Ectane 3 - Unité d'acquisition de données multi-technologies

Le contrôle non destructif (CND) des tubes et des surfaces repose sur plusieurs techniques qui dépendent de l'application et du matériau concerné. Pour repousser les limites du CND avancé, l'Ectane 3 apporte la puissance de la technologie RFA pour les inspections d'échangeurs de chaleur ferreux.

Le RFA est la dixième technologie disponible sur l'Ectane 3. Qu'il s'agisse du contrôle par courants de Foucault (ECT), de courants de Foucault multi-éléments (ECA), de l'ECA tangentiel (TECA™), de la fuite de flux magnétique (MFL), du réseau MFL (MFLA), du contrôle en champ proche (NFT), du réseau en champ proche (NFA), du système d'inspection rotatif interne (IRIS), du contrôle en champ lointain (RFT) ou du RFA, les capacités intégrées polyvalentes de l'Ectane 3 permettent aux sociétés d'inspection de choisir l'outil optimal pour une large gamme de conditions d'inspection.

Figure 1 : Ectane 3 d'Eddyfi Technologies

Figure 1 : Ectane 3 d'Eddyfi Technologies

L'Ectane 3 intègre les dernières technologies électroniques et le boîtier IP65 est standard, offrant ainsi une protection totale contre la pénétration de particules ultrafines et de jets d'eau à basse pression provenant de n'importe quelle direction, ainsi que contre la condensation et les projections d'eau. Ceci étant dit, l'Ectane 3 convient à la plupart des applications extérieures exposées à des conditions météorologiques difficiles.

Pour en savoir plus sur les applications, les avantages et les caractéristiques de l'Ectane 3, cliquez ici.

Sonde RFA - Caractéristiques principales de la conception

Avec l'introduction de la technologie RFA, Eddyfi Technologies offre une expérience utilisateur intuitive pour une visualisation et une analyse efficaces des données sur les tubes en acier au carbone. La conception de la sonde RFA combine un double conducteur conventionnel avec deux bobines avec un réseau de bobines à haute densité, donnant à l'utilisateur l'accès aux deux réponses du signal pour une analyse plus approfondie.

Figure 2 : Sonde RFA (Remote-Field Array Probe) d'Eddyfi Technologies

Figure 2 : Sonde RFA (Remote-Field Array Probe) d'Eddyfi Technologies

Grâce à de multiples itérations et à des travaux de recherche et de développement approfondis, la conception finale associe un traitement du signal et une réponse à la pointe de l'industrie à une conception prête à être utilisée sur le terrain.

Voici les principales caractéristiques de cette nouvelle sonde RFA.

Boîtier de sonde robuste

Grâce à un manchon de protection en acier inoxydable, les bobines d'attaque, la bobine et les bobines du réseau sont protégées des facteurs environnementaux.

Connexion du câble plus solide et plus facile

Contrairement aux sondes RFT conventionnelles, la sonde RFA adopte un raccord à double arête pour générer une connexion plus solide entre la gaine souple (côté instrument) et la gaine rigide en nylon (côté connecteur), disponible en 20 mètres (67 pieds) et 30 mètres (99 pieds).

La sonde RFA utilise un connecteur à 41 broches qui peut être connecté à un Ectane 3 avec les options de réseau (modèle 64 ou 128) et de champ à distance (RNM). Le connecteur est équipé d'un écrou de couplage conçu sur mesure pour faciliter la connexion de la sonde à l'instrument de test Ectane 3.

Figure 3 : Connexion robuste du câble

Figure 3 : Connexion robuste du câble

Dispositifs de centrage interchangeables

Pour maintenir un décollage constant et fournir une réponse de signal de meilleure qualité, la sonde RFA est équipée de deux dispositifs de centrage interchangeables situés aux extrémités de la sonde. Ces dispositifs ont été spécialement conçus pour l'environnement impitoyable des tubes en acier au carbone. Composés de seulement trois pièces, ils n'utilisent pas de ressorts et peuvent être facilement démontés pour le nettoyage ou le remplacement des pièces. Les doigts de centrage sont en céramique pour garantir une bonne résistance à l'usure et une durée de vie plus longue.

Figure 4 : Dispositif de centrage de la sonde RFA

Figure 4 : Dispositif de centrage de la sonde RFA

Activation personnalisable du conducteur

Deux émetteurs sont positionnés à chaque extrémité de la sonde. Ils sont identifiés comme le conducteur principal, près du câble de la sonde, et le conducteur secondaire, à l'autre extrémité, selon l'idée que le conducteur principal est le premier conducteur à rencontrer un défaut lorsque la sonde est tirée vers l'opérateur, et que le conducteur secondaire est celui qui suit. L'une des caractéristiques de la sonde RFA est qu'elle peut être convertie en sonde à conducteur unique en désactivant l'un de ses conducteurs. La version 5.1 du logiciel Magnifi® permet à l'utilisateur de régler ce paramètre facilement grâce à l'assistant de configuration RFA dédié. Cette polyvalence permet d'augmenter la probabilité de détection (PoD) à proximité des plaques de support et des feuilles de tubes.

Figure 5 : Émetteurs de la sonde RFA

Figure 5 : Émetteurs de la sonde RFA

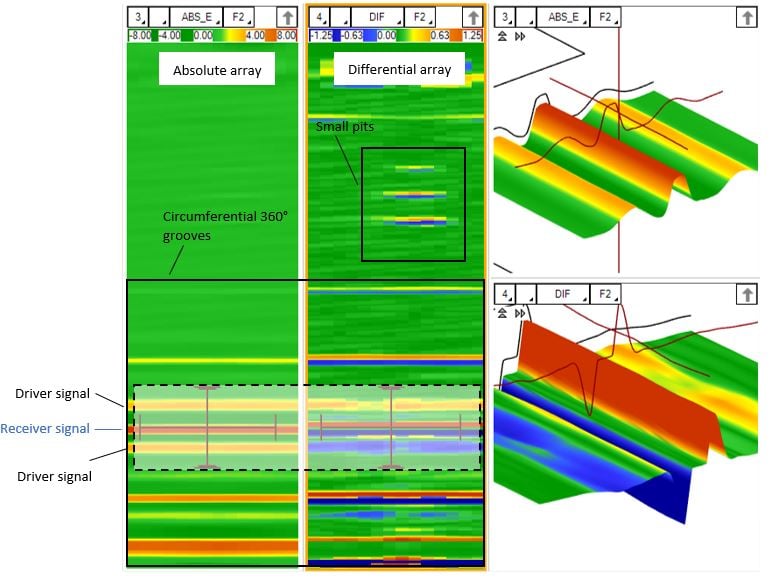

Données sur les bobines et les réseaux en un seul passage

La sonde RFA offre une combinaison de données de bobine et de réseau en un seul passage. La sonde comprend deux bobines circonférentielles qui créent des canaux absolus et différentiels comme les sondes RFT conventionnelles. Les signaux absolus et différentiels des bobines produisent des diagrammes en bandes, des plans de Lissajous et des plans de tension dans l'interface du logiciel Magnifi.

La partie réseau de la sonde consiste en deux rangées de capteurs qui couvrent la circonférence de la sonde. Le nombre de capteurs par rangée dépend du diamètre de la sonde. La deuxième rangée du côté du câble, qui est plus proche du milieu de la sonde, est utilisée pour créer les canaux absolus du réseau, et les canaux différentiels du réseau sont obtenus en soustrayant simplement les signaux d'une rangée de l'autre.

Figure 6 : Sonde RFA avec bobine et données de réseau

Figure 6 : Sonde RFA avec bobine et données de réseau

Imagerie C-scan 2D/3D à haute résolution

Grâce à l'intégration de la technologie des réseaux dans la conception, les analystes effectuant des inspections d'échangeurs de chaleur ferreux peuvent mieux comprendre la morphologie des défauts et améliorer la probabilité de détection. Les canaux de la composante réseau de la sonde sont combinés pour produire une imagerie C-scan à haute résolution.

En général, le canal du réseau différentiel convient à la détection de petites piqûres, tandis que le canal absolu est utilisé pour analyser des défauts volumétriques plus importants, tels que la corrosion ou les défauts de conicité. La figure 7 montre l'imagerie C-scan d'un étalon en acier au carbone. Comme le montre la figure, les défauts circonférentiels tels que les rainures à 360° sont facilement discernables des petites piqûres. À l'emplacement de défauts volumétriques plus importants, tels que la rainure de diamètre extérieur indiquée, les signaux reçus des conducteurs sont également visibles sur le C-scan. En outre, les images 2D/3D du scanner C permettent de localiser avec précision les petits défauts autour du tube. De plus, la capacité du réseau à distinguer les petites piqûres des gros défauts permet de détecter les piqûres plus près des éléments externes, tels que les plaques de support, que ce qui serait possible avec un RFT conventionnel.

Figure 7 : Imagerie par balayage C d'un étalon en acier au carbone

Figure 7 : Imagerie par balayage C d'un étalon en acier au carbone

Inspection RFA - Acquisition et analyse des données

L'instrument d'inspection Ectane 3 et le logiciel d'acquisition et d'analyse Magnifi version 5.1 ou supérieure sont nécessaires pour les inspections RFA. L'Ectane 3 et le Magnifi sont conçus pour prendre en charge la technologie émergente des réseaux de champs lointains, dans le but d'optimiser l'analyse des données.

Les opérateurs équipés de la technologie RFA d'Ectane 3 et de Magnifi peuvent collecter des images C en temps réel, rapidement et avec précision, pour une évaluation fiable des échangeurs de chaleur. Des outils dédiés, y compris, mais sans s'y limiter, des canaux de réseau spécialement conçus, un filtrage avancé et des options de palette de couleurs polyvalentes, sont conçus et intégrés dans Magnifi pour optimiser l'affichage des signaux C-scan afin que vous puissiez voir les vraies couleurs de votre actif.

Vous souhaitez en savoir plus sur la technologie RFA? Restez à l'écoute pour plus d'informations et abonnez-vous à notre blog pour recevoir des mises à jour hebdomadaires directement dans votre boîte de réception.

Eddyfi Technologies offre une gamme de technologies d'essais non destructifs pour inspecter les échangeurs de chaleur ferritiques. Contactez-nous pour savoir quelle sonde convient le mieux à votre application spécifique et pour vous tenir au courant.