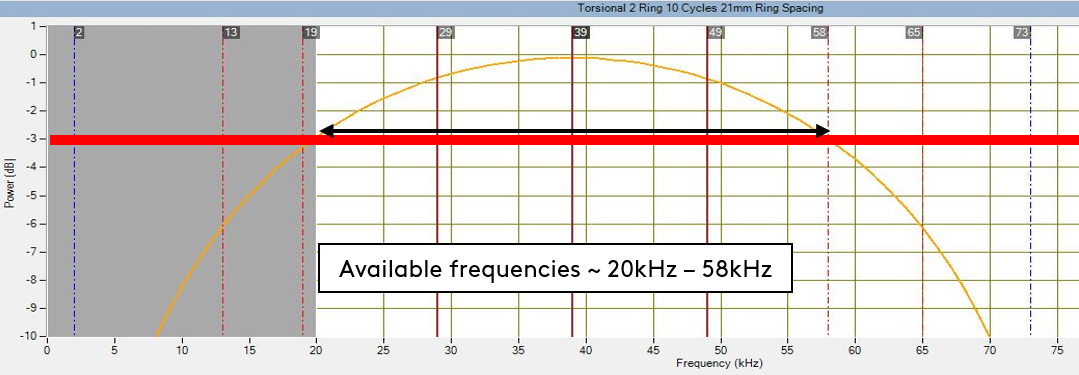

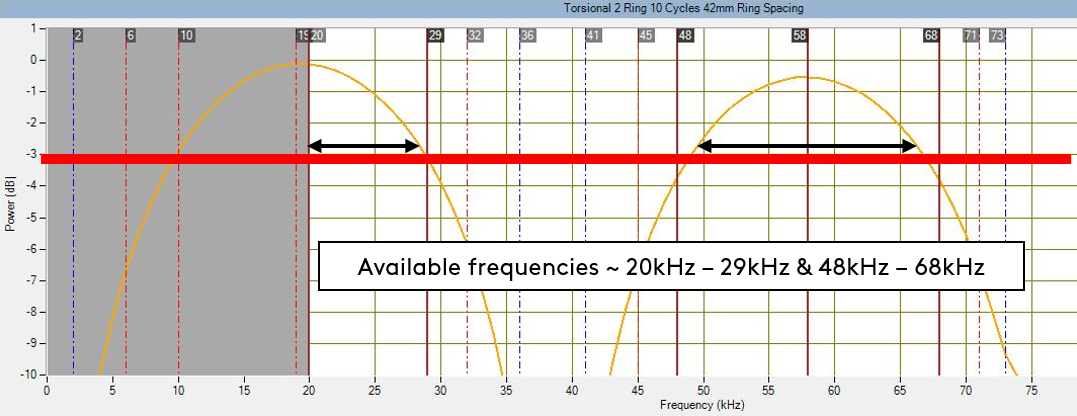

There any many different types of guided wave collars available depending on the manufacturer. For torsional wave, most collars available employ a two-ring system with various ring spacing options. The spacing between the transducers influences which frequencies are available for testing. Typically, with two-ring systems, there is an optimum frequency range at which the rings produce higher output signals due to constructive interference. There is also a frequency range in which the opposite happens; the output of each ring is reduced by destructive interference.

Let's look at some examples.

Figure 1: Power output curves for 2 ring 21mm (0.8in) spacing

Figure 2: Power output curves for 2 ring 42mm (1.7in) spacing

The ring spacing options illustrated in figures 1 and 2 are commonly used by another manufacturer of equipment. Having the two-ring spacing option in this case requires the use of three rings which requires moving cables between connectors. This tool delivers a total available frequency range of 20kHz to 68kHz, with the second ring spacing option only providing an extra 10kHz of usable frequencies.

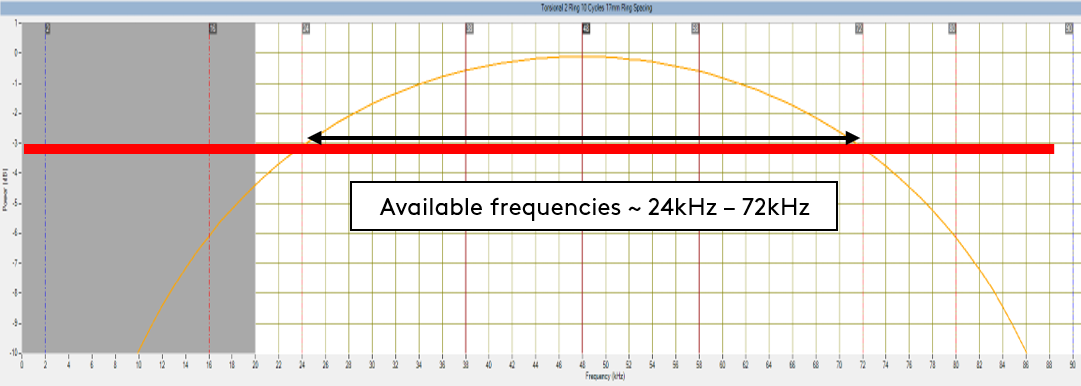

The new Sonyks™ long range ultrasonic testing tool employs the optimum ring spacing option of 17 millimeters (0.7 inches).

Figure 3: 2 ring 17mm (0.7in) spacing

This ring spacing option provides a broader range of usable frequencies compared to other commercially available technology without the need for an additional ring of transducers or changing connections between tests.

A wider range of frequencies with fewer total transducers and less connections!

In addition to having a wider range of frequencies at its disposal, you may wonder what other features the new Sonyks collar offers.

Using fewer transducer rings allows packing more transducers around the circumference, enabling Eddyfi Technologies to divide the tool into more radial segments. Most segmented guided wave tools have eight segments giving a radial resolution of 45 degrees. The Sonyks collars now have more segments depending on the diameter. For example, our 200-millimeter (8-inch) collar has 10 segments giving a radial resolution of 36 degrees, and our 250-millimeter (10-inch) collars have 12 segments giving a radial resolution of 30 degrees. This increase in radial resolution means that the Sonyks tool can provide more accurate information on the size of a defect. Operators scan at more circumferential positions now, improving both C-scan and focus resolution.

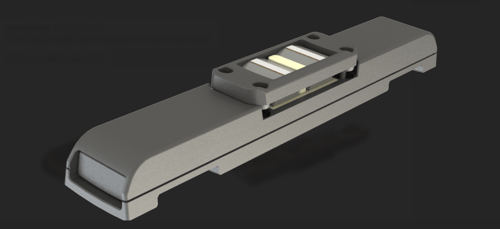

Not all improvements to the new Sonyks piezo tools are technical. There have also been many practical improvements, for example, the single connector.

It's the first piezoelectric collar with an actual single connector at both the collar and unit end. This feature simplifies the setup process and, along with other Sonyks features, offers significant productivity improvements.

The piezo collars are now equipped with a newly designed quickfire latching system. This new feature means that the tooling can be attached and removed from the pipe quickly and simply, without the need for any manual force. I know this can be an issue with some collars on the market.

The design team put a lot of thought into the new Sonyks collars; they are much more flexible making them more portable, easier to pack, and ship. The level of detail in the design has surprised early customers by providing subtle features that they didn’t know the needed but now cannot do without like the addition of D rings to lift the tool via lifting lines and carabiners. This feature is handy when deploying the system offshore when rope access is required.

To summarize the experience of using the new Sonyks piezo-tooling, it has been a revelation to use in the field. With the broadest frequency range, its lightweight and portable nature, along with a single connection between the instrument and the collar all make the Sonyks piezo-tool genuinely best in class. Don’t take my word for it though, request a remote demo with our team!

Eddyfi Technologies is dedicated to providing the industry leading technology responsible for helping keep everything, everywhere, and everyone safe. Contact us to discuss your next inspection challenge and stay Beyond Current.