Can the Gekko® and RMS PA with the PA-CAT™ technique be the answer to early detection of CUPS?

Many pipe support designs like resting or mechanically fastened supports allow water to collect between the support and the pipe surface, thus creating an ideal environment for crevice corrosion. CUPS often occurs due to a lack of proper inspection and maintenance of the affected areas which are more likely in areas with low visibility or inaccessible directly below the supports.

Figure 1: Simple Supports - Resting and Mechanically Fastened

When direct hands-on access to the corroded surface is restricted, it limits your inspection options. Lifting the pipe or implementing secondary supports to examine the areas of concern are typically avoided as the severity of the corrosion is unknown and the activity may increase the risk of failure.

Initial visual inspections are used to identify target areas, typically followed by Radiographic Testing (RT) or Ultrasonic Testing (UT) techniques. Quantification of corrosion can be difficult with RT as the corrosion measurement is based on film density which can differ significantly with slight variations in exposure angles and interference from the pipe supports. Ultrasonic tools using electromagnetic acoustic transducers and/or guided wave (like this one) have previously been used, but the implementation and signal characterizing differs from traditional UT. Ultrasonic testing is regarded as the most accurate Non-Destructive Testing (NDT) method for locating corrosion and providing measurements for remaining wall thickness and corrosion depth. This UT information feeds into integrity management systems, and engineers can determine the fitness-for-service and remaining life of components. Most UT technicians still rely on the understanding of conventional ultrasonic pulse-echo or pitch-catch techniques.

Figure 2: Eddyfi Technologies Gekko® portable phased array test instrument

A new technique called PA-CATTM for inspection of CUPS was developed by Canadian company Holloway NDT & Engineering Inc. The technique does not use specialized hardware but instead utilizes existing PAUT instruments, probes, and scanners like Eddyfi Technologies Gekko and RMA PA that are common to NDT service companies. A phased array approach produces a much more robust and information-rich dataset compared to mono-element techniques.

Figure 3: Eddyfi Technologies LYNCS™ scanner for weld inspection and corrosion mapping

Analysis is performed instantly using an online algorithm based primarily on amplitude modeling of real corrosion. Automated analysis provides several advantages over traditional methods, not the least of which is the elimination of variations between inspectors. Results are produced immediately by submitting a data subset to a cloud server along with inspection parameters such as pipe diameter and wall thickness. The corrosion profile, or “river-bottom”, is presented along with couplant efficiency results in a spreadsheet which can quickly be formatted to meet specific reporting requirements. This allows inspectors to produce repeatable and reliable data to which critical decisions can be based on.

The technique is currently applicable to pipes and vessels from a diameter of 100 millimeters (4 inches) and up, and thicknesses as low as 6 millimeters (0.23 inches). PA-CAT has proven reliable and repeatable for inspection of CUPS on both piping and vessels in blind trials and laser prove-up in real world applications both onshore and offshore.

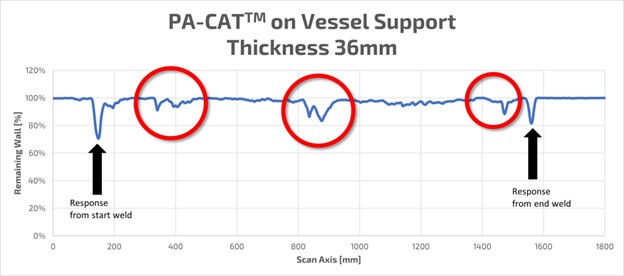

Testing the technology in the field

TRAC Energy Ltd. was forming a long-term strategy of investing in new inspection advancements. Eddyfi Technologies along with Holloway NDT carried out various trial inspections on associated pipework at 10 and 14 millimeters (0.39 and 0.55 inches) wall thickness, and vessel at 36 millimeters (1.41 inches) wall thickness for the inspection of CUPS. This trial inspection provided TRAC Energy with a greater understanding of the capability of PA-CAT, prior to the roll out to TRAC Energy’s client base.

This is just one example of where synergistic technology like the Gekko and RMS PA are a great candidate for detecting defects left otherwise unknown. How can we help you? Contact our NDT experts to discuss your specific inspection requirements today!

.png)