Eddyfi Technologies leverages a broad range of expertise company-wide to provide specialty engineering in accordance with design criteria; reliability, efficiency, quality, and cost-effectiveness are emphasized in the design of all our remote tooling and industrial robotic solutions. From ideation to delivery, we offer engineering services from conceptual design through to project completion, made possible by a strong leadership team and process for delivery.

Custom robots for remote industrial challenges

VersaTrax™ OnSpec crawlers are the result of an agile project management design scheme. Armed with more than 330 years of robotics expertise, proven modules, and an adaptive approach, our iterative process offers the flexibility and velocity to efficiently deliver a remote-controlled robotic solution that can address your exact industrial requirement. We go beyond mechanical to software, electrical, and communication demands and seamlessly integrate proprietary or third-party tooling and components. Our project delivery and services are all to your specification: we define, detail, build, integrate, and perform factory acceptance and/or onsite testing all to spec.

Designed with performance and reliability in mind, Eddyfi Technologies’ OnSpec custom robotic solutions are purpose-built for repair, maintenance, retrieval, and numerous other remote tooling applications. We provide customers with innovative, high-quality equipment that is functionally reliable, easily operated, cost-effective, and developed to address the world’s toughest environments or areas simply out of reach.

We have a long history of creating specialized solutions for remote challenges left previously unsolved. OnSpec robotics have been employed for cross-border patrol, suspicious package reconnaissance, floating production storage and offloading (FPSO) cleaning, tool recovery, wire installation, offshore painting and fabric maintenance, and so much more. The applications for our adaptable robotic crawler technology are seemingly endless.

Testing the waters: OnSpec sampling robot

We keep saying that our technology allows for the re-configuration of proven robot and camera modules to expand capabilities for specific inspection and remote operation requirements. But what does that really mean? In a lot of cases, it’s the difference between success and failure – especially where tight timelines come in to play.

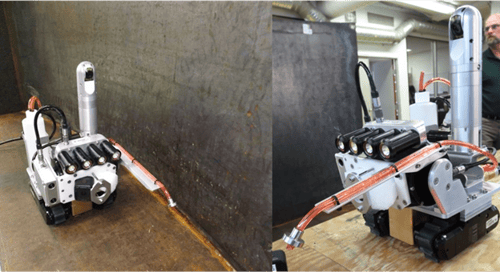

Case in point: this OnSpec custom robot, based on the VersaTrax™ M-Series (formerly known as Magg™) miniature magnetic inspection crawler, was redesigned for a specific project at a nuclear facility operated by a large power generation company. They needed a small robot that could access, inspect, and take water samples inside of a transfer tunnel.

In order to prevent deterioration of aluminum clad fuel elements, maintaining excellent quality water is key. Water is commonly used to reduce the heat generated by a nuclear reactor. It is also typically used to store spent fuel elements once removed from a reactor core. A well-controlled environment will show minimal to no signs of corrosion. When implementing a corrosion surveillance program, the sampling program plays a critical role in a water quality management system. Common locations for sampling in a nuclear plant include ventilation exhaust ducts, drains, sumps, and waste tanks.

Online measurements of water quality parameters like pH, conductivity, and temperature enable a quicker response to any deviations from normal operating conditions, and any corrective actions can be safely taken as required. On the other hand, offline measurements allow measurements from regions where online measurements are not possible. More detailed analysis of the water composition can be performed during these shutdown periods.

For this application, we modified the VersaTrax to incorporate two of the client’s GoPro cameras onto a tilting mechanism at the front of the vehicle. We also designed a new water sampling system using a peristaltic pump. An onboard Spectrum™ camera was incorporated to provide real-time monitoring of both the water level in the sample bottle as well as the position of the GoPro cameras.

From start to finish, the project took only three weeks to complete, including all of the design, assembly, and shipping. The client received the system in time and successfully completed their nuclear inspection and monitoring project during the scheduled outage.

Check out where Eddyfi Technologies’ robotic solutions have been used elsewhere in the nuclear industry:

- Nuclear reactor primary piping inspection

- Nuclear remediation efforts

- Nuclear waste storage unit assessment

How can VersaTrax OnSpec robotics help you? Let’s find out.

If you have a project with aggressive schedules or demanding performance criteria, put our OnSpec robotics technology to the test! Contact us to learn about available options to power your remote tooling challenges today.

.png)