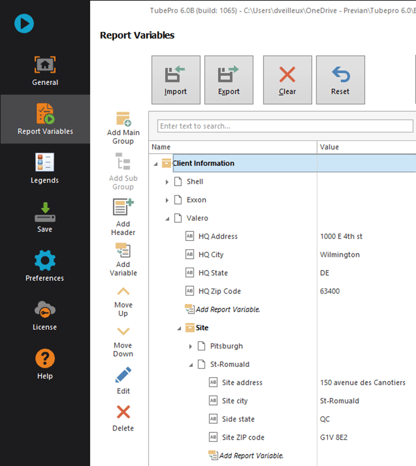

The Report Variable tool empowers users to effortlessly create complex information structures through a simple interface and standardize information across inspection teams. Once completed, the goal is to drag the appropriate variables from the Project panel in the frontstage and place them into predefined fields in the report template. The ability to link customers with various inspection sites on multiple levels ensures that analysts can swiftly locate pertinent information for their reporting needs.

Report Variables editor to simplify the input entry and management for any personnel generating a report

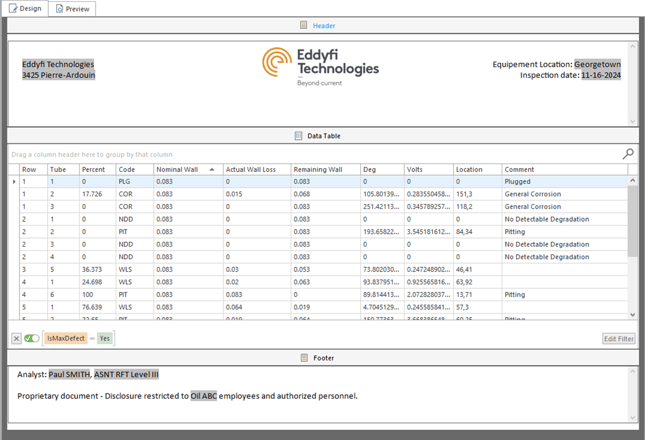

Upon transitioning to the Reporting phase, the imported data becomes pivotal in tailoring the Defect Table through an interactive editor menu. The introduction of a New Defect Table menu facilitates the creation and adjustment of result tables inserted in the final report with a more personalized and comprehensive presentation. The interactive editor menu empowers users to fine-tune header and footer information, select desired columns, incorporate report filters, preview changes in real-time, and explore additional customization options.

Defect Table: Tailor results with an interactive editor for personalized and comprehensive reporting

Expanding on the advancements within the Drawings view, drawing menus are redesigned to provide a more intuitive process for adding drawing elements. Users can now effortlessly integrate drawing elements such as 2D map sections and shapes while adjusting the overall drawing layout and alignment through a more interactive platform. Furthermore, the New View Editor in Drawings marks a substantial improvement in refining the presentation of 2D maps, particularly in distinct zones.

Conclusion

Eddyfi Technologies is committed to empowering non-destructive testing professionals with leading-edge software solutions. TubePro 6 represents our ongoing commitment to delivering a user-friendly experience, improved efficiency, and enhanced functionality. By moving to TubePro 6, users can experience a simpler user interface, streamlined workflows, faster processing times, and improved overall software speed. The latest version brings a variety of advantages, such as faster tubesheet creation, improved defect table management, and dynamic tube numbering display. The software's benefits are further evident in features like advanced tube selection tools, enhanced 2D map and legend editor tools, and a more intuitive interface for configuring software’s connection to Magnifi.

To support users in harnessing the full potential of TubePro 6, we also developed a comprehensive eLearning course that is available through the Eddyfi Academy. This online course covers various workflows within the software, empowering users to leverage the software's capabilities while ensuring continuous learning. We invite all professionals who are at the forefront of advancements in non-destructive testing and inspection with Eddyfi Technologies to explore the powerful features of this software and experience the difference firsthand.

Authors: David Veilleux, David Aubé, Vahid Shahsavari