Enhanced Compatibility and Flexibility

Recent updates maximize the capabilities of UltraVision, providing invaluable resources for users of Gekko®, Mantis™, and Panther™ systems. By integrating these data file formats for analysis, the software fosters greater interoperability and offers UT analysts the flexibility to select the most suitable analysis tool for their specific needs.

Advanced Analysis for Capture Users

While Capture software is renowned for its robust and intuitive inspection and analysis features, the latest update enriches this experience by making available UltraVision's advanced data analysis and processing capabilities. Enhanced features now include file and volumetric merging and advanced viewing options, allowing users access to the largest set of tools for UT data analysis.

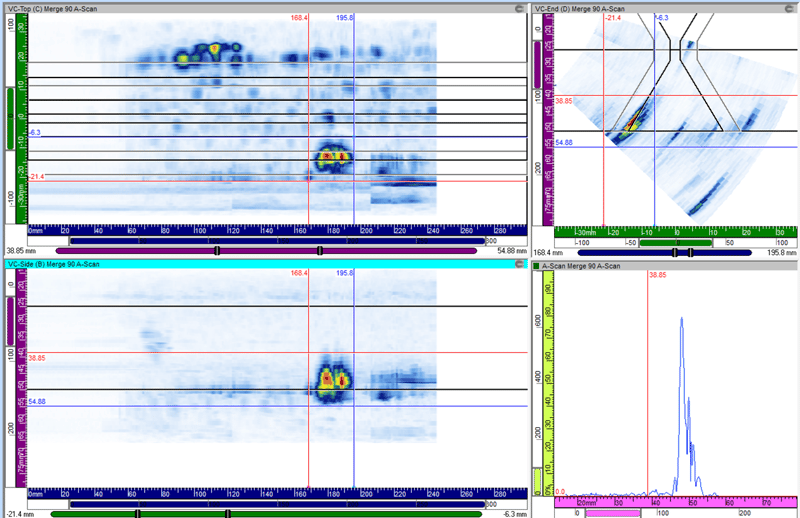

Volume Correction and Projected Views

Both Capture and UltraVision provide volume-corrected data analysis in top (C), side (B), and end (D) planes, converting angle beam data into true Cartesian views. This transformation presents a top view similar to traditional radiographs, contrasting with the often-uncorrected C-scan perspectives present in other software. UltraVision’s ‘Projected Views’ further enhance this by isolating and displaying data volumes in three dimensions, facilitating rapid identification and sizing of indications across scan positions without needing to examine individual data slices.

Figure 1: Projected Views in UltraVision

Seamless Data Integration with Volumetric Merging

For complex inspections, such as welds inspected from multiple angles or raster scanning tasks, UltraVision’s ‘Volumetric Merge’ function is invaluable. It consolidates multiple UT beams and channels into a single data volume, presenting it as a new channel for streamlined analysis. This feature, combined with advanced ‘Projected Views’, provides an optimized perspective for thorough and efficient review.

Figure 2: Volumetric Merge of 90 +270 Skews

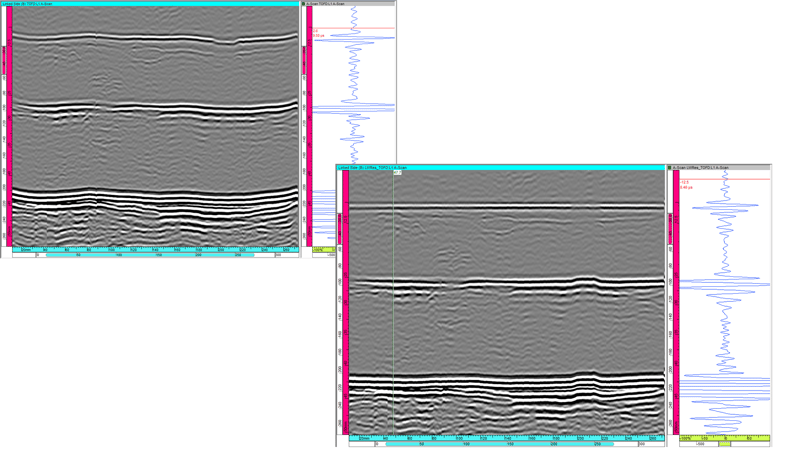

Advanced Time-of-Flight Diffraction Calibration and Processing

UltraVision software supports detailed recalibration and processing of Time-of-Flight Diffraction (TOFD) data. This includes lateral wave straightening, removal, and synthetic aperture focusing technique (SAFT) processing, enhancing the accuracy and capability of TOFD inspections.

Figure 3: Lateral Wave Straightening

Enhanced C-scan Processing

UltraVision software offers sophisticated tools for improving C-scan images, including the generation of new C-scans from stored data and various filtering options. C-scan stitching enables the integration of multiple scans into a unified view, which is particularly useful for large-area inspections, such as corrosion surveys.

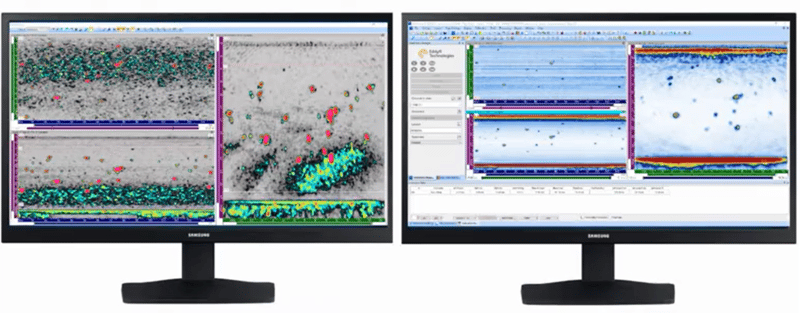

Multi-Screen Support for Efficient Analysis

A significant upgrade in UltraVision is its support for multiple screens. This enhancement allows Non-Destructive Testing (NDT) analysts to utilize expansive screen real estate, displaying different layouts and views simultaneously from the same file. This feature greatly improves the efficiency of the data review process.

Figure 4: UltraVision Multi-Screen Support

Explore UltraVision’s Full Capabilities

UltraVision software by Eddyfi Technologies is packed with advanced analysis features designed to meet diverse inspection needs. To explore the tools that best fit your applications or for information on software pricing, please visit our website. For personalized assistance and to fully leverage this powerful update, contact our team of experts.