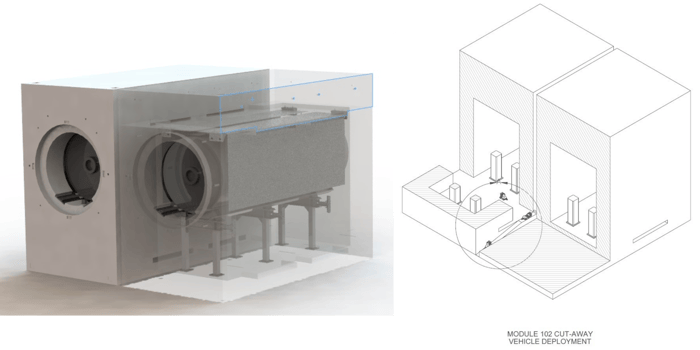

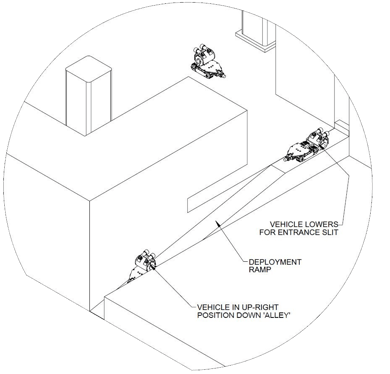

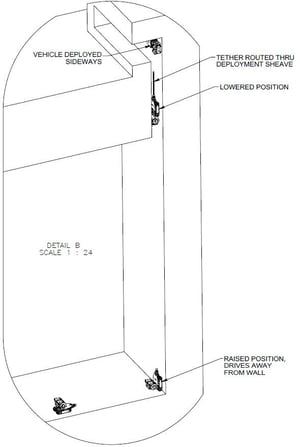

The project required consideration for a number of challenges. Not only did the inspection robot need to enter the concrete vault modules by maneuvering through a sharp corner roof vent only 30 centimeters (12 inches) high, but the robotic crawler also had to operate in significant nuclear radiation combined with maximum temperatures of 60 degrees Celsius (140 degrees Fahrenheit).

To complicate matters even further were the stringent optical resolution requirements for the inspection crawler to supply an imaging system capable of resolving AREVA TN’s VT-3 Vision Card (an in-house image resolution test) in complete darkness, all while travelling through the narrowest areas at the bottom of the storage units.

-1.png?width=700&name=My%20Post%20(1)-1.png)

.png?width=500&name=My%20Post%20(3).png)

Drawing from a long history of designing, manufacturing, and selling remotely operated robotic camera and crawler systems, Eddyfi Technologies’ robotic experts designed an OnSpec custom robot based on the commercially available Magg™ magnetic crawler. The OnSpec custom robot incorporated a high definition 360-degree continuous tilt camera head and a narrow, customized chassis with a camera raise function for lowering the camera head for deployment and raising to have a clear view forward and behind. The VT-3 compliant crawler used two wide angle flood lights and two narrow beam LED spotlights to provide the illumination required in the completely dark environment.

Big functionality in a small package, the final result of the heavy-duty robotic inspection crawler, with a fully integrated bespoke InfraRed (IR) temperature sensor, effectively performed the remote inspection needed of the radioactive waste storage containers. See the factory testing video below.

While most of our products are well suited for the inhospitable nuclear environments, sometimes an OnSpec custom robot may be required for atypical conditions. Contact our team to learn about the best remote visual inspection and nondestructive testing solutions for your operations today.

.png)