While each system has its advantages, for most confined space entry or CSE applications, a tethered inspection robotic crawler provides the most reliable and efficient option. Let’s take a look at some of the key advantages here.

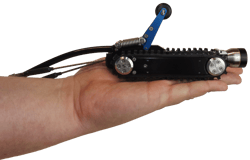

Eddyfi Technologies’ remote visual inspection, or RVI, robots enable access to areas that are too dangerous or distant for direct human intervention. This is accomplished through a signature small and modular design; the size and weight of our inspection robotic crawlers are reduced significantly by eliminating the need for an onboard power source. With a minimal footprint, Eddyfi Technologies’ miniature magnetic crawlers and pipe inspection vehicles can traverse through narrow openings, congested locations, and extremely confined spaces. Tethered inspection robotic crawlers can also travel further distances and operate indefinitely, unlike battery powered vehicles which have limited mission life between charges.

On the topic of taking the lead, our inspection crawler tethers incorporate extra strength components so they can be used to lift or lower the vehicle during work-at-heights and/or confined space entry operations. For example, the VersaTrax™ pipe inspection robot can be deployed through a manhole into the opening of a pipe or penstock without having to rely on a crane or arranging for alternative access to the entry point.

Moreover, the tough tether can be used in the unlikely event of a malfunction requiring emergency extraction of the system. Considering that these NDT robotic workhorses are examining areas that are impossible or unsafe for humans to enter, a tether provides a lifeline for your long-distance inspection crawler robot (learn more about removing the risk of confined space entry with robotics here). Tethered remote visual inspection robotic systems can also offer better control and navigation than unmanned aerial vehicles, or UAVs, that are subject to unpredictable conditions like unyielding weather.

Eddyfi Technologies Robotic Crawler Performs Drone Recovery Inside Vessel

Using a remotely operated, tethered NDT robot by Eddyfi Technologies provides a devoted link for communication between the control unit and the robotic inspection crawler. On the other hand, wireless systems may be subject to external factors such as nearby electrical noise or they may be simply incapable of transmitting through some materials. A wired communication is the best way to ensure uninterrupted transmission for remotely operated mobile robots working in environments like tanks and pressure vessels or pipelines common in the energy, power generation, and water industries to name a few. Real-time data transfer is achieved for longer periods without breaks; talk about lights, camera, actionable insights!

So… what’s the downside? Tether cables are a pain. They can limit the ability to drive around multiple bends, they can get caught on debris or other objects, and if they aren’t managed properly, they can be a hazard (people trip over them!). We mitigate some of these issues by incorporating a rear tether monitoring camera on most of our remote visual inspection robots. Plus, when employing Eddyfi Technologies’ industrial cable handling reels and winches, you ensure safe and reliable operations while decreasing tether wear and tear. At the end of the day, when you’re working in challenging real-world environments and/or extremely confined spaces, the benefits of an agile tethered inspection robot outweigh the drawbacks. Paired with best-in-class technologies for phased array ultrasonic testing, alternating current field measurement (ACFM®), and eddy current array - Eddyfi Technologies inspection robots are truly leading (no pun intended) by example when it comes to the future of NDT.

We recognize that choosing the right robotically deployed inspection technology for your business is a complex decision – one that goes beyond quality, reliability and craftsmanship. We know it’s about identifying the NDT robot best adapted for your precise needs. Learn more about how to leverage an Eddyfi Technologies robot with your NDT toolkit here. Why not reach out to our dedicated experts for a data-driven dialogue on an innovative solution today? Better yet, request a demo and see precisely how our proven robotic crawlers can address your unique inspection challenges and keep you Beyond Current.

.png)