TFM algorithms create an image by calculating the ultrasound travel time between every transmit-receive element pair with each pixel in a grid, and assigning the amplitude based on the time between an A-scan and pixel point. Compared to conventional phased array sweeps, TFM images can optimize Probability of Detection (PoD) and make analysis more intuitive. With a 64-channel parallel architecture, the Gekko® is the only available instrument offering real-time TFM with up to 128 channels — ensuring field proven and time efficient inspections. It offers higher resolution TFM, up to 250k pi, for thick weld, aluminum block and bolt inspection; High Temperature Hydrogen Attack (HTHA) and corrosion mapping.

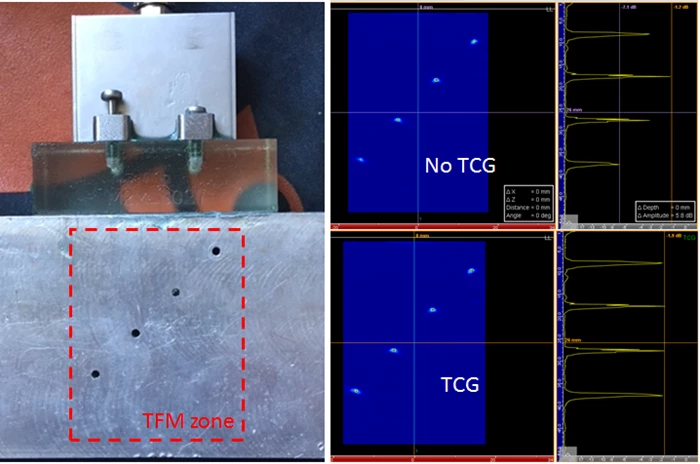

While the TFM image may be clear, image intensity isn’t naturally uniform across the grid. Ultrasonic energy declines as it gets further away from the surface of the element. Beam spread and material attenuation are responsible for this energy loss, with distribution being irregular over the test region. In order to compensate for disruptive effects, a calibration process is required. Time-Corrected Gain (TCG) is a tool that counteracts reduced signal amplitude by increasing the system gain with time so that the echo height of a calibration reflector is uniform at any position along the time base. All signals under assessment are then at the same Full Screen Height (FSH) percentage, typically 80%, regardless of their distance. TCG enables same size defects no matter how far away they are as time and distance can be interchanged. TFM with TCG allows a large zone to be observed simultaneously, with Gekko checking all defects together.

If the thought of calculating a corrective formula to overcome material attenuation, nearfield effects, and beam spreading to equalize amplitudes across TFM images sounds intimidating, we’ve got some great news. You. Don’t. Need. To.

Gekko and Mantis™ ultrasonic flaw detectors feature Capture™ software which offers automatic TCG for Phased Array UT (PAUT), Time-of-Flight-Diffraction (TOFD) and TFM. For uniform sensitivity on all image points, TCG is activated by using an onboard wizard that generates a TCG-curve within a few clicks – it is no longer operator dependent. If you’re up for manually entering depth related gain values, this is an option (usually when a suitable calibration block is unavailable). Did we mention that there’s a wizard that ensure your TFM weld inspections are code compliant?

Check out this blog post clearly demonstrating the value of code-compliant TCG with TFM. When the TCG isn’t applied, the variation in amplitude between minimum and maximum calibration holes is about 6dB. The Gekko® is the advanced solution that fully takes advantage of FMC data with TCG and TFM. Get in touch to learn more today.

.png)