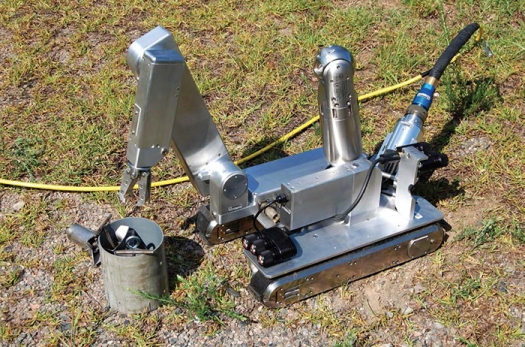

The scope of this custom robotics project was to supply a Nuclear Waste Sampling Crawler (NWSC) for heel characterization and sampling within the waste storage tanks. The NWSC enters an area with debris, obstacles, and radiation doses of approximately 100rem/hour. The robotic platform requires a 6-function manipulator arm to assist operators in all sampling missions.

The NWSC was developed to be an iterative design like past custom robots, with many new Eddyfi Robotics technologies applied. This crawler has better performance in many areas compared to the original design.

The NWSC supports one main navigation/inspection Spectrum™ 120 camera and up to four auxiliary cameras. The main navigation/inspection Spectrum camera provides primary HD video for the operator to navigate the difficult spaces and features inside a nuclear waste tank; the auxiliary cameras all share a video channel and can be switched from camera to camera. The auxiliary cameras allow for the operator to have a complete understanding of the vehicle’s physical state and the environment it must traverse.

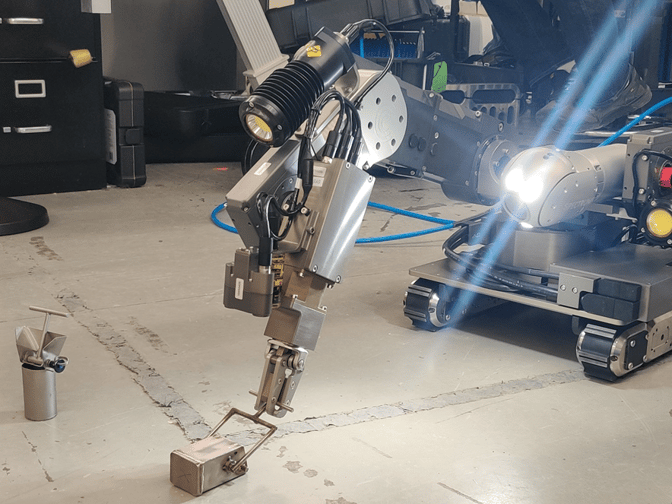

A 6-function manipulator arm is included as part of the robotic crawler system. To assist with arm use, there is an additional auxiliary camera and laser line indicator to measure and ensure the arm is properly sampling nuclear waste.

The NWSC was designed for challenging environments. With its flat chassis, spring tail, and adjustable weight, it's all about mobility and stability.

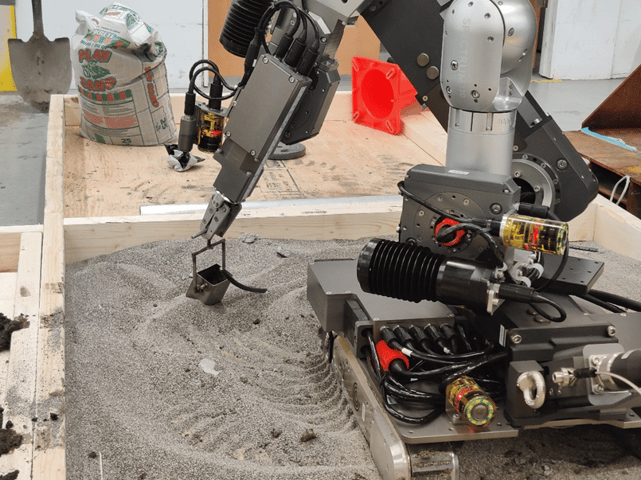

While traversing the nuclear storage tank, the crawler is supplied with different tools (i.e., ramps, baskets, sampling bottles) to complete its critical mission. At times, the vehicle must traverse significant obstacles to ensure accurate sampling at specific sites. The introduction of a new 6-degree-of-freedom (6DOF) manipulator equips the crawler with the necessary capabilities to accomplish this impressive task.

This manipulator arm builds upon the success of the 4-function manipulator which was installed on the original robotic platform. The two additional functions include another rotate joint giving the arm an ‘elbow’, as well as a lateral motion rotate ‘shoulder’ allowing the whole arm to access much more space around the crawler.

There are three cameras installed on the 6-function manipulator: a Spectrum 120 camera which is the main camera of the system, a static rear-facing camera, and a wrist-mounted camera to assist the operator to view the end of the manipulator jaws.

In addition to the wrist-mounted camera, there is a parallel laser line module to help the operator align the arm to grab or manipulate an object from the environment. Onboard lighting helps illuminate the working area. The whole arm is mounted to a lateral rotate actuator enabling the operator to access objects from many different positions.

In a leap forward for efficiency, our custom robotic project delivers enhanced functionality to ICON™ software. With this innovative plugin service, users can seamlessly control multiple actuators simultaneously. ICON retains its default features, but by simply loading a plugin file, users gain access to a whole new level of customization and ease. Eddyfi Technologies’ plugin revolutionizes control, shifting focus from individual joint manipulation to intuitive gripper positioning. By modifying the end effector's XY position and Z height, users effortlessly dictate movement, while the plugin handles the complex kinematics behind the scenes. Talk about a flex!

Conclusion

The NWSC heralds a new era of precision and control, offering operators the tools they need to manipulate, transport, and sample waste with exacting detail in even the most formidable environments. By facilitating the final steps of a nuclear waste tank's remediation process, this innovative technology ensures that every action is carried out with the utmost accuracy and efficiency, paving the way for safer and more effective cleanup efforts.

What remote industrial challenge can we help you solve? Contact our team of robotics experts to discuss!

.jpg)