Bursting the Bubble on Current Inspection Methods

The existing inspection protocols present a growing concern, especially when we take into account their inherent limitations. As mandated by BS EN 12485, periodic inspection of pipework and supports are essential. However, these inspections predominantly rely on visible assessments, leaving uncharted territories in the form of inaccessible sections of pipework that might be compromised. Even when these inspections cover visible areas, they may overlook subtle signs of corrosion, posing a significant risk to the entire system's integrity. A weekly check for water line pressure is part of the requirements, but offers only limited insights, primarily identifying pinhole leaks, while failing to address incipient corrosion within the sprinkler pipework.

Recognizing the urgency of this situation, the market demands a practical and swift solution to assess the corrosion status of these challenging, non-visible segments of sprinkler pipework, all before they lead to catastrophic through-wall defects. Enter Eddyfi Technologies.

Guided Wave Ultrasonic Testing for Sprinkler Systems

Our first method leverages guided wave ultrasonic testing through the innovative Sonyks™ instrument, enabling comprehensive pipe section inspection without the need for continuous probe movement. Unlike conventional ultrasonic testing, which operates in the MHz frequency range and primarily focuses on assessing remaining wall thickness, guided wave testing (GWT) utilizes low-frequency ultrasound in the 20-150kHz range. This unique frequency range allows GWT to direct ultrasound waves outward from the tool and propagate them axially along the pipe.

%20diameter%20pipe%20and%20128kHz%20test%20frequencycture1.jpg?width=600&height=496&name=6mm%20(4in)%20diameter%20pipe%20and%20128kHz%20test%20frequencycture1.jpg)

Figure 1: Sonyks Magneto-tool for 101.6mm (4in) diameter pipe and 128kHz test frequency

When these transmitted ultrasound waves encounter variations in cross-section, changes in acoustic impedance generate echoes that return to the tool for precise detection. By using reference points like welds or pipe ends for calibration and comparing signal amplitudes to these markers, GWT can not only identify corrosion but also measure its severity.

Traditionally, guided wave testing has been predominantly used for long-range ultrasonic testing (LRUT) in the energy industry. However, the real breakthrough comes from applying guided waves to medium-range ultrasonic testing (MRUT) in the context of sprinkler systems. MRUT employs higher frequencies exceeding 100kHz, resulting in shorter pulse lengths for the transmitted ultrasound. This leads to improved resolution, heightened sensitivity, superior defect detectability, and precise defect localization.

MRUT Case Study

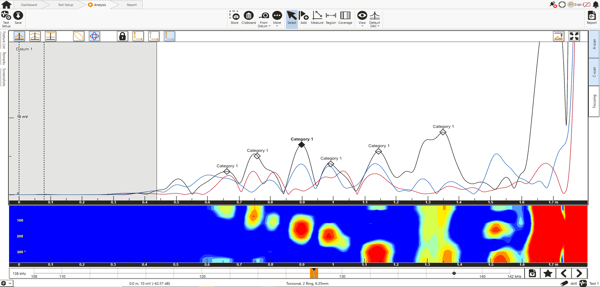

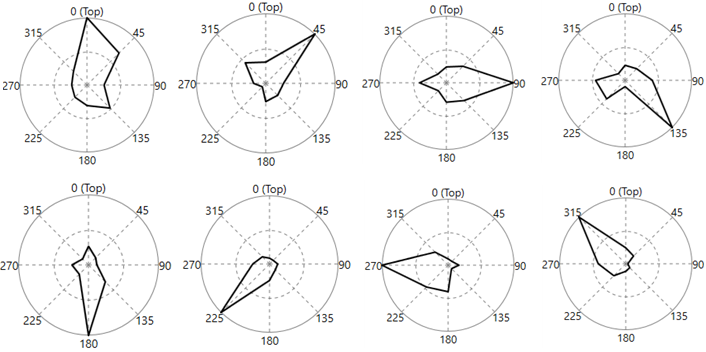

A calibration pipe measuring 114 millimeters (4.5 inches) in diameter with a schedule 80 wall thickness of 8.56mm (0.337in) was used as a pretest, as explained in this article. The pipe, 1.83m (6ft) in length, featured 1.5mm (0.06in) drilled holes at 45° intervals and a thinned section extending 76mm (3in) in length. The MRUT 4in Magneto-tool with Sonyks software was used for the inspection, positioned at the pipe’s end for ease of interpretation due to its short length. The inspection yielded excellent signal-to-noise ratio (SNR), detecting all eight defects, as evident in the C-scan. The thinning between 1.29-1.37m (4.2-4.6ft) was also identified circumferentially. Secondary focusing allowed detailed examination, mapping the rotation of defects from 0° to 315°. This data is displayed in Figure 4 and Figure 5, showing defect locations and rotations.

%20test%20pipe.png?width=600&height=273&name=Diagram%20and%20schematic%20of%20a%20114mm%20(4.5in)%20test%20pipe.png)

%20test%20pipe.%202.png?width=600&height=238&name=Diagram%20and%20schematic%20of%20a%20114mm%20(4.5in)%20test%20pipe.%202.png)

Figure 2: Diagram and schematic of a 114mm (4.5in) test pipe.

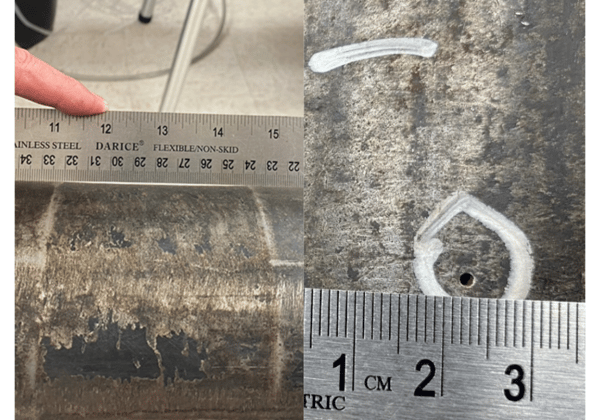

Figure 3: Close up photographs of the drilled holes and the thinned areas requiring detection.

Figure 4: A-scan and color map of the data showing the defects in the pipe. The colored spots correspond with the defects and the rotation of these spots match identically with the rotation of the defects on the pipe.

Figure 5: Focusing showing the rotation of the defects with distance from 0° to 315°.

Magnetic Flux Leakage for Sprinkler Systems

The second solution presented for better assessment of potential corrosion in industrial sprinkler systems is magnetic flux leakage. It offers a different approach to corrosion detection by detecting the volume of missing magnetic material. Pipescan HD by Eddyfi Technologies is designed to tackle corrosion with speed, reliability, and robustness. It maximizes Probability of Detection (PoD) by providing immediate data, optimizing workflows, and ensuring verifiable, recorded results. Deployment is simple, with a unique single curvature adjustment tool that streamlines the inspection setup. No couplant or complicated gate settings are required. Operators simply connect the Pipescan HD to the data acquisition instrument, enter the inspection details, and are ready to go.

Figure 6: Pipescan HD deployment inspecting pipe for corrosion.

MFL Case Study

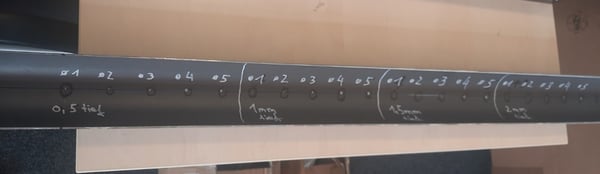

During the inspection of a bisected sprinkler pipe to evaluate sensitivity, a range of defects was identified. These defects varied in depth from 0.5mm (0.02in) with diameters spanning 1 to 5mm (0.04 to 0.2in), and in the subsequent section, there were 1mm (0.04in) deep defects with diameters of 1, 2, 3, 4, and 5mm (0.04 to 0.2in), as depicted in Figure 7.

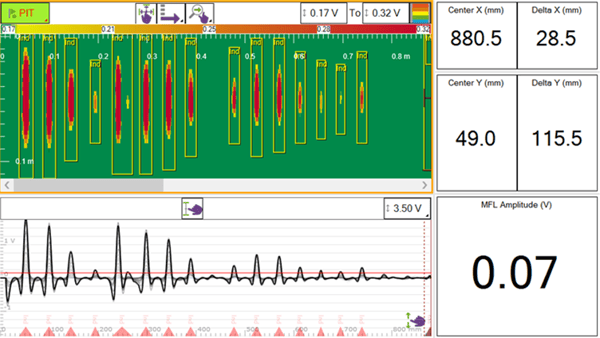

This inspection, completed in a single pass, took approximately 15 minutes, encompassing setup, scanning, and report generation. Most defects were easily discernible, as depicted in Figure 8. Upon categorizing the results by depth, all five defects in sections 1, 2, and 3 with depths of 2.0mm (0.08in), 1.5mm (0.06in), and 1.0mm (0.04in), respectively were clearly visible within the dataset. In section 4, which featured 0.5mm (0.02in) depth defects, three defects were distinctly visible, highlighting the exceptional sensitivity of the Pipescan HD equipment for this inspection.

Figure 7: Sprinkler pipe section with simulated corrosion defects of various depths and diameters.

Figure 8: Software clearly showing the different corrosion defects within the pipe sample.

Two Technologies Invite a Watertight Approach

Eddyfi Technologies introduces cost-effective solutions tailored for sprinkler systems, seamlessly merging corrosion sensitivity with user-friendly efficiency. The Sonyks guided wave testing system excels in assessing extended lengths of sprinkler pipes from a single location, eliminating the need for tool movement, while demonstrating remarkable sensitivity to even the smallest corrosion anomalies, as minute as 1mm (0.04in) through-wall holes. In contrast, the Pipescan HD equipment requires traversal across the inspection area but offers heightened sensitivity, capable of detecting wall losses of less than 1mm (0.04in).

Both NDT equipment solutions provide robust options for efficiently inspecting extensive sprinkler pipework, particularly in situations where uncertainty surrounds potential corrosion locations or where to initiate the inspection. Check out the Eddyfi Academy to learn more about GWUT and MFL technology.

When you’re ready to make it rain on your terms, contact our team of experts to discuss your next inspection project and how GWUT and MFL can keep your operations Beyond Current!